Method for characterizing hot crack sensitivity and hot crack sensitive temperature of high-temperature alloy powder

A high-temperature alloy and temperature-sensitive technology, which is applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problems of difficulty in determining the hot cracking tendency of superalloy powder materials and the hot cracking sensitive temperature range, and achieve convenient in-situ observation. , The effect of high measurement accuracy and high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Step 1. Prepare Ni-Co-Cr-W-Mo-Ta-Al-Ti-B-Zr-Nb-C multi-element nickel-based superalloy powder by argon atomization, and pass the prepared metal powder through Mechanical vibrating sieving machine sieves to 63-105μm;

[0045] Step 2. Use the coaxial powder feeding additive manufacturing equipment to screen the superalloy powder material in the sieved particle size section for thermal cracking tendency. The laser power is 700w, and the alloy components that are printed and cracked are selected;

[0046] Step 3. Put the superalloy powder of the selected composition into the stainless steel sheath for degassing, welding and sealing. The diameter of the stainless steel sheath is 10mm, the length is 100mm, and the vacuum degree is -3 Pa;

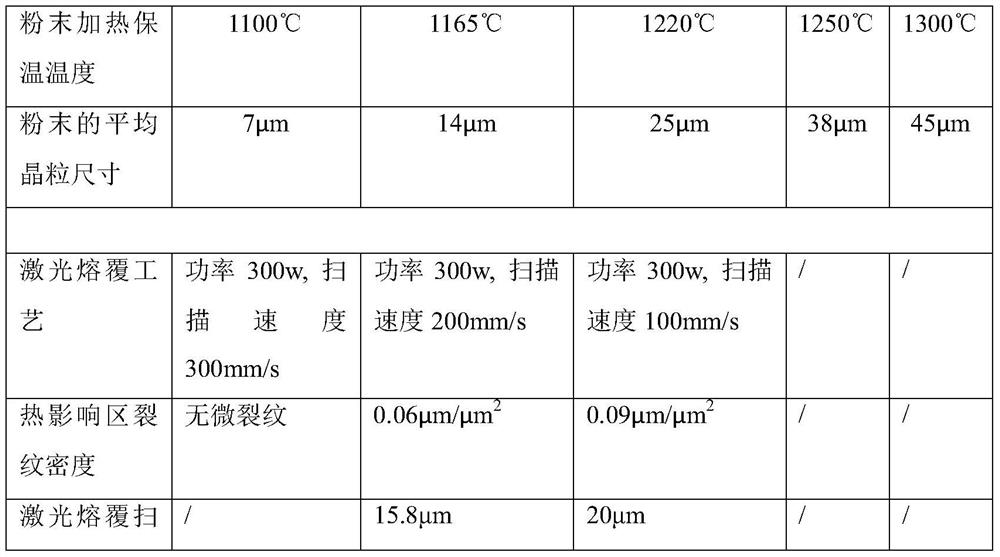

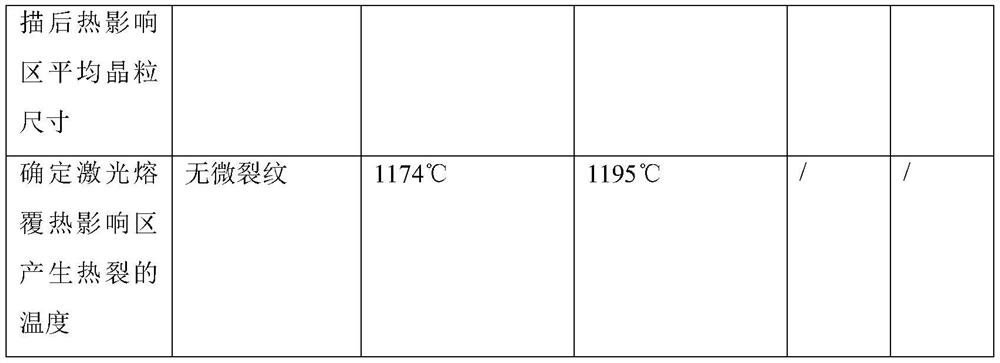

[0047] Step 4. Put the loose powder in the package into the heat treatment furnace and heat it to different temperatures (1100, 1165, 1220, 1250, 1300°C) in the range of 900°C-1500°C, keep it warm for 30s, and then take it out quickly (<2s)...

Embodiment 2

[0054] Step 1. Prepare Ni-Co-Cr-W-Mo-Ta-Al-Ti-B-Zr-Nb-C multi-element nickel-based superalloy powder by argon atomization, and pass the prepared metal powder through Mechanical vibrating sieving machine sieves to 63-105μm;

[0055] Step 2. Use the coaxial powder feeding additive manufacturing equipment to screen the superalloy powder material in the sieved particle size section for thermal cracking tendency. The laser power is 700w, and the alloy components that are printed and cracked are selected;

[0056] Step 3. Put the superalloy powder of the selected composition into the stainless steel sheath for degassing, welding and sealing. The diameter of the stainless steel sheath is 10mm, the length is 100mm, and the vacuum degree is -3 Pa;

[0057] Step 4. Put the loose powder in the package into the heat treatment furnace and heat it to different temperatures (1100, 1165, 1220, 1250, 1300°C) in the range of 900°C-1500°C, keep it warm for 30s, and then take it out quickly (<2s)...

Embodiment 3

[0065] Step 1. Prepare Ni-Co-Cr-W-Mo-Ta-Al-Ti-B-Zr-Nb-C multi-element nickel-based superalloy powder by argon atomization, and pass the prepared metal powder through Mechanical vibrating sieving machine sieves to 63-105μm;

[0066] Step 2. Use the coaxial powder feeding additive manufacturing equipment to screen the superalloy powder material in the sieved particle size section for thermal cracking tendency. The laser power is 700w, and the alloy components that are printed and cracked are selected;

[0067] Step 3. Put the superalloy powder of the selected composition into the stainless steel sheath for degassing, welding and sealing. The diameter of the stainless steel sheath is 10mm, the length is 100mm, and the vacuum degree is -3 Pa;

[0068] Step 4. Put the loose powder in the package into the heat treatment furnace and heat it to different temperatures (1100, 1165, 1220, 1250, 1300°C) in the range of 900°C-1500°C, keep it warm for 30s, and then take it out quickly (<2s)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com