Device for preparing precipitated calcium carbonate by adopting supercritical carbon dioxide

A technology for precipitating calcium carbonate and carbon dioxide, applied in calcium carbonate/strontium/barium, nanotechnology for materials and surface science, inorganic chemistry, etc., can solve problems such as batch quality variance, unsatisfactory dispersion and stability , to achieve the effects of small particle size range, convenient maintenance and daily maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

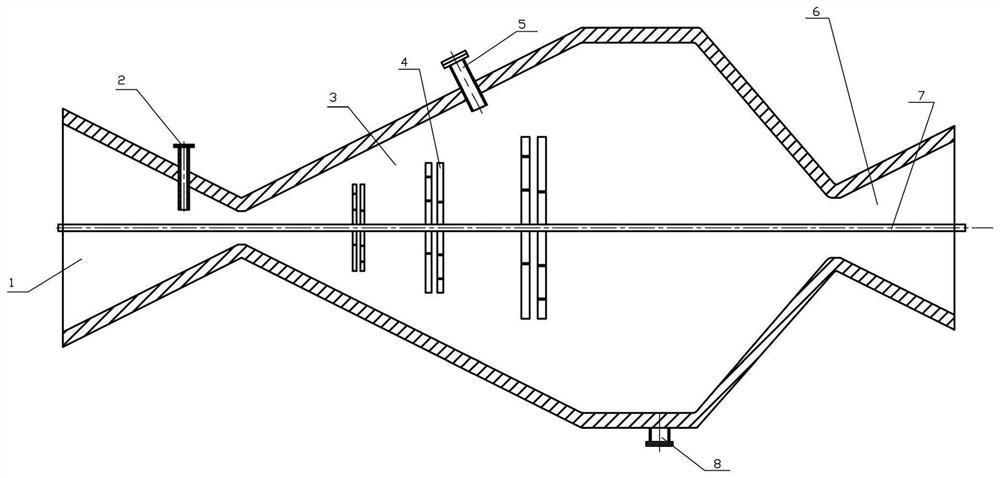

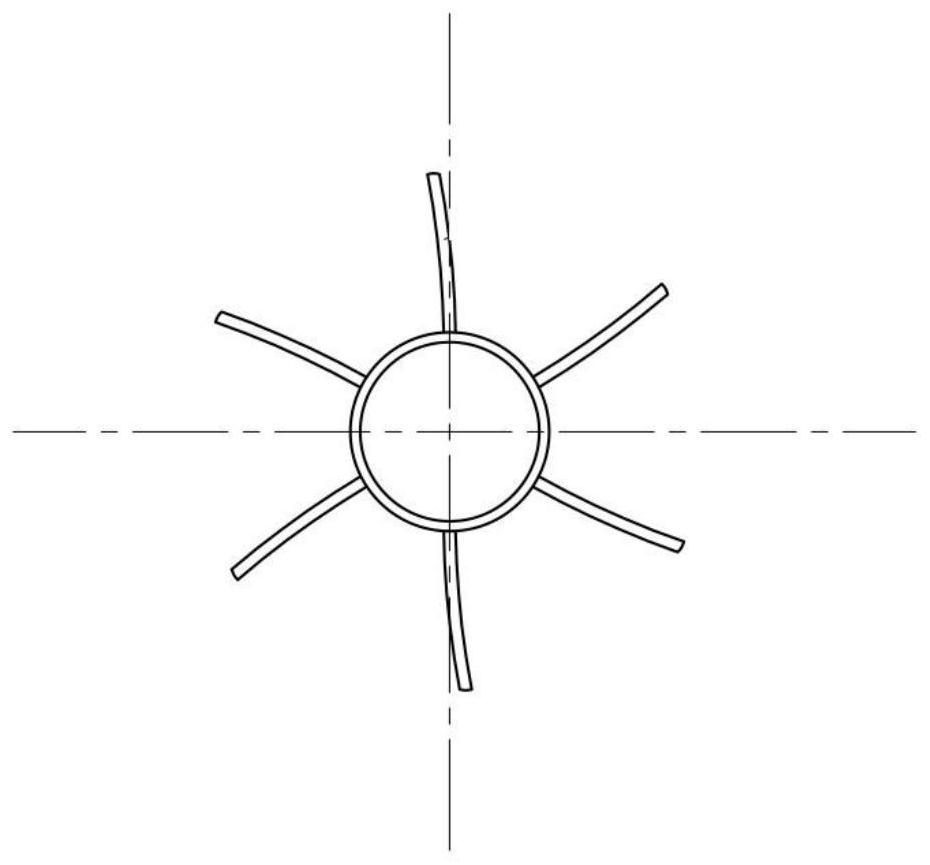

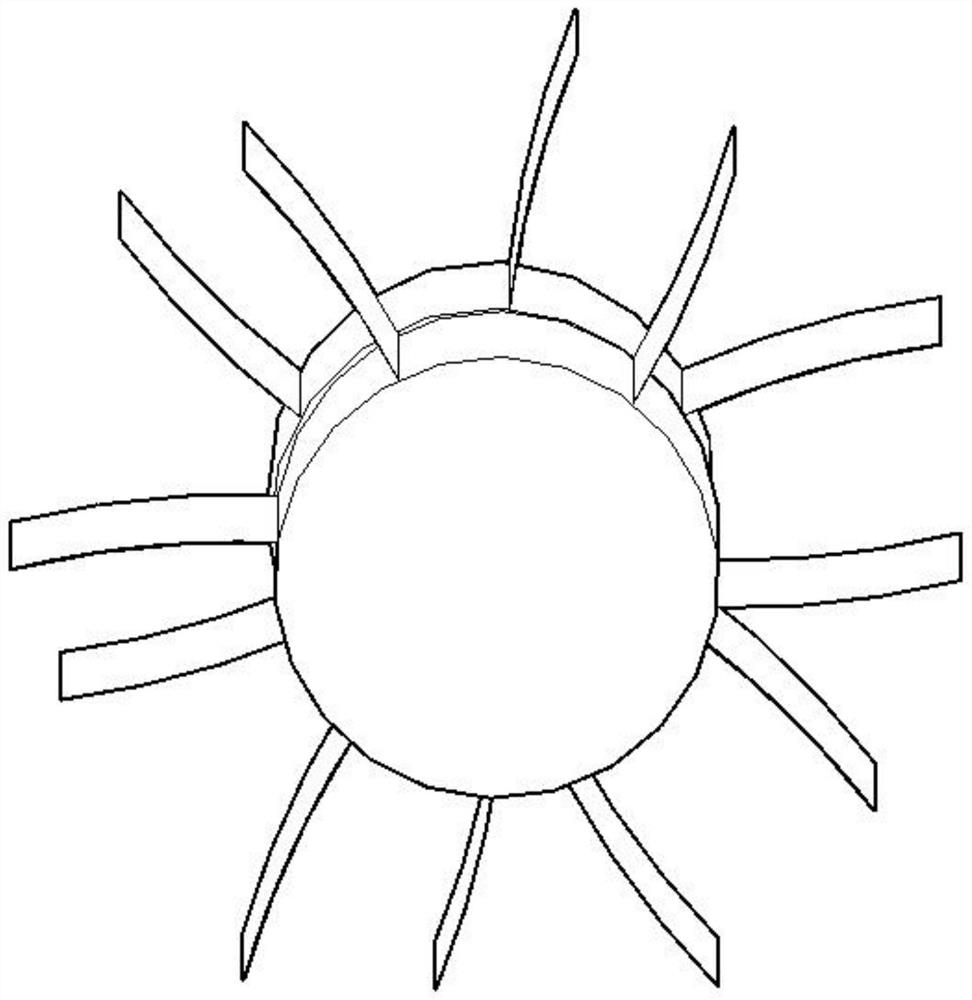

[0043] Such as figure 1 As shown, the present embodiment is the use of supercritical CO described in the present invention 2 An example of a multi-phase volute continuous carbonization device for PCC, the components include a fine slurry inlet 1, a supercritical CO 2 Input nozzle 2, carbonization reactor 3, forward and reverse paddle turbine combination 4, crystal form control agent inlet 5, Laval nozzle 6, central shaft 7, maintenance manhole 8. The specific position and connection relationship of the components are as follows:

[0044] The supercritical CO 2The input nozzle 2 is arranged on the fine pulp inlet 1, and the fine pulp inlet 1 is connected to the inlet of the carbonization reactor 3, and the fine pulp inlet 1 is a horn pipe that gradually shrinks, and the feed port of the carbonization reactor 3 is connected to the inlet of the fine pulp inlet. Small opening, the discharge port of the carbonization reactor is connected to the Laval nozzle. The carbonization re...

Embodiment 2

[0049] Present embodiment is the example of the method for preparing PCC by the device that adopts supercritical carbon dioxide to prepare precipitated calcium carbonate, comprises the following steps:

[0050] (1) The saturated calcium hydroxide slurry is fed in under pressure from the fine pulp inlet, so that the flow rate of the saturated calcium hydroxide slurry is Mach 1.

[0051] (2) From supercritical CO 2 The input nozzle feeds supercritical CO 2 ; and accelerate to Mach 1.5.

[0052] (3) Combine saturated calcium hydroxide slurry and supercritical CO 2 Accelerate the pressure into the carbonization reactor through the gradually reduced variable diameter pipe;

[0053] (4) The saturated calcium hydroxide slurry and the supercritical CO 2 Stir while adding the crystal form control agent through the crystal form control agent inlet;

[0054] (5) The calcium carbonate slurry generated by the reaction is discharged from the Wahl spout, and the discharge is precipitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com