Preparation of micromolecular phosphorus-magnesium flame retardant and application of micromolecular phosphorus-magnesium flame retardant in preparation of flame-retardant copolyester material

A technology of flame-retardant copolyester and flame retardant, which is applied in the direction of hypophosphorous acid, phosphorous acid, phosphorus oxyacid, etc., can solve the problems of affecting the mechanical properties of PET materials, poor dispersion of inorganic hydroxides, and easy agglomeration. Achieve excellent flame retardant and smoke suppression performance, good flame retardant and smoke suppression effect, and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

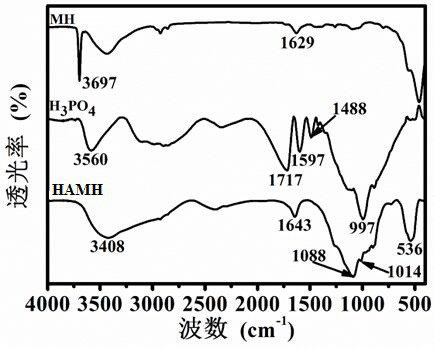

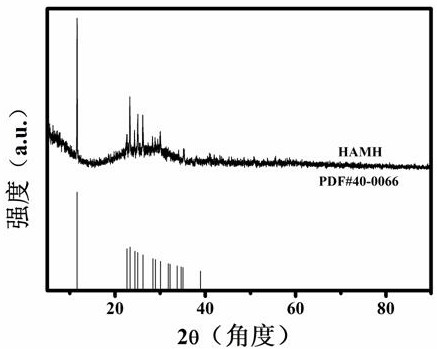

[0039] (1) Add 300 mL of ethanol to a 500 mL round-bottomed flask, weigh 13.64 mL of phosphoric acid and add it to the round-bottomed flask. When the temperature rises to 60°C, the phosphoric acid is completely dissolved in ethanol, and then 5.83 g of magnesium hydroxide is weighed and added to the flask. Among them, the heating temperature was raised to 80°C, the reaction was carried out under stirring conditions for 5 hours, the product was filtered by hot filtration, the product was washed 3 times, and dried in a vacuum oven at 80°C for 6 hours to obtain a white solid powder, which was a phosphorus-magnesium flame retardant.

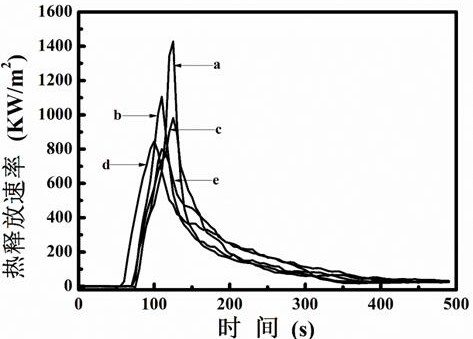

[0040] (2) 498g of terephthalic acid, 242g of ethylene glycol, 0.0498g of antimony trioxide and 4.98g of phosphorus-magnesium flame retardant were added to a 1.5L magnetic stirring reaction kettle, filled with nitrogen to make the pressure reach 0.05MPa, The temperature was raised to 235°C and the reaction was carried out for 4.5 hours. After the ester...

Embodiment 2

[0043] (1) Same as Example 1;

[0044] (2) Add 498g of terephthalic acid, 242g of ethylene glycol, 0.0498g of antimony trioxide and 14.9g of phosphorus-magnesium flame retardant to a magnetic stirring reaction kettle with a volume of 1.5L, and fill with nitrogen to make the pressure reach 0.05MPa , raise the temperature to 235°C and react for 4.5h. After the esterification reaction, remove the moisture produced by the reaction to keep the pressure in the kettle at normal pressure, close the esterification valve, and react at 100°C and normal pressure for 0.5h. After the normal pressure reaction is over, open the polycondensation valve and turn on the vacuum pump. In the semi-vacuum state, the semi-polycondensation reaction is carried out at 250 °C for 0.5 h. After the reaction is completed, the full polycondensation reaction is carried out at 275 °C for 6 h in a full vacuum state, and an appropriate amount of nitrogen is introduced to discharge the material. , dicing and dryin...

Embodiment 3

[0047] (1) Same as Example 1;

[0048] (2) Add 498g of terephthalic acid, 242g of ethylene glycol, 0.0498g of antimony trioxide and 24.9g of phosphorus-magnesium flame retardant into a 1.5L magnetic stirring reaction kettle, fill with nitrogen to make the pressure reach 0.05MPa, The temperature was raised to 235°C and the reaction was carried out for 4.5 hours. After the esterification reaction was completed, the moisture produced by the reaction was removed to keep the pressure in the kettle at normal pressure. After the normal pressure reaction is over, open the polycondensation valve and turn on the vacuum pump. In the semi-vacuum state, the semi-polycondensation reaction is carried out at 250 °C for 0.5 h. After the reaction is completed, the full polycondensation reaction is carried out at 275 °C for 6 h in a full vacuum state, and an appropriate amount of nitrogen is introduced to discharge the material. , dicing and drying to obtain a phosphorus-magnesium halogen-free a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat release rate | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com