Method for preparing vanillin from straw lignin under normal pressure condition

A technology of straw lignin and vanillin is applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc. Mild and controllable, the effect of solving the complex high temperature and high pressure equipment and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

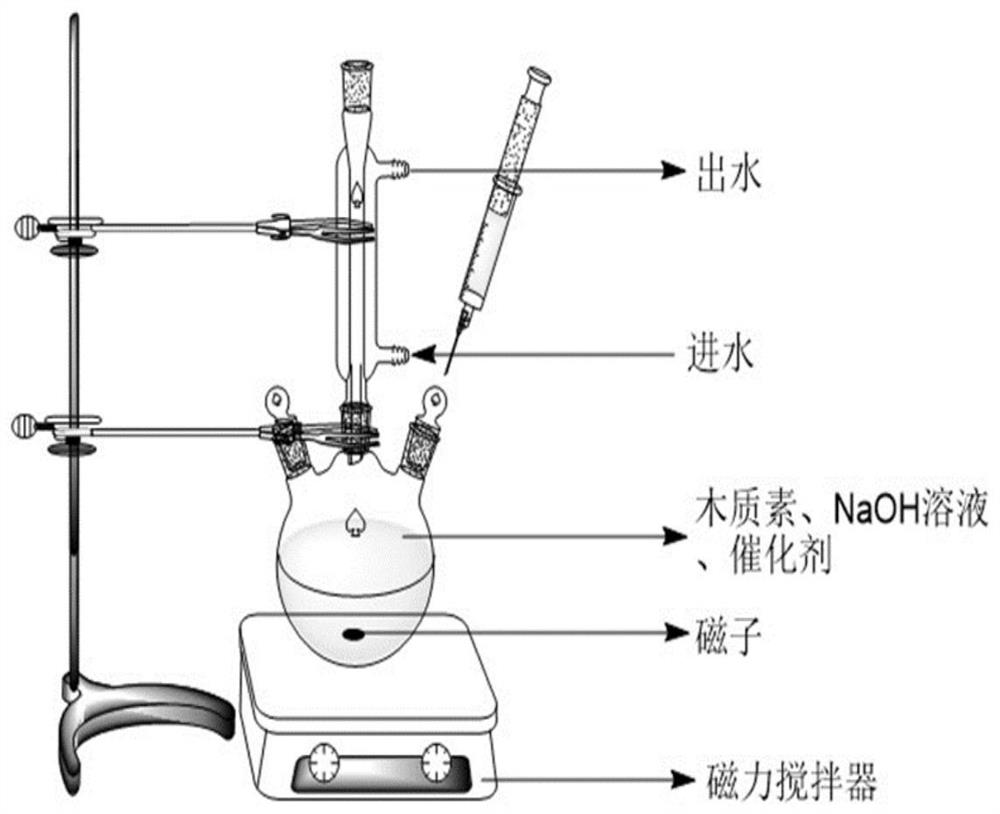

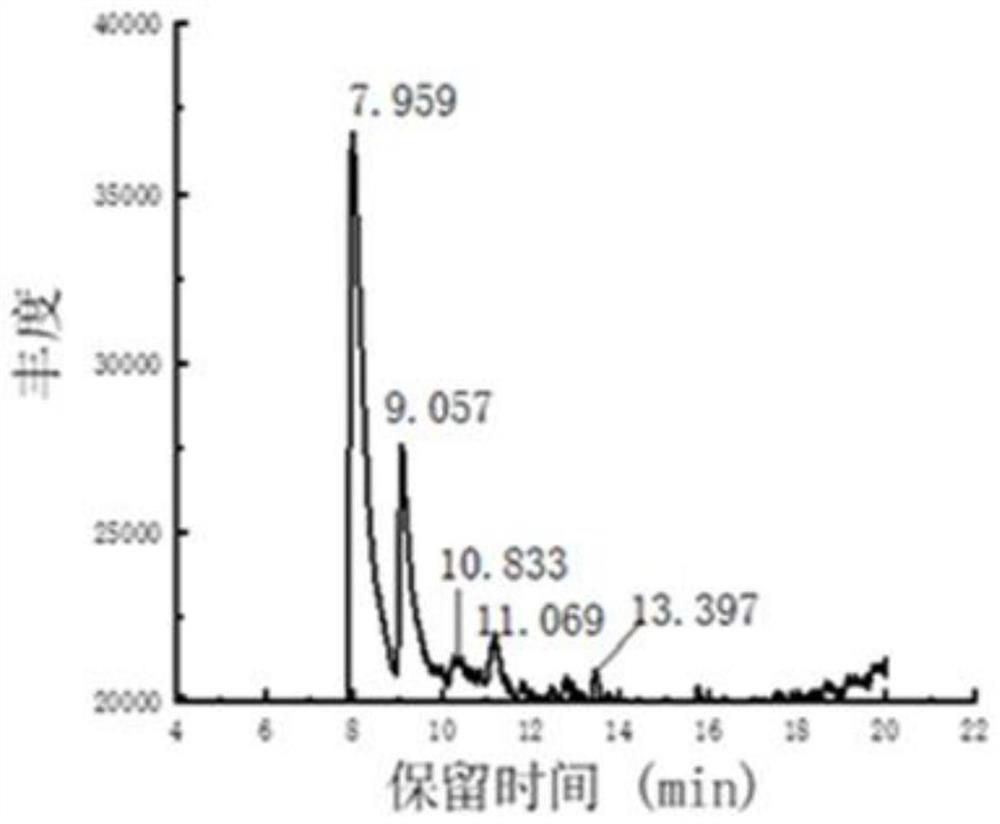

[0022] Add 2g of corn stalk alkali lignin (you can buy it directly, or extract it yourself by corn stalk alkaline process), add 50mL of 1mol / L NaOH solution, add 0.2g of CuSO 4 As a catalyst, it is catalyzed in a three-necked flask of 500ml, a magnetic stirrer is placed in the three-necked flask, a condensation device is installed on the three-necked flask, and the three-necked flask is placed on the magnetic stirrer (see figure 1 ), the number of revolutions is 250rpm, in a 90°C constant temperature water bath with H 2 o 2 Oxidation; use a syringe to add 10mL H 2 o 2 , add 10mL H after 1h 2 o 2 , the oxidation time is 2 hours. After 2 hours, the temperature of the water bath drops to 70°C. Measure an appropriate volume of 0.1mol / LH 2 SO 4 The solution was poured into a three-necked flask, refluxed for 0.5 h, and the pH of the reaction system was adjusted to acidic (pH 1-2). After the reaction, the solution in the three-necked flask was cooled to room temperature, extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com