A kind of preparation method of the hollow microsphere material that is used for lithium-sulfur battery cathode

A technology of hollow microspheres and lithium-sulfur batteries, applied in nanotechnology for materials and surface science, lithium batteries, battery electrodes, etc., can solve problems such as uneven distribution, difficult growth of shell materials, and uneven size. To achieve the effect of improving reaction kinetics, realizing cycle stability, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

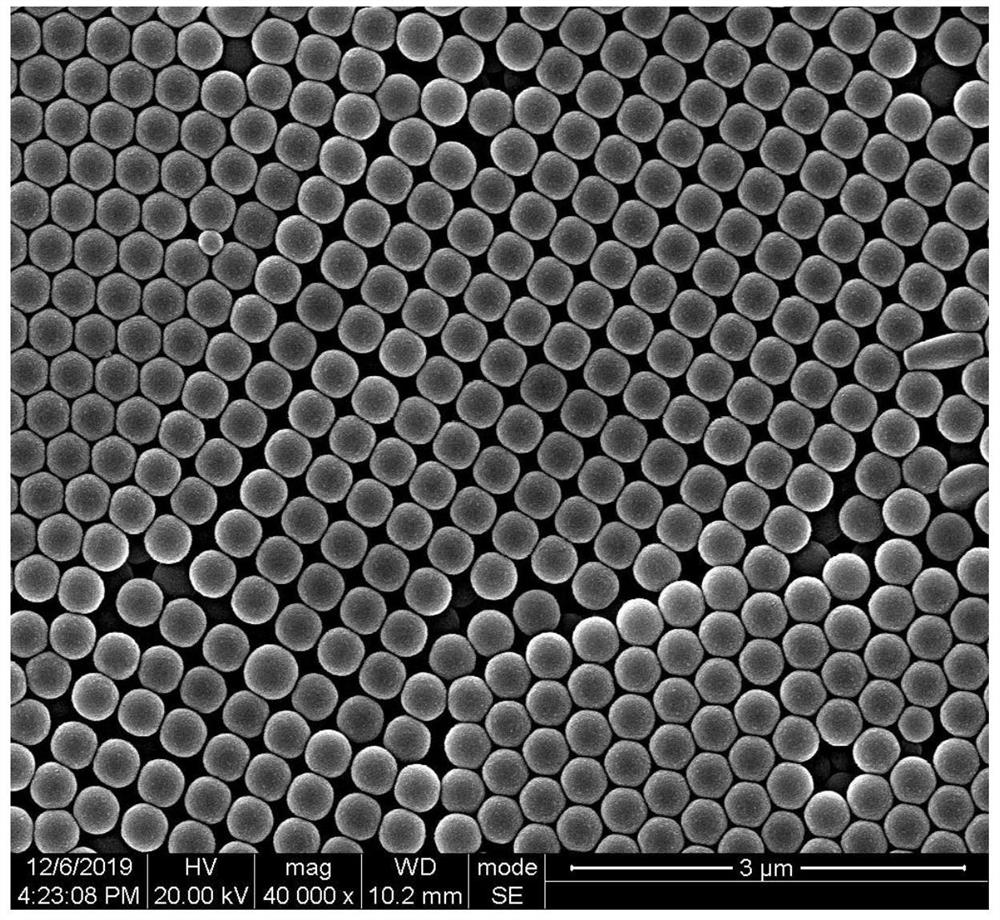

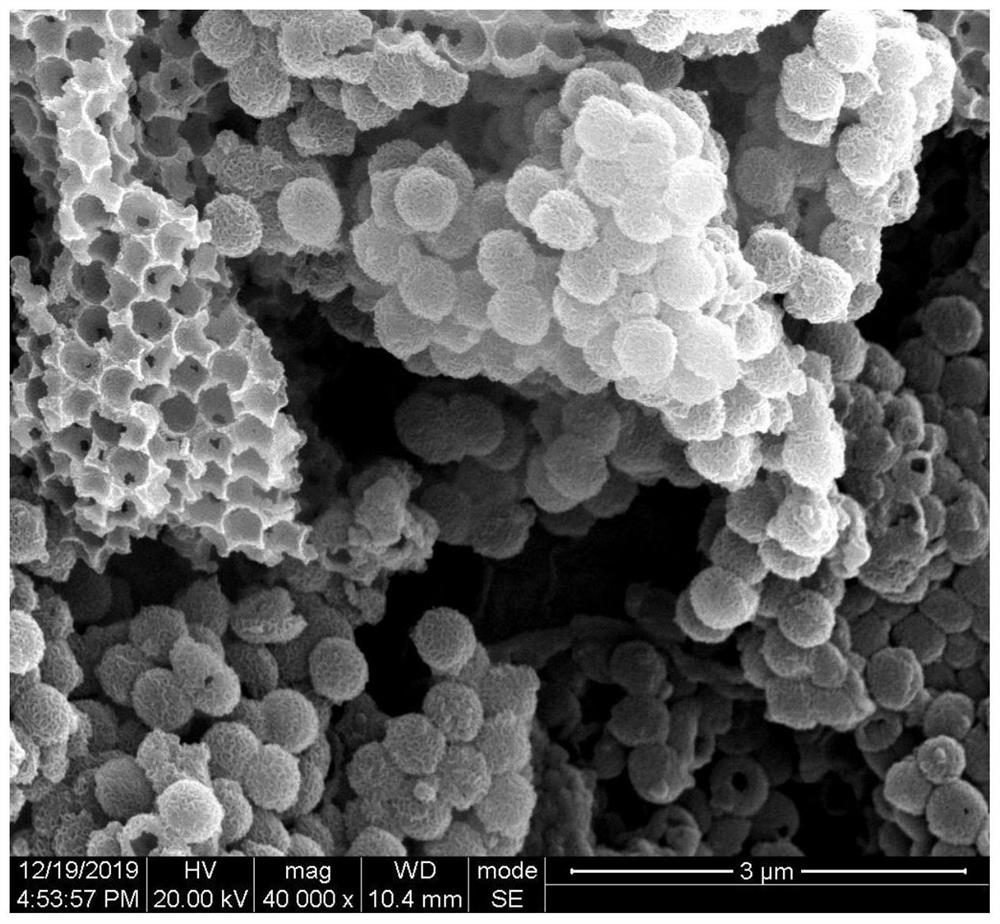

[0039] A method for preparing a hollow microsphere material for a positive electrode of a lithium-sulfur battery, comprising the steps of:

[0040] Step 1. Dissolve 0.5g-1.5g polyvinylpyrrolidone in 500ml-1000ml water and stir in a three-necked flask;

[0041] Step 2, taking 50g-100g of styrene and adding it to the solution treated in step 1, stirring, and feeding nitrogen gas at the same time to form an emulsion;

[0042] Step 3, the emulsion is heated to 50°C-70°C in an oil bath, and 5ml-15ml of aqueous solution is added to the emulsion, which contains 0.5g-1.5g of 2,2-azobis(2-methylpropyl Imido) dihydrochloride;

[0043] Step 4, blow nitrogen, react at a temperature of 50°C-100°C for 24h, and obtain precipitate A;

[0044] Step 5, washing the precipitate A produced in step 4 with alcohol and then freeze-drying to obtain PS pellets;

[0045] Step 6. Dissolve 2-3g PS pellets in 20-30ml water and stir evenly to form latex;

[0046] Step 7, 0.5-1g cetyltrimethylammonium brom...

Embodiment 2

[0056] Step 1. Dissolve 0.5g of polyvinylpyrrolidone in 500ml of water and stir in a three-necked flask;

[0057] Step 2, 50g of styrene is added to the solution treated in step 1, stirred, and nitrogen gas is introduced at the same time to form an emulsion;

[0058] Step 3, the emulsion is heated to 50 degrees by an oil bath, and 5ml of an aqueous solution is added to the emulsion, and the aqueous solution contains 0.5g of 2,2-azobis(2-methylpropylimidium) dihydrochloride;

[0059] Step 4, feed nitrogen, react at 100 degrees for 24 hours, and obtain precipitate A;

[0060] Step 5, washing the precipitate A produced in step 4 with alcohol and then freeze-drying to obtain PS pellets;

[0061] Step 6. Dissolve 2.5g PS pellets in 20% water and stir evenly to form latex;

[0062] Step 7, 0.5g of cetyltrimethylammonium bromide (CTAB), 5 grams of ethanol, and 2 grams of ammonia were dissolved in 8ml of water;

[0063] Step 8, adding the latex solution obtained in step 6 dropwise ...

Embodiment 3

[0072] Step 1. Dissolve 1g of polyvinylpyrrolidone in 500ml of water and stir in a three-necked flask;

[0073] Step 2, 50g of styrene is added to the solution treated in step 1, stirred, and nitrogen gas is introduced at the same time to form an emulsion;

[0074] Step 3, the emulsion is heated to 50 degrees by an oil bath, and 5ml of an aqueous solution is added to the emulsion, and the aqueous solution contains 0.5g of 2,2-azobis(2-methylpropylimidium) dihydrochloride;

[0075] Step 4, under nitrogen, react at 100 degrees for 24 hours to obtain precipitate A;

[0076] Step 5, washing the precipitate A produced in step 4 with alcohol and then freeze-drying to obtain PS pellets;

[0077] Step 6. Dissolve 2.2g PS pellets in 20% water and stir evenly to form latex;

[0078] Step 7, 0.5g of cetyltrimethylammonium bromide (CTAB), 5 grams of ethanol, and 2 grams of ammonia were dissolved in 8ml of water;

[0079] Step 8, adding the latex solution obtained in step 6 dropwise int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com