Large-scale continuous culture method of gambierdiscus

A cultivation method and expanded cultivation technology, applied in the field of large-scale continuous cultivation of algae gambiae, can solve the problems of incomplete application, difficult purification, large-scale cultivation, long growth cycle, etc., achieve weight reduction, increase density and vitality, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

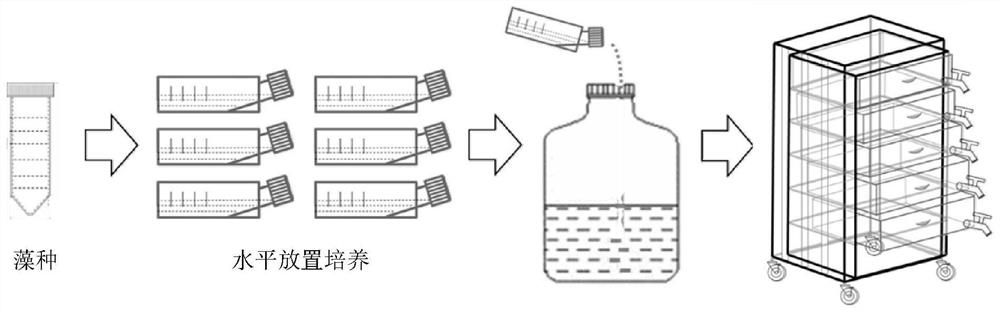

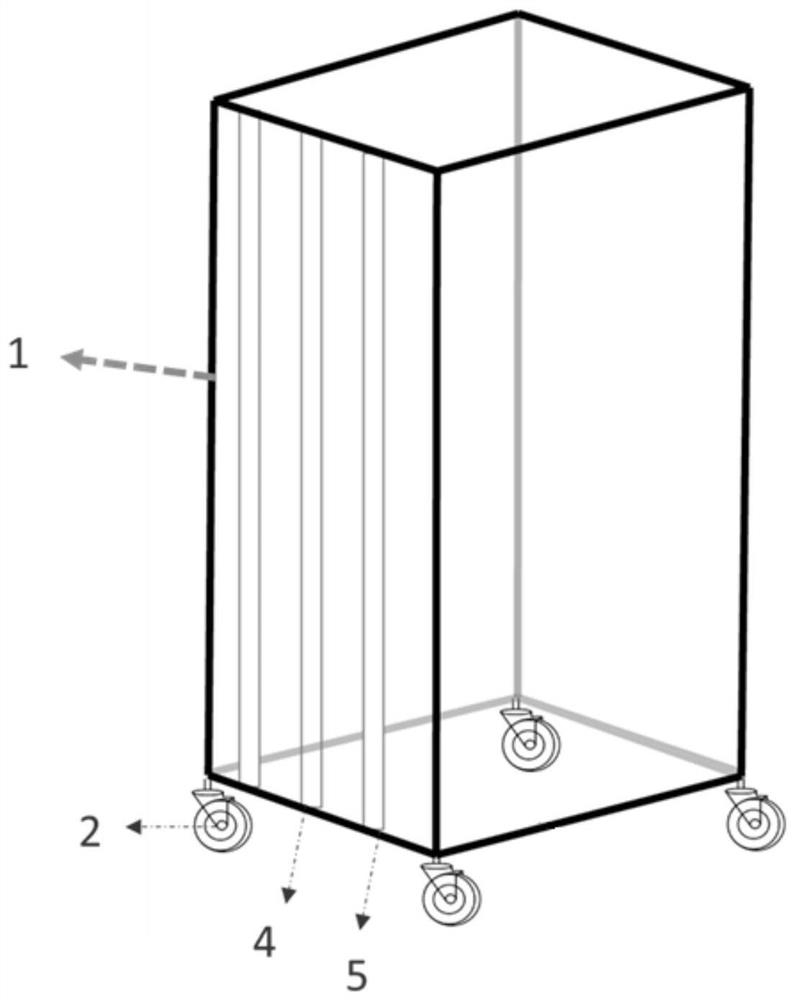

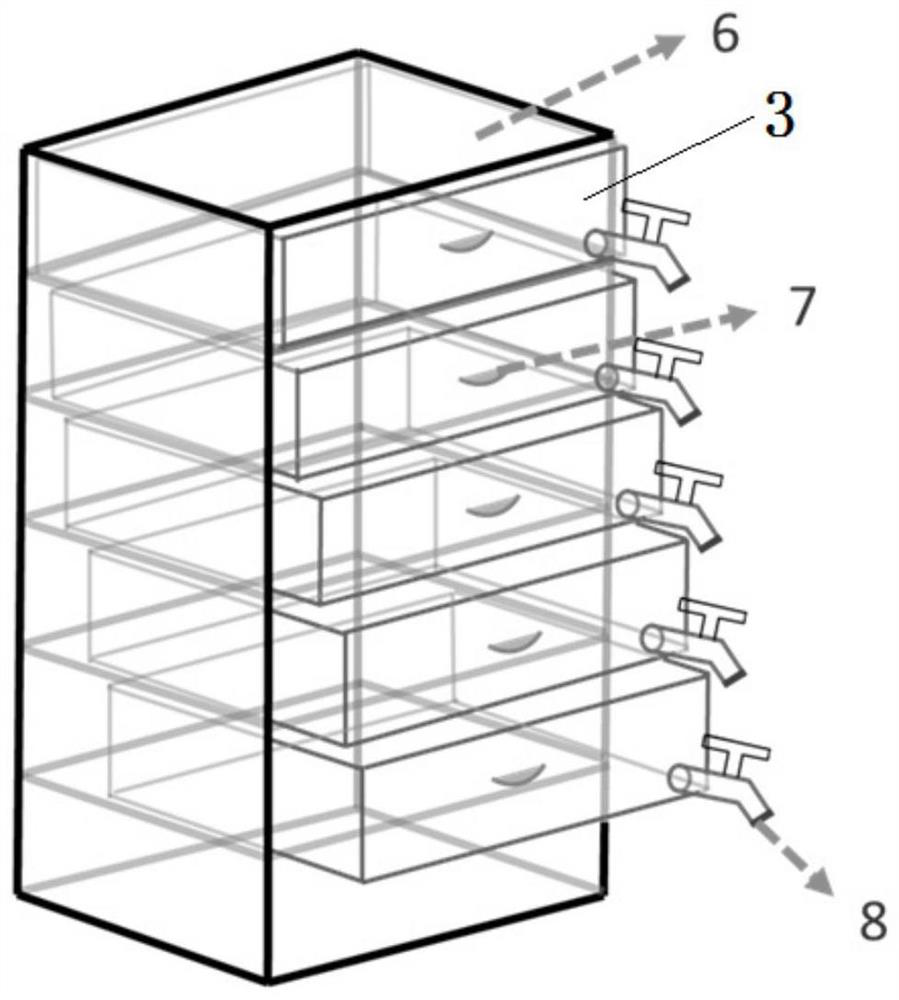

[0035] The selected raw materials of the present invention can be obtained through commercial channels. Such as figure 1 Shown, the cultivation method of gambiae in the present embodiment, at first is to the algae species expansion cultivation of gambiae in order to preserve the good alga seed source of sufficient state, then takes the algae liquid in the culture bottle and transfers to the photobioreactor to adjust to Cultivate and collect after suitable temperature and light.

[0036] Specifically include the following steps:

[0037] 1. Laboratory expansion of algae gambiae

[0038] 1. Configure liquid culture medium

[0039] Configure the required nutrient salts, using L1 medium (without adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com