Flame retardant, flame-retardant and smoke-suppression composite material and preparation method

A technology of composite materials and flame retardants, which is applied in the fields of flame retardants, flame retardant and smoke suppression composite materials and their preparation, and can solve problems such as deterioration of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

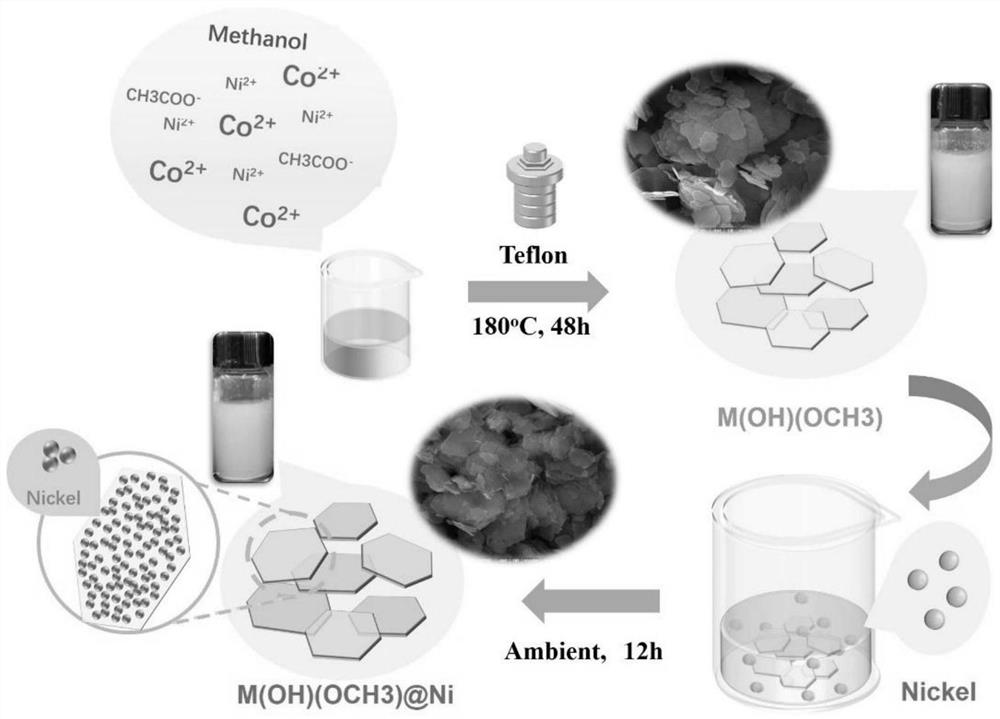

[0035] M(OH)(OCH 3 ) is prepared as follows:

[0036] Ni(OH)(OCH 3 ), Co(OH)(OCH 3 ) or Mg(OH)(OCH 3 ) The preparation method has been recorded and prepared in the existing literature, and will not be described too much here;

example 1

[0037] Example 1, the preparation of M(OH)(OCH containing Ni and Co two elements 3 ), the M(OH)(OCH 3 ) is expressed as CoNi(OH)(OCH 3 ), and its preparation process includes as follows: cobalt acetate tetrahydrate and nickel acetate tetrahydrate are premixed according to the molar ratio of Ni:Co of 1:9 and then dissolved in methanol, and the precursor is obtained after vigorous stirring for 12h. The body was sealed in a Teflon reactor, and it was placed in an oven at 180 degrees Celsius for 48 hours, and then filtered three times with methanol to obtain the first product, which was dried overnight in a 60 degrees Celsius oven for 8-12 hours to obtain CoNi(OH)(OCH containing Ni and Co 3 ) lavender uniform powder, at this time CoNi(OH)(OCH 3 ) in the ratio range of Ni:Co is 0.1-1;

example 2

[0038] Example 2, the preparation of M(OH)(OCH containing Mg and Co two elements 3 ), the M(OH)(OCH 3 ) is expressed as MgCo(OH)(OCH 3 ), the preparation process includes the following steps: cobalt acetate tetrahydrate and magnesium acetate tetrahydrate are premixed in a molar ratio of Mg:Co of 1:9 and then dissolved in methanol, and the precursor is obtained after vigorously stirring for 12 hours. The body was sealed in a Teflon reactor, and it was placed in an oven at 180 degrees Celsius for 48 hours, and then filtered three times with methanol to obtain the first product, which was dried overnight in a 60 degrees Celsius oven for 8-12 hours to obtain MgCo(OH)(OCH) containing two elements of Mg and Co 3 ) uniform powder, at this time MgCo(OH)(OC H 3 ) in the ratio range of Mg:Co is 0.1-1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat release | aaaaa | aaaaa |

| heat release | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com