Teflon coated metal net and preparation method thereof

A technology of metal mesh and Teflon, which is applied in coatings, devices for coating liquid on the surface, and surface pretreatment, etc., can solve the problem of Teflon-coated metal mesh service life limit, Teflon shedding, Teflon Solve the problems of low surface energy of dragon molecules to achieve the effect of improving binding degree, reducing damage and increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0040] The raw materials used in the preparation examples of this application can all be obtained from the market, wherein the bagasse is selected from the bagasse (ground to an average particle size of 80 μm) sold by the Xinlaishun Agricultural Products Waste Management Department of Wuming County, and the acetone is purchased from Nanjing For Zhenmu Chemical Co., Ltd., phosphoric acid is selected from industrial-grade orthophosphoric acid sold by Shandong Hongyunchang Chemical Technology Co., Ltd., and phosphorus oxychloride is selected from industrial-grade phosphorus oxychloride sold by Shandong Anqiang Chemical Co., Ltd.

preparation example 1

[0043] In this preparation example, the carbonization aid is prepared according to the following method:

[0044] (1) 70kg of bagasse with a moisture content of 63% is mixed with 980kg of acetone to obtain a bagasse dispersion;

[0045] (2) Add 12 kg of phosphoric acid to the bagasse dispersion, heat at 58° C. for 2.5 hours, and then evaporate the acetone to obtain the charring aid.

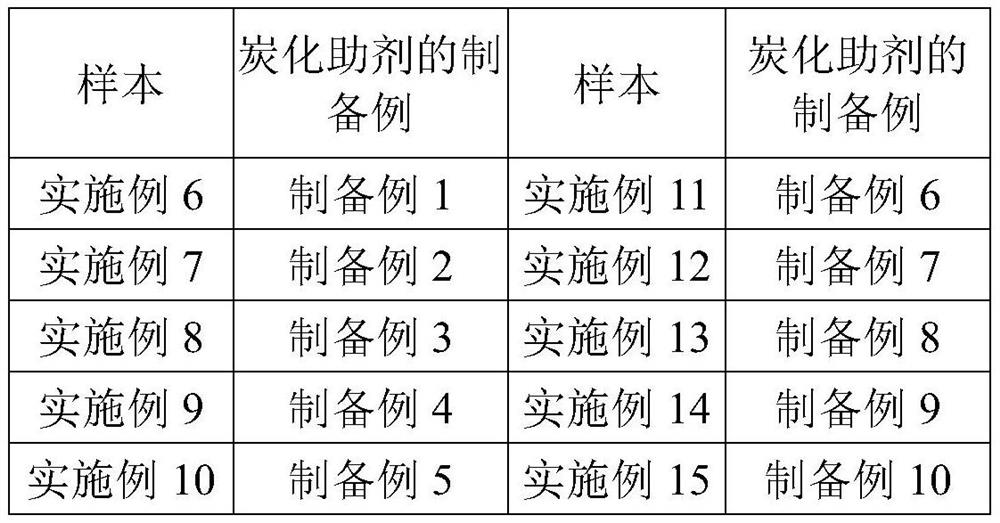

[0046] As shown in Table 1, the difference between Preparation Examples 1-5 lies in the different raw material proportions of the charring aids.

[0047] Table 1

[0048] sample Bagasse / kg Phosphoric acid / kg Preparation Example 1 70 12 Preparation example 2 75 13 Preparation example 3 80 14 Preparation Example 4 85 15 Preparation Example 5 90 16

preparation example 6

[0050] The difference between this preparation example and preparation example 1 is that the formula of the charring aid also includes 8 kg of phosphorus oxychloride, and the phosphorus oxychloride is mixed together with the bagasse dispersion in step (2).

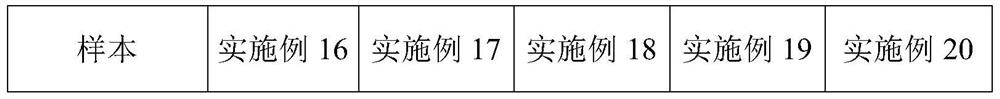

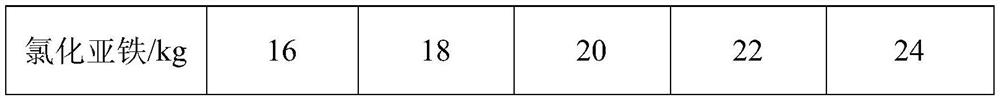

[0051] As shown in Table 2, the difference between Preparation Examples 6-10 is that the amount of phosphorus oxychloride is different.

[0052] Table 2

[0053] sample Preparation Example 6 Preparation Example 7 Preparation example 8 Preparation Example 9 Preparation Example 10 Phosphorus oxychloride / kg 8 9 10 11 12

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap