Wood-plastic reinforced imitation solid wood environment-friendly plate and preparation method thereof

A solid wood imitation, environment-friendly technology, applied in the wood-plastic reinforced imitation solid wood environment-friendly plate and its preparation field, can solve the problems of no flame retardancy, easy breakage, poor mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A wood-plastic reinforced imitation solid wood environment-friendly plate, comprising the following raw materials in parts by weight: 100 parts of modified polystyrene, 30 parts of toughening fiber, 60 parts of wood powder, and 10 parts of calcium carbonate;

[0039] The imitation solid wood environment-friendly board is made by the following steps:

[0040] Step S1: Weigh the above raw materials and mix them uniformly to prepare a mixture;

[0041] Step S2: Put the mixture into the extruder, melt and extrude it into a mold at a temperature of 170° C., cool and form it, and obtain an environmentally friendly board imitating solid wood.

[0042] Described modified polystyrene is made by following steps:

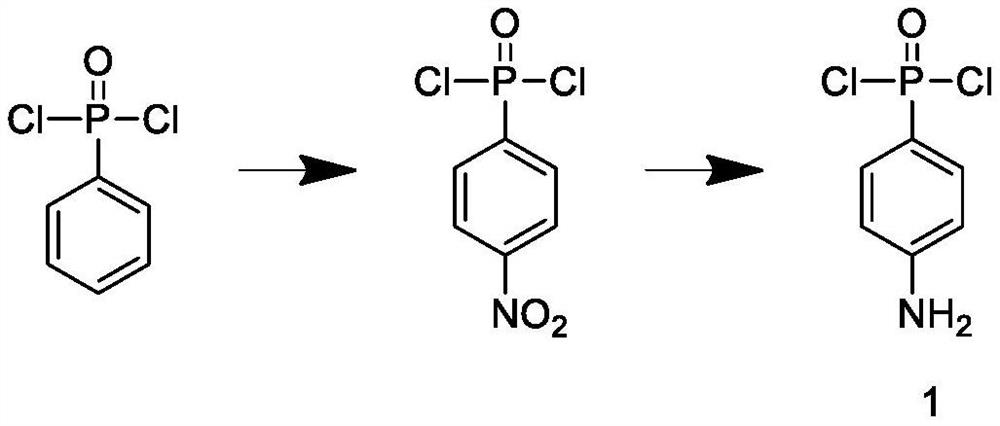

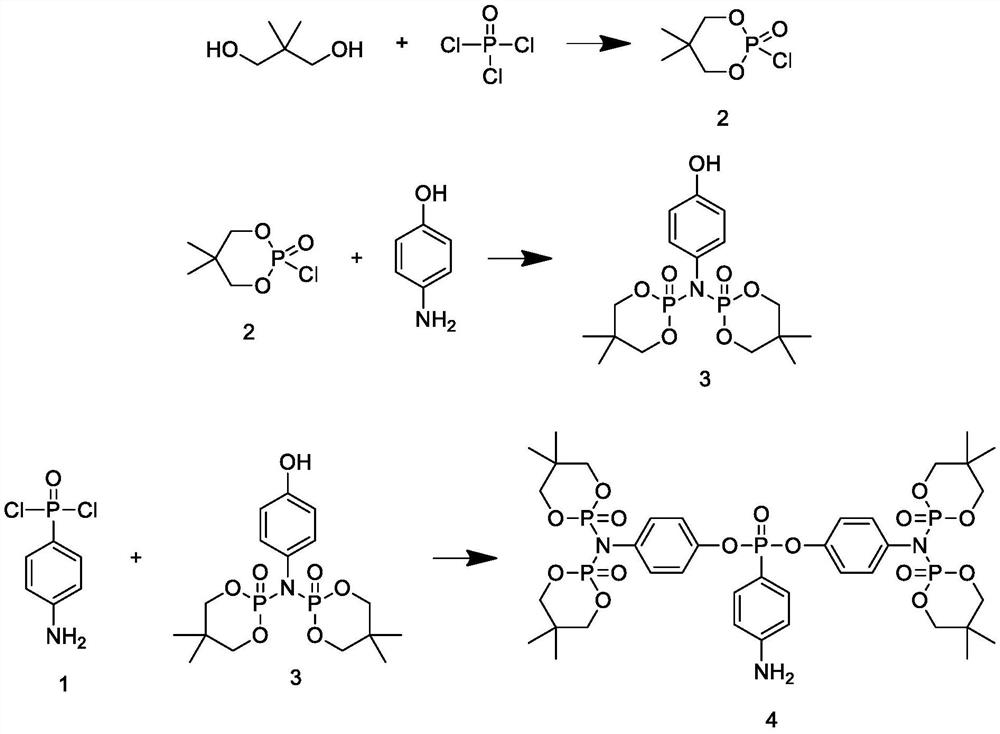

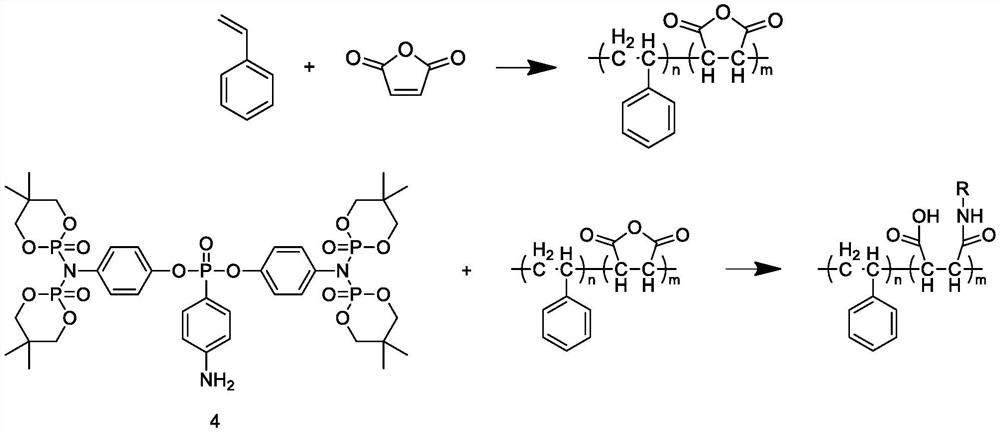

[0043]Step A1: Add phenylphosphoryl dichloride into the reaction kettle, under the condition of rotating speed of 150r / min and temperature of 50℃, stir and add mixed acid dropwise, after the dropwise addition, carry out the reaction for 15min, add iron powder and Acet...

Embodiment 2

[0051] A wood-plastic reinforced imitation solid wood environment-friendly board, comprising the following raw materials in parts by weight: 110 parts of modified polystyrene propylene, 40 parts of toughened fibers, 70 parts of wood powder, and 13 parts of calcium carbonate;

[0052] The imitation solid wood environment-friendly board is made by the following steps:

[0053] Step S1: weigh the above-mentioned raw materials and mix them uniformly to obtain a mixture;

[0054] Step S2: adding the mixed material into the extruder, under the condition of a temperature of 180° C., melt extruding it into a mold, cooling and forming, to obtain a solid wood imitation environment-friendly board.

[0055] Described modified polystyrene propylene is made by the following steps:

[0056] Step A1: Add phenylphosphoryl dichloride into the reaction kettle, under the condition of rotating speed of 180r / min and temperature of 53℃, stir and add mixed acid dropwise, after the dropwise addition,...

Embodiment 3

[0064] A wood-plastic reinforced imitation solid wood environment-friendly board, comprising the following raw materials in parts by weight: 120 parts of modified polystyrene propylene, 50 parts of toughened fibers, 80 parts of wood powder, and 15 parts of calcium carbonate;

[0065] The imitation solid wood environment-friendly board is made by the following steps:

[0066] Step S1: weigh the above-mentioned raw materials and mix them uniformly to obtain a mixture;

[0067] Step S2: adding the mixed material into an extruder, melt extruding it into a mold at a temperature of 190° C., cooling and forming, to obtain a solid wood imitation environmentally friendly board.

[0068] Described modified polystyrene propylene is made by the following steps:

[0069] Step A1: Add phenylphosphoryl dichloride into the reaction kettle, under the condition of rotating speed of 200r / min and temperature of 55℃, stir and add mixed acid dropwise, after the dropwise addition, carry out reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com