A high-frequency and high-power impatt tube electric parameter debugging device

A parameter debugging, high-power technology, applied in circuits, short-circuit testing, electrical components, etc., can solve the problem of inability to debug the electrical parameters of IMPATT diodes, and achieve the effects of mechanical tuning thickness adjustment, easy assembly, and improved debugging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

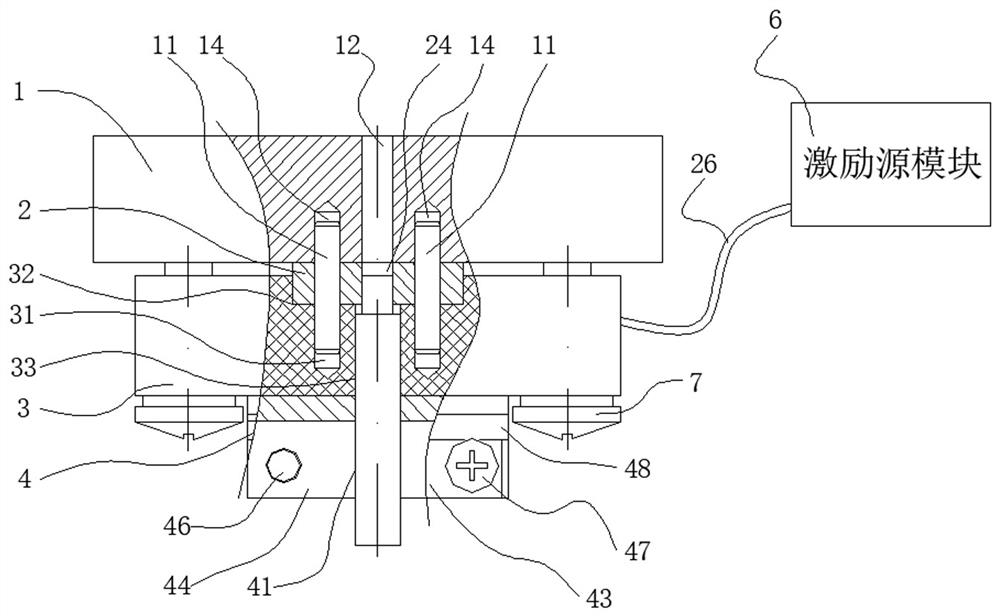

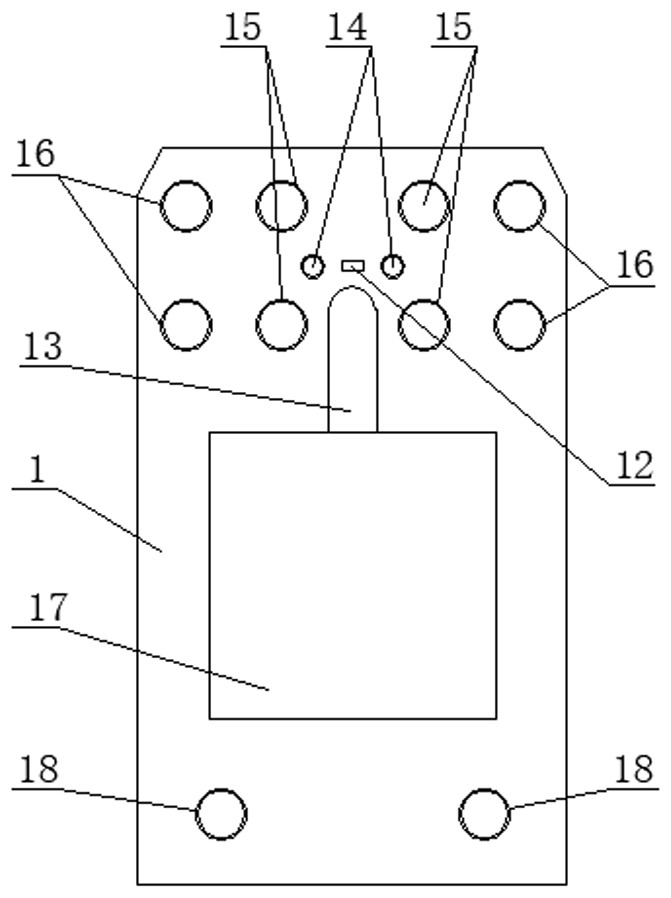

[0027] In order to make the present invention clearer, a kind of high-frequency high-power IMPATT tube electrical parameter debugging device of the present invention will be further described below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention and are not used to limit the present invention. .

[0028] This embodiment is based on the existing IMPATT tube tooling to realize the purpose of debugging the electrical parameters of the high-frequency and high-power IMPATT tube. The specific structure of the tooling here is disclosed in the Chinese patent application number 202011165255.5 "A Waveguide Output Carrying Device".

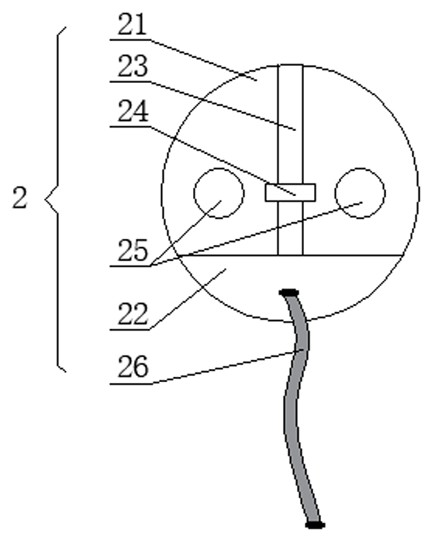

[0029] Such as figure 1 As shown, the tooling part 2 includes a conical main body 21, and a step 22 is provided on the lower side of the upper surface of the main body 21. The excitation source feeder 26 is connected and drawn out on the step 22, and the upper surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com