Concrete repair material and preparation method thereof

A repair material and concrete technology, applied in the field of concrete repair materials, can solve the problems of long curing time, low strength, easy shrinkage, etc., and achieve the effect of good durability, uniform thickness, and dense slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

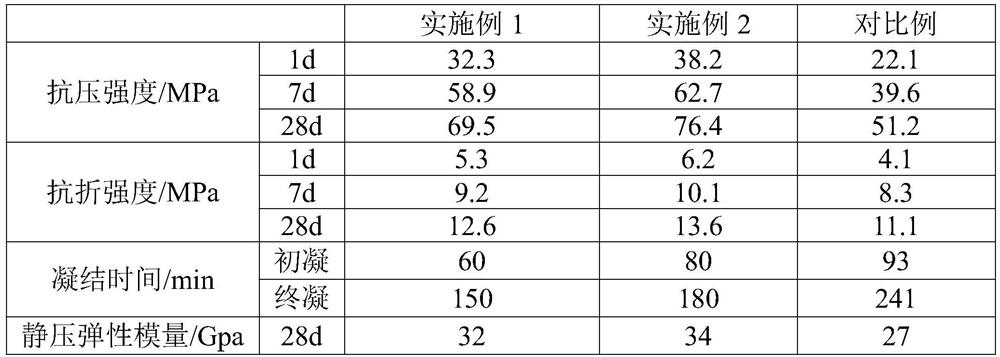

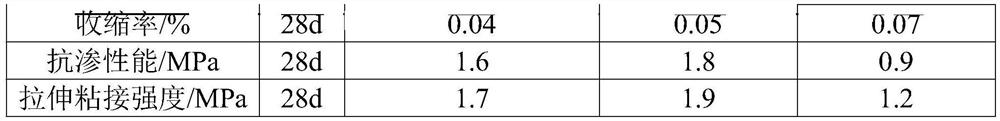

Examples

preparation example Construction

[0023] In another aspect, the present invention also provides a method for preparing the aforementioned concrete repairing material, which includes: soaking the water-absorbing resin in the non-alkali liquid quick-setting agent, heating and drying to constant weight, and obtaining the non-alkali Alkali liquid quick-setting agent modified water-absorbing resin; after mixing water-reducing agent, waterproof rubber powder, and organic additives, a premix is prepared; cement, sand, mineral admixture, fiber and non-alkali liquid quick-setting agent are modified After the water-absorbing resin is mixed, it is added into the premixed material to obtain mortar powder; after adding water and stirring the mortar powder, the concrete repair material is obtained.

[0024] Specifically, soak the water-absorbent resin in an alkali-free liquid quick-setting agent with a concentration of not less than 50% for 24 hours, then put it into a vacuum heating drying oven, vacuumize and heat the wat...

Embodiment 1

[0026] A concrete repair material, which is composed of the following raw materials in parts by mass: 480 parts by mass of Portland cement, 50 parts by mass of ultrafine slag, 450 parts by mass of quartz sand of 40-60 mesh, 2.5 parts by mass of polycarboxylate superplasticizer, 10 parts by mass of waterproof rubber powder, 2 parts by mass of polypropylene fiber, 0.1 part by mass of defoamer, and 5 parts by mass of non-alkali liquid quick-setting agent modified water-absorbing resin.

[0027] Wherein, the preparation method of the concrete repair material is as follows: Weigh 20 parts by mass of water-absorbent resin with a particle size of 1.5 mm, put it into an alkali-free liquid quick-setting agent with a concentration of 45%, soak it for 24 hours, and then filter the water-absorbent resin Take it out and put it into a tray, put the tray into a vacuum heating drying oven, vacuumize it, heat it and dry it to constant weight, and then prepare the non-alkali liquid quick-setting...

Embodiment 2

[0032] A concrete repair material, which is composed of the following raw materials in parts by mass: 500 parts by mass of ordinary portland cement, 50 parts by mass of silica fume, 400 parts by mass of quartz sand of 40-60 mesh, and 3 parts by mass of polycarboxylate superplasticizer , 15 parts by mass of waterproof rubber powder, 3 parts by mass of basalt fiber, 0.5 part by mass of starch ether, and 3 parts by mass of non-alkali liquid accelerator modified water-absorbing resin.

[0033] Wherein, the preparation method of described concrete restoration material is:

[0034] Weigh 20 parts by mass of water-absorbent resin with a particle size of 1.2mm and put it in an alkali-free liquid quick-setting agent with a concentration of 40%. After soaking for 24 hours, use a filter device to take out the water-absorbent resin and put it into a tray, and put the tray into vacuum heating In the drying oven, vacuumize and heat and dry to constant weight to prepare the non-alkali liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com