Preparation method of non-woven material based on semi-finished textile

A technology of non-woven materials and semi-finished products, applied in the field of non-woven materials, can solve the problems of low strength, limit the combination effect of textile technology and non-woven technology, etc., and achieve simple and easy technology, rich and diverse types, environmental protection and pollution-free production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

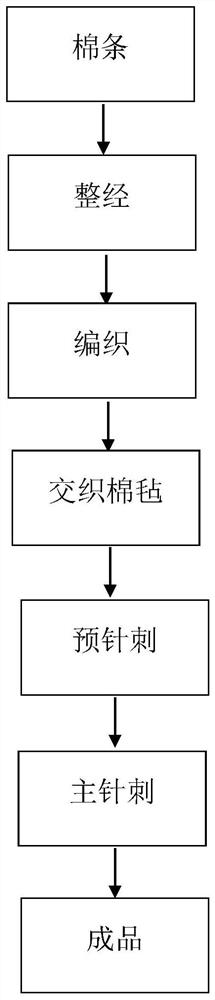

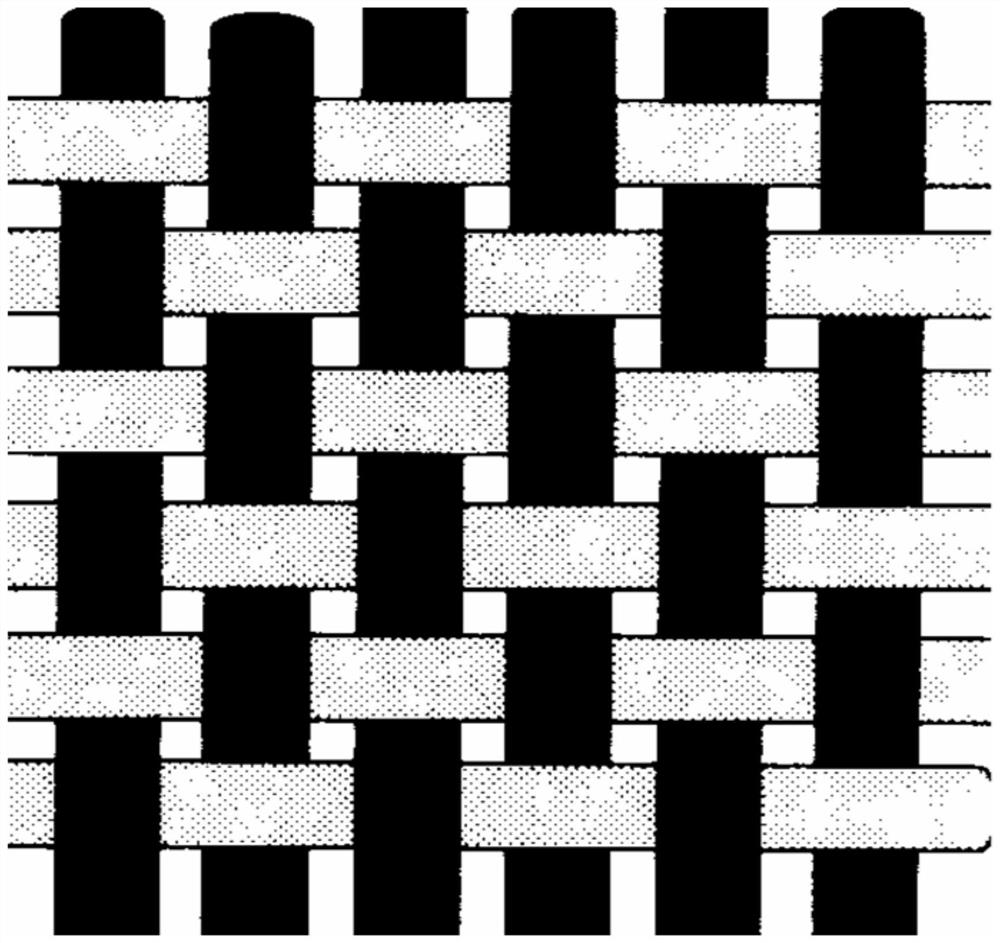

[0026] Such as figure 1 As shown, the present embodiment provides a kind of preparation method of the non-woven material based on spinning semi-finished product, and described non-woven material is processed by the cotton fiber sliver of spinning mill as raw material, and present embodiment first quantifies The cotton slivers of 27g / 5m are arranged according to the warp density of 5 pieces / 10cm as the warp strips, and the weft strips are introduced according to the plain weave structure for weaving to obtain interwoven fabrics with a weft density of 5.5 pieces / 10cm, and then the interwoven fabrics are sent to Enter the acupuncture machine for pre-acupuncture, and the acupuncture frequency is 300r / min.

[0027] Make preliminary reinforcement, and then the product after pre-acupuncture undergoes 1 main acupuncture reinforcement forming, the acupuncture frequency is 600r / min; the final product weight is 500g / m 2 .

[0028] The structural diagram of the nonwoven material prepare...

Embodiment 2

[0030] This embodiment provides a method for preparing non-woven materials based on spinning semi-finished products. The non-woven materials are processed from raw cotton fiber slivers in spinning mills. The preparation method is as follows: first, quantitatively 30g / 5m cotton slivers are arranged according to the warp density of 5 pieces / 10cm as the warp strips, and the weft strips are introduced according to the plain weave structure for weaving to obtain interwoven fabrics with a weft density of 5 pieces / 10cm, and then the interwoven fabrics are fed into Acupuncture machine was used for pre-acupuncture, and the frequency of acupuncture was 300r / min. Make the initial reinforcement, and then the product after needle punching is reinforced by two front and back spunlaces, the pressure of the spunlace head is 80bar and 100bar respectively; finally, the final product is obtained after drying and finishing, with a grammage of 550g / m 2 .

Embodiment 3

[0032] This embodiment provides a method for preparing non-woven materials based on spinning semi-finished products. The non-woven materials are processed from polyester-cotton 65 / 35 fiber blended raw slivers in spinning mills. The preparation method is : First, the polyester-cotton 65 / 35 fiber blended raw slivers that are quantitatively 25g / 5m are arranged according to the warp density of 8 / 10cm as the warp strips, and the weft strips are introduced into the weft strips according to the plain weave structure for weaving, and the weft density is 8 / 10cm. 10cm interlaced fabric, and then the interlaced fabric is sent to the needling machine for pre-acupuncture, and the needling frequency is 300r / min. Make the preliminary reinforcement, and then the product after acupuncture is reinforced by two front and back spunlaces, the pressure of the spunlace head is 80bar and 120bar respectively; finally, the final product is obtained after drying and finishing, with a grammage of 650g / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com