Energy-saving high-strength autoclaved sand-lime brick production and processing method

A technology of autoclaved lime-sand bricks and processing methods, which is applied in the field of building materials, can solve the problems of limited service life, easy weathering of lime-sand bricks, and reduce use intensity, so as to achieve the effects of saving resources, avoiding cracks, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

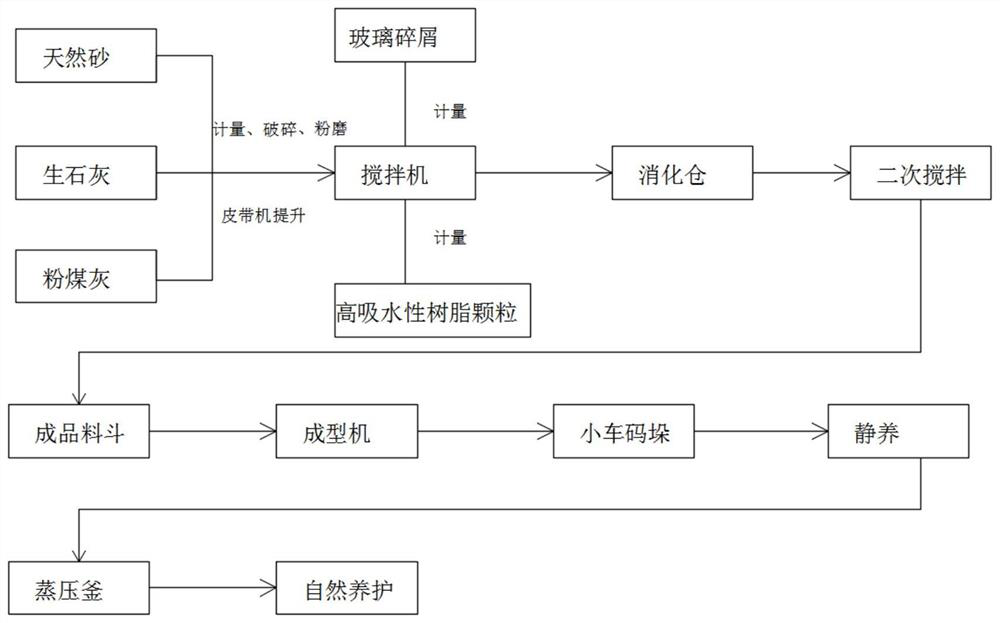

[0024] In summary, specific embodiment one is given below: the preparation method of autoclaved lime-sand brick comprises the following steps:

[0025] S1, send 20% of natural sand, 20% of quicklime, and 20% of fly ash into the jaw crusher for crushing. The particle size of the crushed raw materials is 30mm-85mm, and then sent to the coarse lime bin by the elevator, and fed by the impeller. The machine is supplied to the dry ball mill for grinding, and the ground is ground to an 80um hole sieve, and the remaining 10% of the sieve, the raw material after grinding is sent to the fine lime bin through the bucket elevator, and is measured by the lime measuring hopper;

[0026] S2. Grind 20% of the glass crumbs into powder, sieve and measure, mix with the above-mentioned raw materials and 5% of the superabsorbent resin particles according to the requirements of the mixing ratio, add an appropriate amount of water and stir to form a uniform mixture, add water, once After stirring an...

specific Embodiment 2

[0030] Provide specific embodiment two below: the preparation method of autoclaved lime-sand brick comprises the following steps:

[0031] S1, send 25% of natural sand, 25% of quicklime, and 30% of fly ash into the jaw crusher for crushing. The particle size of the crushed raw materials is 30mm-85mm, and then sent to the coarse lime bin by the elevator, and fed by the impeller. The machine is supplied to the dry ball mill for grinding, and the ground is ground to an 80um hole sieve, and the remaining 15% is sieved. The raw material after grinding is sent into the fine lime bin through the bucket elevator, and is measured by the lime measuring hopper;

[0032] S2. Grind 25% of the glass crumbs into powder, sieve and measure, mix with the above-mentioned raw materials and 10% of the superabsorbent resin particles according to the requirements of the mixing ratio, add an appropriate amount of water and stir to form a uniform mixture, add water, once After stirring and digestion, ...

specific Embodiment 3

[0036] Provide specific embodiment three below: the preparation method of autoclaved lime-sand brick comprises the following steps:

[0037] S1, send 30% of natural sand, 40% of quicklime, and 40% of fly ash into the jaw crusher for crushing. The particle size of the crushed raw materials is 30mm ~ 85mm, and then sent to the coarse lime bin by the elevator, and fed by the impeller The machine is provided to the dry ball mill for grinding, and the ground is ground to an 80um hole sieve, and the remaining 20% of the sieve, the raw material after grinding is sent to the fine lime bin through the bucket elevator, and is measured by the lime measuring hopper;

[0038] S2. Grind 30% of the glass crumbs into powder, sieve and measure, mix with the above-mentioned raw materials and 15% of the superabsorbent resin particles according to the requirements of the mixing ratio, add an appropriate amount of water and stir to form a uniform mixture, add water, once After stirring and diges...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com