Liquid disperse dye for high-temperature dip dyeing and preparation method thereof

A technology of liquid disperse dyes and disperse dyes, applied in the field of printing and dyeing, which can solve the problems that limit the wide application of liquid disperse dyes, and achieve the effects of preventing collision agglomeration, strong dispersibility, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, the preparation of liquid disperse dyes for high temperature exhaust dyeing:

[0022] a) Take 9g of compound dispersant, 45g of disperse dye filter cake and 246g of water and mix them evenly in the dyeing cup, then add glass beads with a diameter of 2mm and use RW-20 digital display electric mixer to pre-grind for 30min, pre-grinding speed Be 900r / min, obtain pre-grinding dye, described compound dispersant is the mixed dispersant of anionic dispersant and nonionic dispersant, the mass ratio of anionic dispersant and nonionic dispersant in described compound dispersant is 6:4;

[0023] Among them, the filter cake of disperse dye is disperse blue 79 filter cake; ;

[0024] b) After adding zirconia beads with a diameter of 1mm into the pre-grinding dye prepared in step a), use a sander for secondary grinding for 2 hours, and the secondary grinding speed is 2800r / min to obtain a liquid disperse dye for high-temperature exhaust dyeing.

Embodiment 2

[0025] Embodiment two, the storage stability test of liquid disperse dye for high temperature exhaust dyeing:

[0026] The liquid disperse dye prepared in Example 1 is tested for storage stability, and the stability of the liquid disperse dye at room temperature and 60° C. is shown in Table 1 and Table 2:

[0027] Days at room temperature 0 7 14 21 28 Particle size (nm) 158.2 160.6 165.7 170.1 183.6 PDI 0.204 0.204 0.206 0.208 0.211

[0028] Table 1 Stability of liquid disperse dyes for high temperature exhaust dyeing at normal temperature

[0029] Storage days at 60°C 0 7 14 21 28 Particle size (nm) 158.2 165.6 174.2 185.4 200.7 PDI 0.204 0.207 0.209 0.213 0.214

[0030] Table 2 Stability of liquid disperse dyes for high temperature exhaust dyeing at 60°C

[0031] As shown in Table 1 and Table 2 above, the storage stability of liquid disperse dyes for high-temperature exhaust dyeing prepared by thi...

Embodiment 3

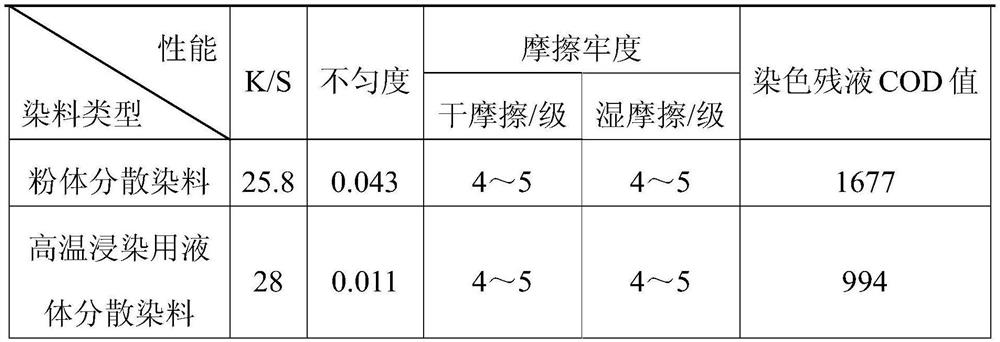

[0032] Embodiment 3, performance test comparison of liquid disperse dyes for high temperature exhaust dyeing and powder disperse dyes under high temperature and high pressure dyeing conditions:

[0033] At the same concentration, the liquid disperse dyes for high-temperature exhaust dyeing prepared in Example 1 and the commercially available powder disperse dyes were used to dye polyester fabrics under high temperature and high pressure respectively, and the dyeing properties between the two were compared. The results are shown in Table 3 below. Show:

[0034]

[0035] Table 3 Dyeing performance indicators of liquid disperse dyes and powder disperse dyes for high temperature exhaust dyeing

[0036] As shown in Table 3 above, the rubbing fastness of liquid disperse dyes for high-temperature exhaust dyeing can reach the rubbing fastness of powder disperse dyes, while the K / S and unevenness of liquid disperse dyes for high-temperature exhaust dyeing are obviously better than t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com