Anticorrosion coating for sheet metal of air conditioner outdoor unit and preparation method thereof

A technology for air-conditioning outdoor units and anti-corrosion coatings, which is applied in the direction of anti-corrosion coatings, polyester coatings, coatings, etc., which can solve the problems of difficulty in popularization and application, poor overall performance of the coating film, and failure, and achieve improved UV aging resistance and hydrophobicity, enhanced salt spray corrosion resistance, and beneficial to popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

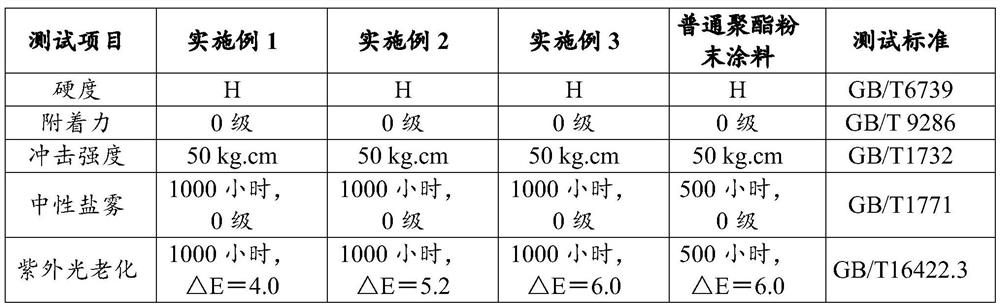

Examples

Embodiment 1

[0031]The anticorrosive coating for the sheet metal of the outdoor air-conditioning cabinet includes the following components in parts by weight: 50 parts of carboxyl-terminated polyester resin, 50 parts of silicone modified polyester resin, and 25 parts of triglycidyl isocyanurate , 10 parts of leveling agent, 1 part of benzoin, 1.0 part of silane coupling agent KH550, 25 parts of titanium dioxide, 5 parts of activated calcium carbonate; wherein the softening point of the carboxy-terminated polyester resin is 85-100°C; The hydroxyl content of the silicone modified polyester resin is 3% to 5%, and the softening point is 85 to 100°C; the leveling agent is a mixture of polyester powder and butyl acrylate polymer emulsion. The mass percentage of butyl acrylate polymerization emulsion is 10%.

[0032]The preparation method is as follows: adding titanium dioxide to the coupling agent, stirring and mixing on a high-speed mixer for 30 minutes; after drying the obtained mixture, triple shrinka...

Embodiment 2

[0034]The anticorrosive coating for the sheet metal of the outdoor air-conditioning cabinet includes the following components in parts by weight: 75 parts of carboxy-terminated polyester resin, 25 parts of silicone modified polyester resin, 15 parts of triglycidyl isocyanurate , 7.5 parts of leveling agent, 0.75 parts of benzoin, 0.75 parts of silane coupling agent KH560, 15 parts of titanium dioxide, 15 parts of activated calcium carbonate; wherein the softening point of the carboxy-terminated polyester resin is 85-100°C; The hydroxyl content of the silicone modified polyester resin is 3% to 5%, and the softening point is 85 to 100°C; the leveling agent is a mixture of polyester powder and butyl acrylate polymer emulsion. The mass percentage of butyl acrylate polymer emulsion is 10%.

[0035]The preparation method is as follows: adding titanium dioxide to the coupling agent, stirring and mixing on a high-speed mixer for 30 minutes; after drying the obtained mixture, triple shrinkage w...

Embodiment 3

[0037]The anticorrosive coating for the sheet metal of the outdoor air-conditioning cabinet includes the following components in parts by weight: 90 parts of carboxy-terminated polyester resin, 10 parts of silicone modified polyester resin, and 10 parts of triglycidyl isocyanurate , 5 parts of leveling agent, 0.5 parts of benzoin, 0.5 parts of silane coupling agent KH570, 5 parts of titanium dioxide, 25 parts of activated calcium carbonate; wherein the softening point of the carboxy-terminated polyester resin is 85-100°C; The hydroxyl content of the silicone modified polyester resin is 3% to 5%, and the softening point is 85 to 100°C; the leveling agent is a mixture of polyester powder and butyl acrylate polymer emulsion. The mass percentage of butyl acrylate polymer emulsion is 10%.

[0038]The preparation method is as follows: adding titanium dioxide to the coupling agent, stirring and mixing on a high-speed mixer for 30 minutes; after drying the obtained mixture, triple shrinkage wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com