A Manufacturing Process for Increasing the Handle and Stickiness of Baseball Leather

A production process and leather technology, applied in the field of production process to increase the feel and stickiness of baseball leather, can solve the problems of workers bending over frequently, achieve the effect of reducing the probability of waist diseases, improving the ease of use, and increasing the speed of pitching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A manufacturing process for increasing the feel and stickiness of baseball leather, comprising the following steps:

[0048] Add water and degreasing agent to the drum 1, put the cowhide into it for soaking, take out the cowhide with the drum retrieving device, remove the flesh of the cowhide and drain the liquid in the drum 1;

[0049] Add water, sodium hydrosulfide, sodium sulfide and slaked lime into drum 1, put cowhide into it, soak and expand the cowhide, take out the cowhide with drum retrieving device and drain the liquid in drum 1;

[0050] Depilation of cowhide;

[0051]Add oxalic acid and water into drum 1, put cowhide into it, soak and soften the cowhide, take out the cowhide with drum retrieving device and drain the liquid in drum 1 and drain the liquid in drum 1;

[0052] Add water, formaldehyde, titanium dioxide and special white paste to drum 1, put cowhide into it, after bleaching the cowhide, take out the cowhide with drum retrieving device and drain t...

Embodiment 2

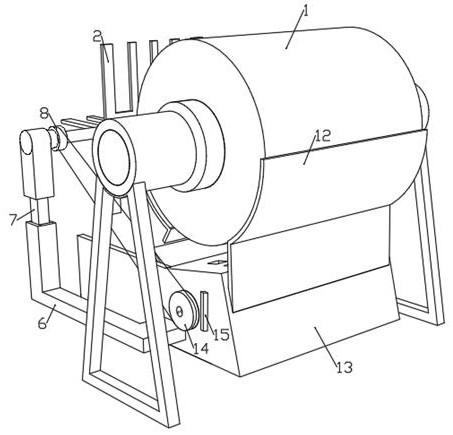

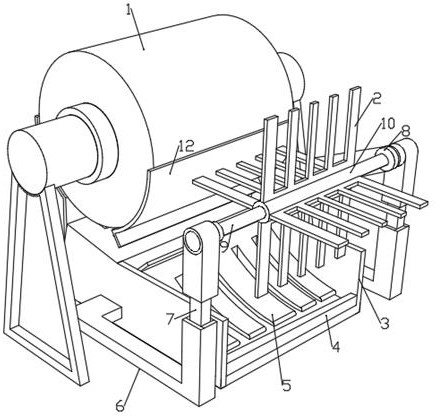

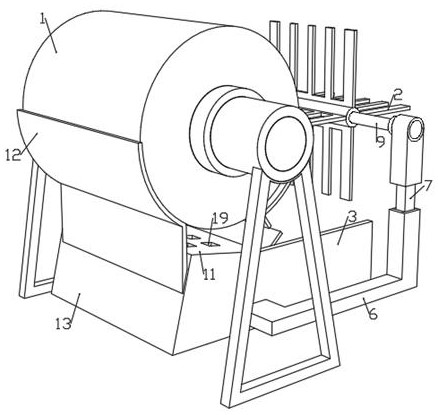

[0062] see Figure 1-4 , the drum retrieving device includes a water flow receiving mechanism and a skin picking mechanism located below the drum 1, and the skin picking mechanism is located on one side of the water flow receiving mechanism;

[0063] The water flow receiving mechanism includes a base 13, a second pulley 14 and a water flow vane 16. The base 13 is located directly below the outlet of the drum 1. There is a space in the base 13, and a central shaft is connected to the rotation in the space, and the circumference of the central shaft is uniform. A plurality of water flow blades 16 are arranged, and a water inlet surface 11 is arranged obliquely above the base 13. A plurality of water inlets 19 are provided on the water inlet surface 11. The water inlets 19 are located on one side of the central axis, and the central axis protrudes from the base 13 One end is fixedly connected with a second pulley 14, and the second pulley 14 is connected with a skin picking mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com