Hierarchical pore monolithic molecular sieve catalyst and preparation method and application thereof

A molecular sieve and catalyst technology, applied in the field of integral molecular sieve catalyst and its preparation, can solve problems such as poor firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

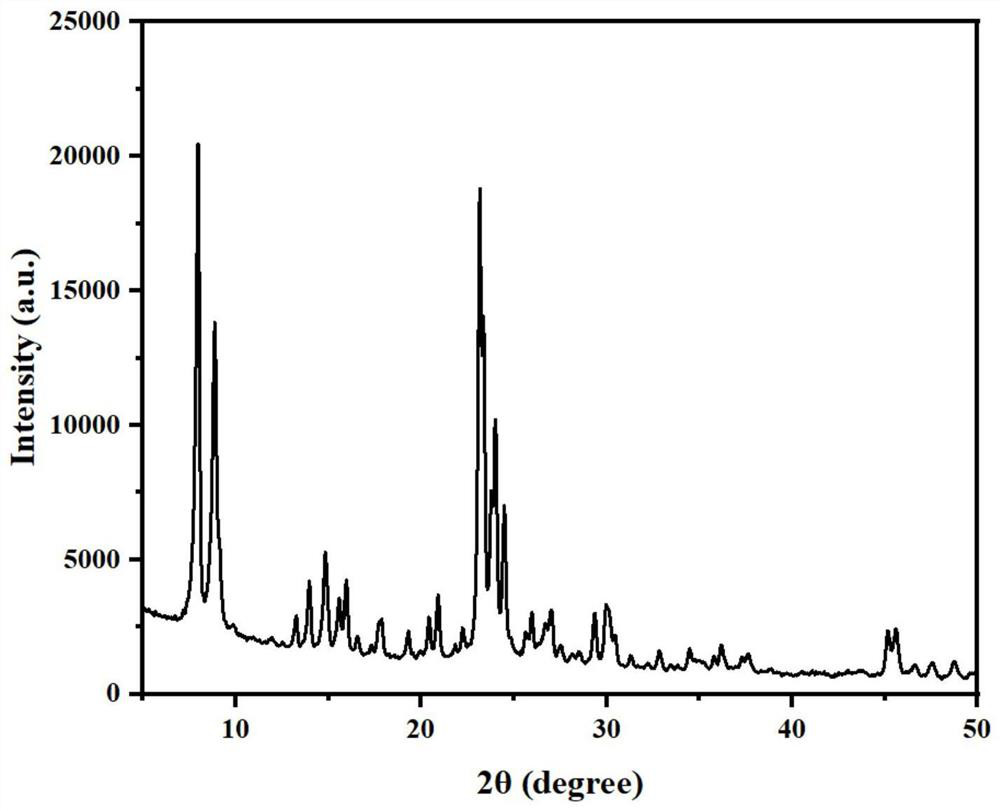

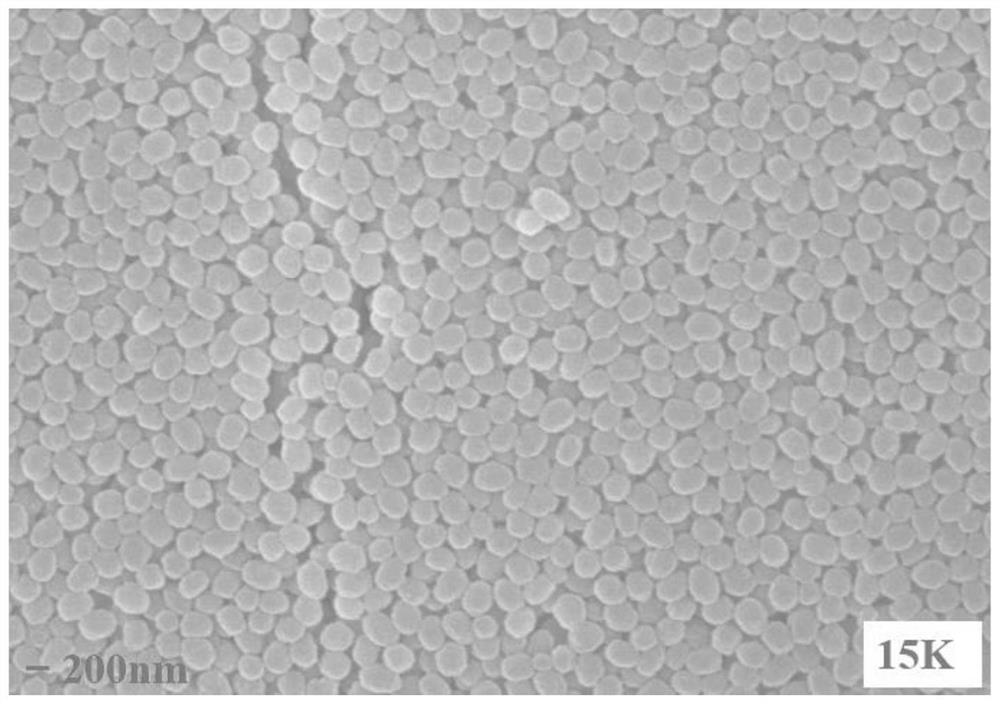

[0073] Add 3.31g of TPAOH aqueous solution (0.3molTPAOH, Wokai, 25%w / w aq.Soln) into 12.00g of water, then add 2.36g of TEOS (1mol, Aladdin, 98wt%), then dropwise add 2mL containing 0.06g of TBOT (0.015mol, Sinopharm, 98wt%) IPA (Shanghai test, 99.7wt%) solution to obtain 20mL premixed solution, heated and stirred at 85°C for 3h, then added 0.01gCTAB (2.7×10 -5 mol, Aladdin, 99wt%) stirred and transferred to a crystallization kettle lined with polytetrafluoroethylene, and then the pretreated cordierite carrier was immersed in the precursor solution for 6h, at a reaction temperature of 110°C and an autogenous pressure Under static crystallization for 36h. After the hydrothermal reaction is completed, the reaction solution is cooled, filtered and washed to obtain a crystalline product. The obtained crystals were dried at 110°C overnight, and then calcined in a muffle furnace at 550°C for 6 hours to obtain the product TS-MFI-1. The obtained product was determined by gravimetric...

Embodiment 2

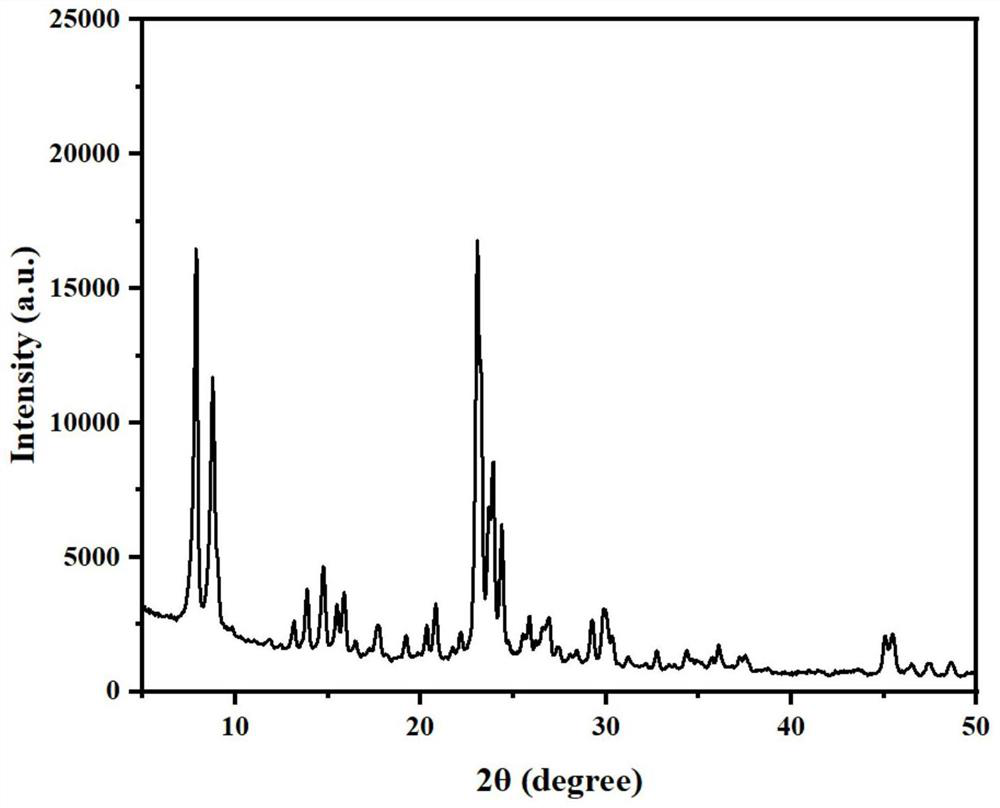

[0075]Add 3.31g of TPAOH aqueous solution (0.3mol, Wokai, 25%w / w aq.Soln) into 12.00g of water to dissolve, then add 2.36g of TEOS (1mol, Aladdin, 98wt%), then add dropwise 2mL containing 0.06g of TBOT (0.015mol, Sinopharm, 98wt%) IPA (Shanghai test, 99.7wt%) solution to obtain 20mL premixed solution, heated and stirred at 85°C for 3h, then added 0.02g polyether F127 (1.5×10 -6 mol, Wokai, 98wt%) stirred and then transferred to a crystallization kettle with polytetrafluoroethylene lining, and then immersed the pretreated cordierite carrier in the precursor solution for 6h, at 140 ° C reaction temperature and autogenous pressure Under static crystallization for 36h. After the hydrothermal reaction is completed, the reaction solution is cooled, filtered and washed to obtain a crystalline product. The obtained crystals were dried at 110° C. overnight, and then calcined in a muffle furnace at 550° C. for 6 hours to obtain the product TS-MFI-2. The obtained product was determined...

Embodiment 3

[0077] Add 3.31g of TPAOH aqueous solution (0.3mol, Wokai, 25%w / w aq.Soln) into 12.00g of water to dissolve, then add 2.36g of TEOS (1mol, Aladdin, 98wt%), then add dropwise 2mL containing 0.06g TBOT (0.015mol, Sinopharm, 98wt%) IPA (Shanghai test, 99.7wt%) solution to obtain 20mL premixed solution, heated and stirred at 85°C for 3h, then added 0.01gCTAB (2.7×10 -5 mol, Aladdin, 99wt%) stirred and transferred to a crystallization kettle lined with polytetrafluoroethylene, and then the pretreated cordierite carrier was immersed in the precursor solution for 6h, at 140 ° C reaction temperature and autogenous pressure Under static crystallization for 36h. After the hydrothermal reaction is completed, the reaction solution is cooled, filtered and washed to obtain a crystalline product. The obtained crystals were dried at 110° C. overnight, and then calcined in a muffle furnace at 550° C. for 6 hours to obtain the product TS-MFI-3. The obtained product was determined by gravimetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com