Device for inhibiting hydraulic jump or oscillation phenomenon in built-in voltage stabilizer

A voltage stabilizer and water suppression technology, which is applied in the direction of non-uniform reactors, thermal reactors, nuclear reactors, etc., can solve the problems of reduced primary circuit pressure safety, reduced space diameter-to-height ratio, and large space occupied by partitions to achieve Simple installation and maintenance, reduction of harmful vibration, and obvious suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

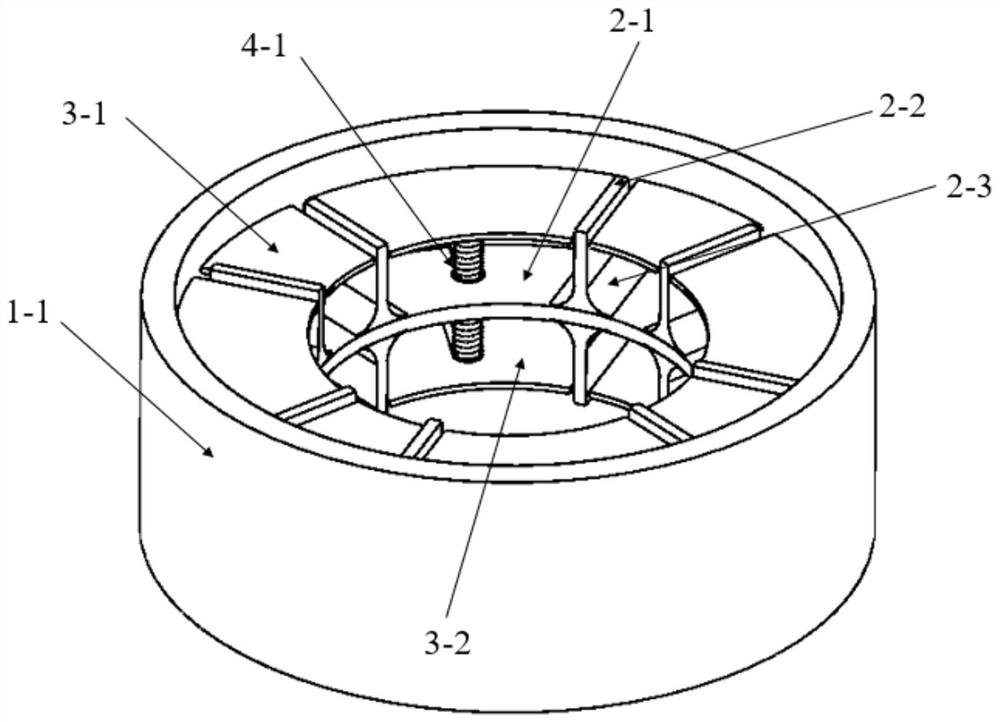

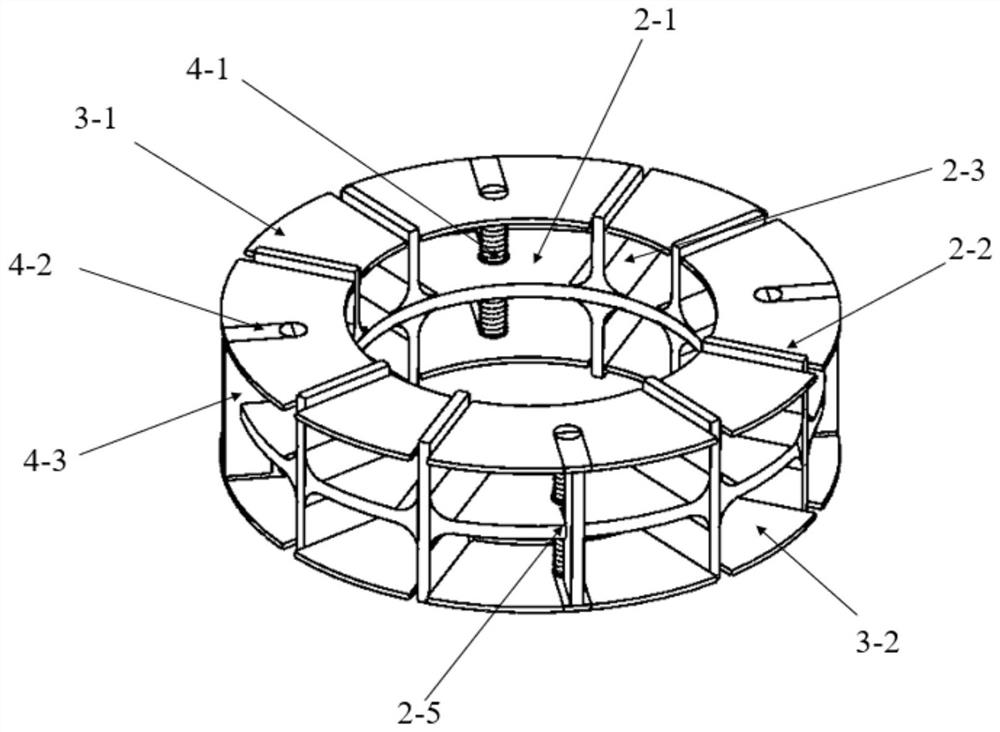

[0033] according to figure 1 and figure 2 , the wall surface 1-1 of the container body mainly refers to the wall surface of the built-in pressurizer of the integrated chamber reactor, and may also refer to the wall surface of other important liquid-carrying containers that are prone to hydraulic jumps or liquid tank sloshing phenomena, and its shape, specification, and model Parameters such as size, material, etc. should be determined according to its objective requirements. As the object of installation and function of this device, its parameters should not be affected by the device.

[0034] according to figure 1 , image 3 and Figure 4 , the self-adaptive heterogeneous baffles are mainly arranged near the water surface of the pressurizer, self-adaptive refers to highly self-adaptive, and can automatically change near the liquid surface according to the water content or liquid level height, and can play the best role. Inhibition effect, to avoid the negative effect of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com