Preparation method and preparation system of battery-grade rare earth electrolyte

A preparation system and electrolyte technology, which is applied in the field of preparation of battery-grade rare earth electrolytes, can solve problems such as incomplete fluorination, and achieve the effects of improving product competitiveness, reducing energy consumption, and increasing the rate of qualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

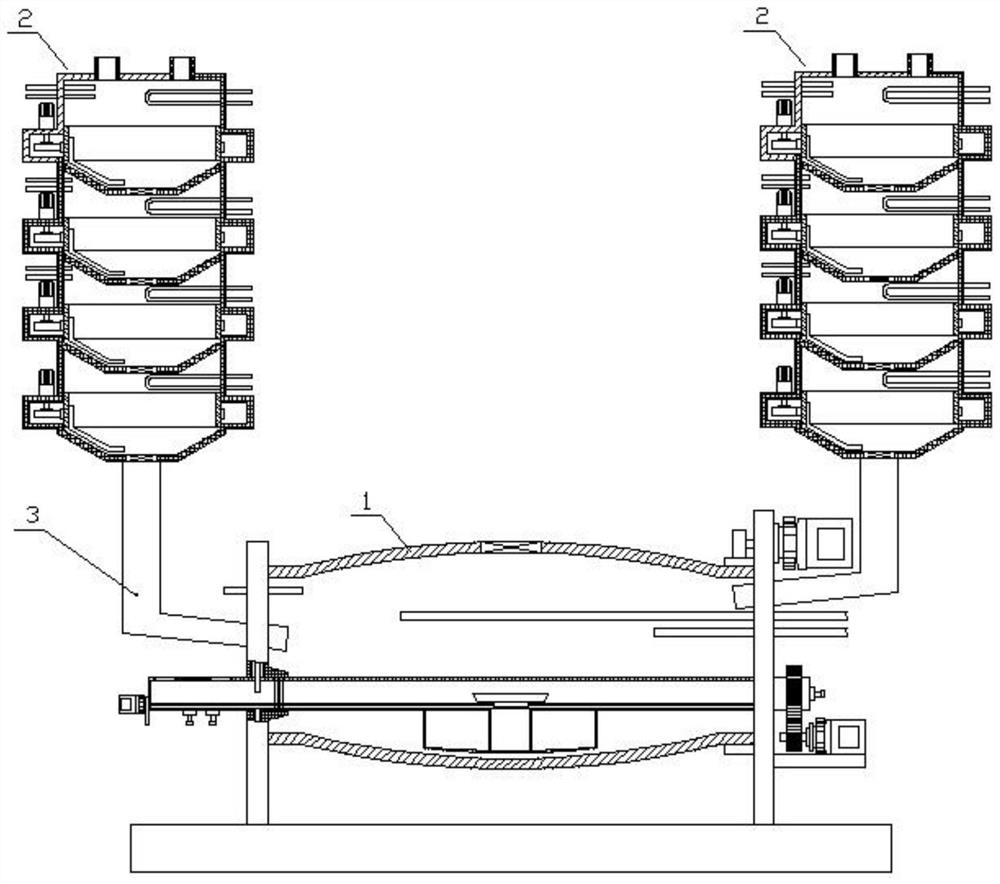

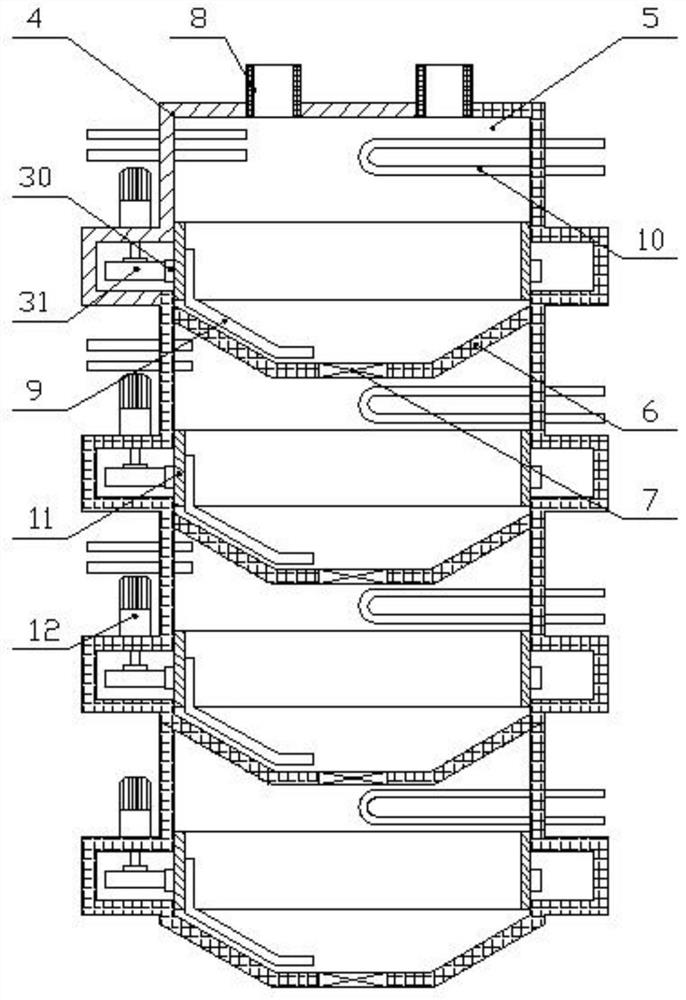

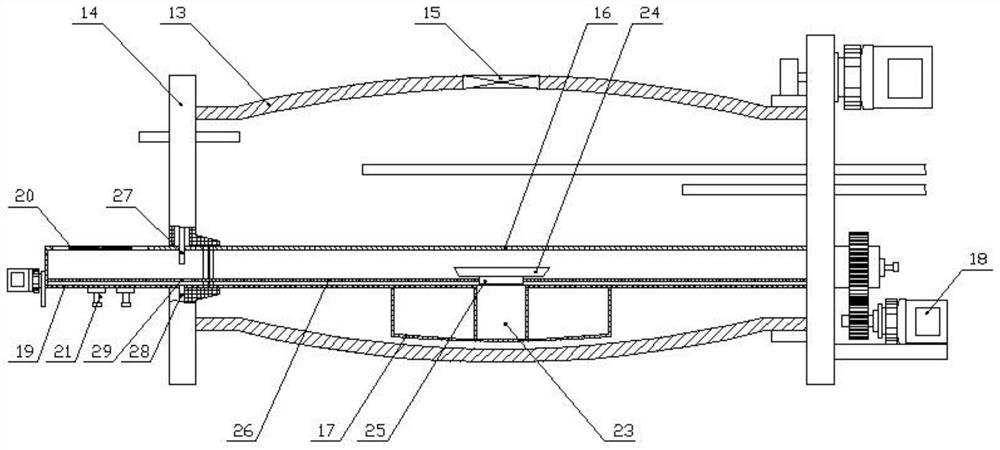

[0026] Example 1, such as Figure 1-2 As shown, the specific structure of the present invention is a preparation system for battery-grade rare earth electrolytes, which includes a main fluorination furnace 1 and a raw material fluorination furnace 2, and the discharge port of the raw material fluorination furnace 2 is connected to the main fluorination furnace through a connecting pipe 3. The feed end of the fluorination furnace 1 is connected. In this implementation, there are two raw material fluorination furnaces 2, which are respectively used for the fluorination of lanthanum cerium carbonate and the fluorination and purification of lithium fluoride and potassium fluoride. For the convenience of introducing this application According to the technical scheme, the two raw material fluorination furnaces 2 in this implementation are respectively named No. 1 raw material fluorination furnace and No. 2 raw material fluorination furnace for convenience of description. According to...

Embodiment 2

[0028] Example 2, such as figure 2 As shown, the other structures of this embodiment are the same as those of Embodiment 1, but in order to flexibly adjust the temperature in the reaction chamber 5, a pipeline 10 is arranged in the reaction chamber 5, and the water inlet end and the water outlet end of the pipeline 10 extend out of the furnace. The body is connected with an oil temperature machine or a water temperature machine, etc., and the temperature in the reaction chamber 5 is adjusted by adjusting the temperature of the liquid in the pipeline 10 .

Embodiment 3

[0029] Example 3, such as figure 2As shown, the other structures of this embodiment are the same as those of Embodiment 1, but in the embodiment, in order to facilitate the rotation of the stirring part 9 in the reaction chamber 5 in the middle of the furnace body 4, and reduce the heat exchange between two adjacent reaction chambers 5, the The stirring part 9 is arranged on the rotating ring 11, the outer wall of the rotating ring 11 is rotatably matched with the inner wall of the furnace body 4, and the outer wall of the rotating ring 11 is provided with a transmission gear 30 concentric with it, and the transmission gear 30 is stirred with the raw material The driving gear 31 on the output shaft of the motor 12 is meshed, and the raw material stirring motor 12 is arranged on the outside of the body of furnace 4, and the output shaft passes through the shaft seal and extends into the body of furnace 4; , chain, etc. for transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com