Method for creating and actually measuring axial temperature gradient distribution of electromagnetic gun track

A temperature gradient, electromagnetic gun technology, applied in the direction of thermometers, thermometers, electromagnetic means, etc. using directly sensitive electric/magnetic components, can solve the launch failure, affect the launch efficiency, electromagnetic launch system track thermal stress damage, etc. problem, to achieve the effect of reducing human error and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

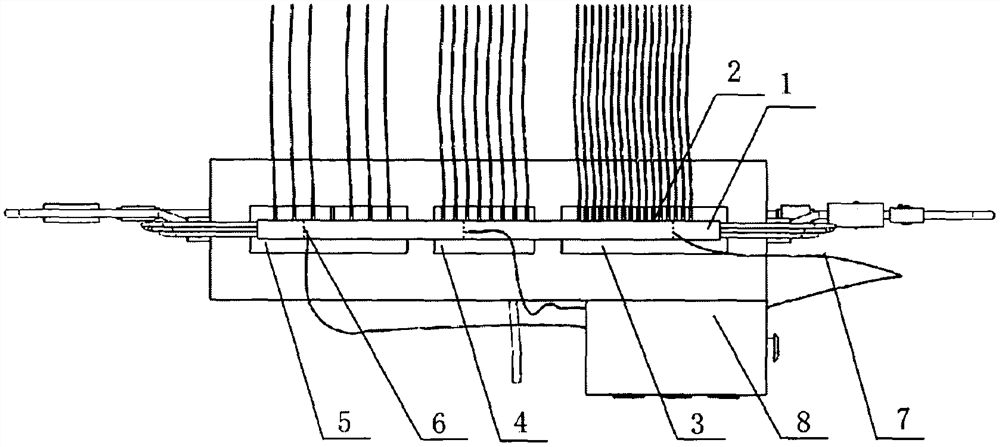

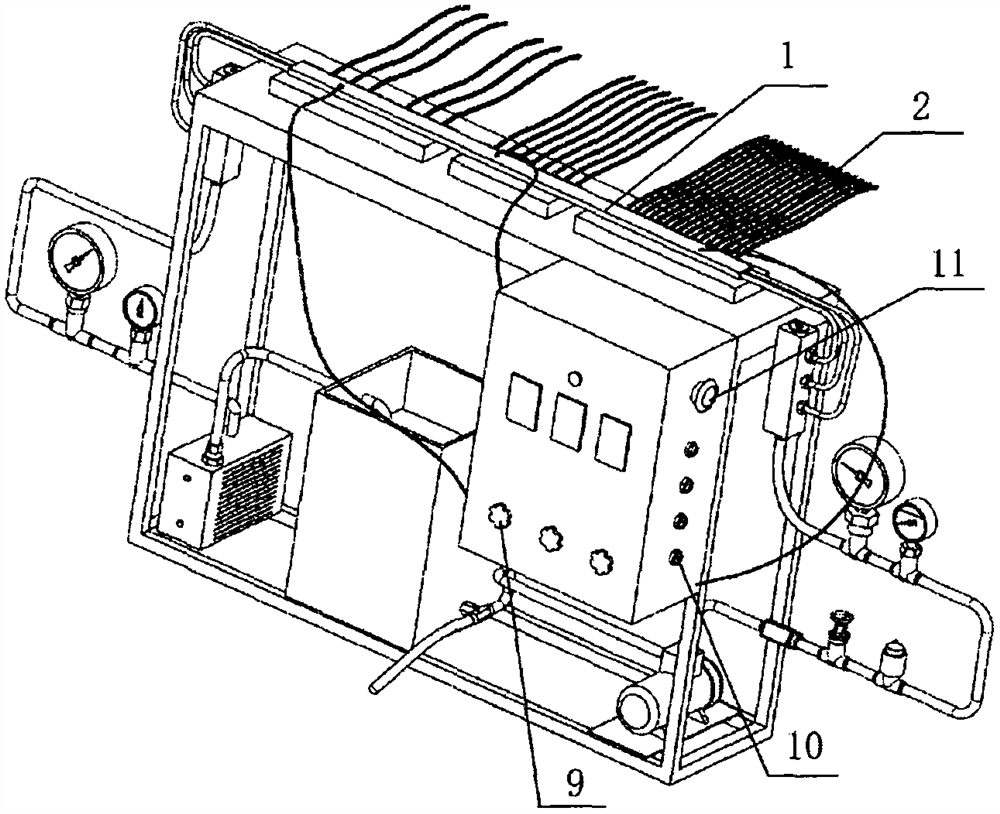

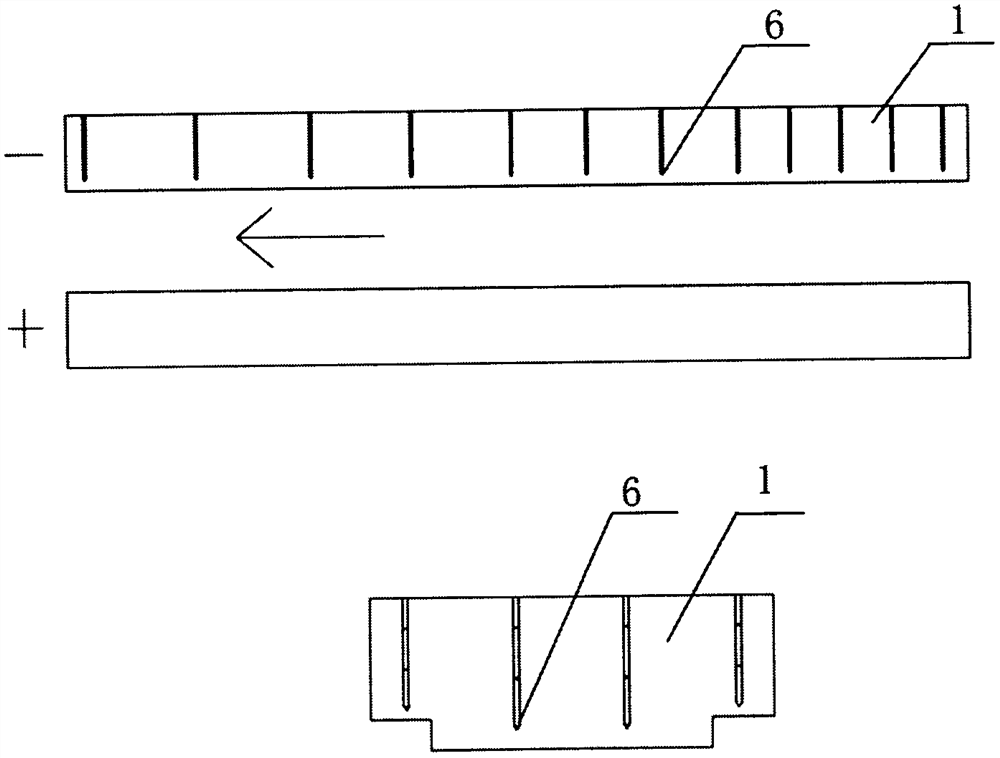

[0021] The present invention will be further described below through the following embodiments in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of this application. It should be understood that the following embodiments are only used to illustrate the present invention, not to limit the present invention.

[0022] The main idea of the embodiment of the present invention is: in the case of no actual missile launch, the electromagnetic copper track is heated by adjusting the quantity and power of the three groups of heating tubes 2, so as to ensure that the temperature of the temperature measuring point on the electromagnetic track reaches the preset value, and the simulated The non-uniform temperature distribution of the track at the moment of launch of the electromagnetic railgun provides an experimental basis for the study of the active cooling and heat transfer characteristics inside the electromagnetic track.

[0023] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com