Attapulgite-based composite multifunctional powder as well as preparation method and application thereof in PVC (polyvinyl chloride) composite material

A technology of attapulgite and composite materials, applied in PVC composite materials, in the field of attapulgite-based composite multifunctional powders, can solve problems such as smoke suppression and absence of polymer materials, and achieve simple preparation process and improved Smoke suppression and flame retardant properties, the effect of good smoke suppression and flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

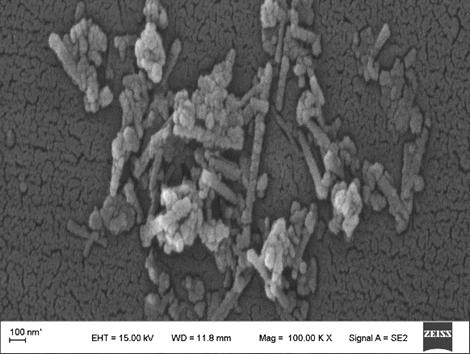

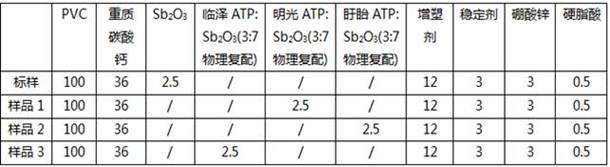

[0035] Attapulgite attapulgite from Mingguang in Anhui, Linze in Gansu and Xuyi in Jiangsu were respectively selected, the attapulgite raw ores from different origins were crushed, ball milled and sieved, and 200-500 mesh powder was obtained. Physically mix attapulgite from different origins with commercially available antimony trioxide in a weight ratio of 3:7, ultrafinely pulverize to above 2500 mesh, take 2.5 parts, and banbury and blend with raw materials such as PVC according to the formula in Table 1 ( 190°C), vulcanization and pressing (200°C) to make PVC composite materials. The flame retardant and smoke suppression properties and mechanical properties of the tested PVC composites are shown in Table 2.

[0036] Table 1 PVC composite formula (parts by weight)

[0037]

[0038] Table 2 Properties of PVC composites

[0039]

[0040] From the test results in Table 2, it can be seen that the attapulgite in Xuyi, Jiangsu Province has the best performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com