Method for synthesizing high-purity calamine via hydrothermal process

A technology of hemimorphite and hydrothermal method, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of low purity of hemimorphite zinc silicate, low purity, difficult separation and extraction, etc., to achieve convenient Large-scale production, mild reaction conditions, simple reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 50g of zinc metasilicate according to the liquid-solid ratio of 12mL / g, put it into a 1L reactor, add 600mL of distilled water into the reactor, seal the reactor, feed industrial oxygen, at a constant speed of 600rpm and a constant pressure of 1.0MPa, respectively The set temperature is 140-220°C. When the temperature rises to the set temperature, the timing starts. At this temperature, the hydrothermal reaction is carried out for 3 hours; after cooling down to 70°C through the water cooling tube, the liquid-solid separation of the obtained substance is carried out, and then the liquid is separated at 65°C. Dry under conditioned conditions for 10 hours.

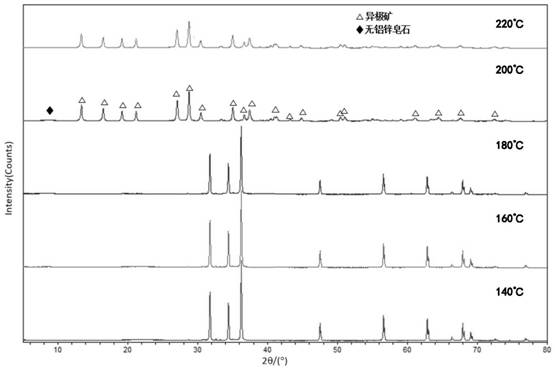

[0027] figure 1 XRD powder diffraction patterns of samples obtained at different temperatures. Depend on figure 1 It can be seen that when the reaction temperature is lower than 200°C, with the increase of the reaction temperature, the XRD pattern of the obtained sample has no obvious change, which is basically...

Embodiment 2

[0029] Weigh 50g of zinc metasilicate according to the liquid-solid ratio of 12mL / g, put it into a 1L reactor, add 600mL of distilled water into the reactor, seal the reactor, feed industrial oxygen, at a constant speed of 600rpm and a constant pressure of 1.0MPa, the temperature Start timing when it rises to 200°C, and set the hydrothermal reaction at this temperature for 1-3 hours; after cooling down to 70°C through the water cooling tube, the liquid-solid separation of the obtained substance is carried out, and then dried at 65°C for 10 Hour.

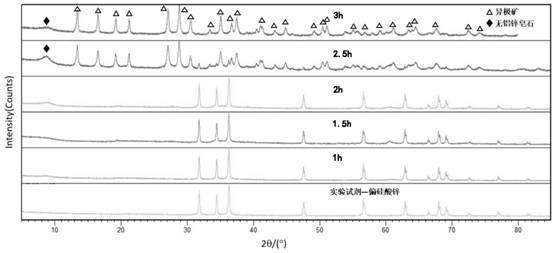

[0030] figure 2 It is the XRD powder diffraction pattern of samples obtained under different reaction times at 200°C. Depend on figure 2 It can be seen that when the hydrothermal reaction temperature is 200°C, as the reaction time is extended to 2h, the XRD pattern of the synthesized product does not change significantly, which is basically consistent with the XRD pattern of the raw material zinc metasilicate; continue to extend ...

Embodiment 3

[0032] Weigh 50g of zinc metasilicate according to the liquid-solid ratio of 12mL / g, put it into a 1L reactor, add 600mL of distilled water into the reactor, seal the reactor, feed industrial oxygen, at a constant speed of 600rpm and a constant pressure of 1.0MPa, the temperature Start timing when the temperature rises to 220°C, and set the hydrothermal reaction at this temperature for 1-3 hours; after cooling down to 70°C through the water cooling tube, the liquid-solid separation of the obtained substance is carried out, and then dried at 65°C for 10 Hour.

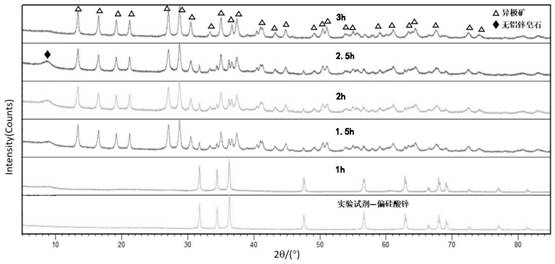

[0033] image 3 It is the XRD powder diffraction pattern of samples obtained under different reaction times at 220°C. Depend on image 3 It can be seen that under the condition of hydrothermal reaction temperature of 220 ° C, as the reaction time is extended to 1 h, the XRD pattern of the obtained sample has no obvious change, which is basically consistent with the XRD pattern of the raw material zinc metasilicate; whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com