AlGaN-based deep ultraviolet LED epitaxial structure of In-Si co-doped quantum well and preparation method of AlGaN-based deep ultraviolet LED epitaxial structure

An epitaxial structure and co-doping technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor material quality and unsatisfactory reliability, reduce non-radiative recombination centers, improve internal quantum efficiency, and improve reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

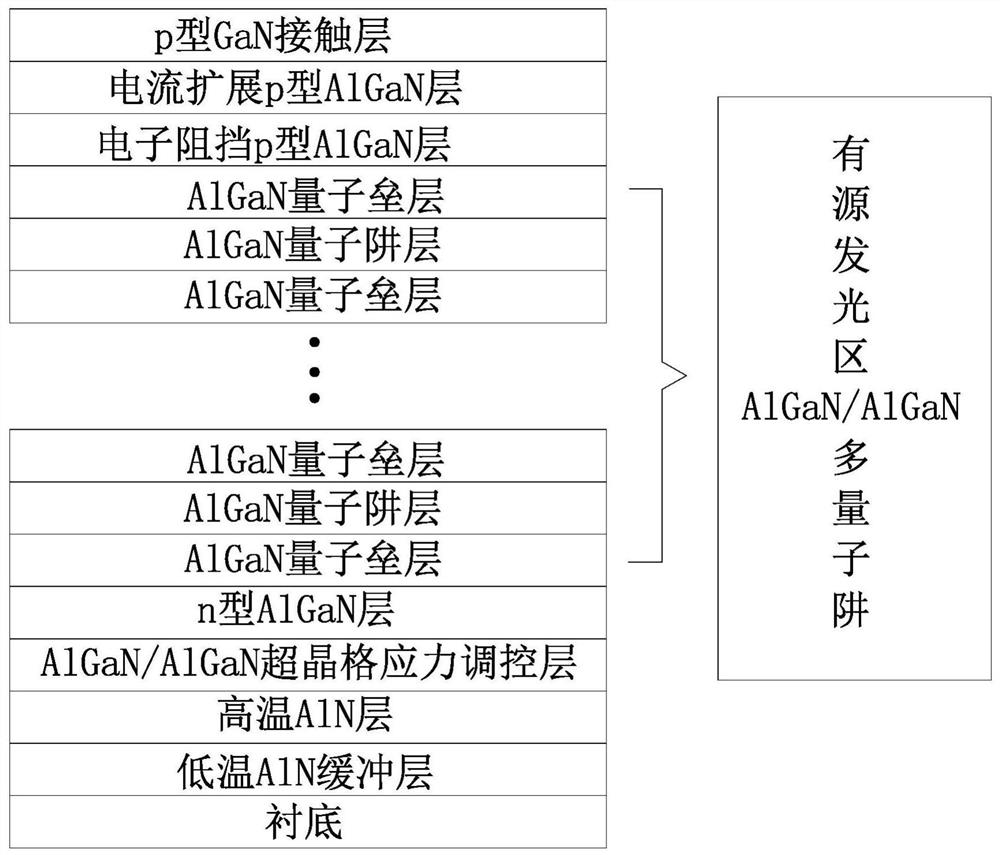

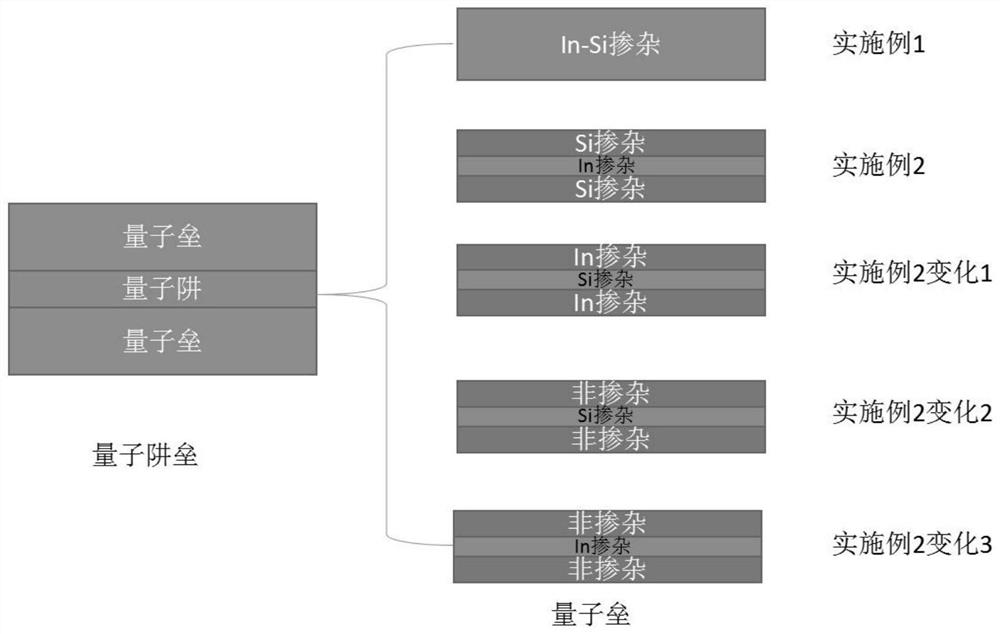

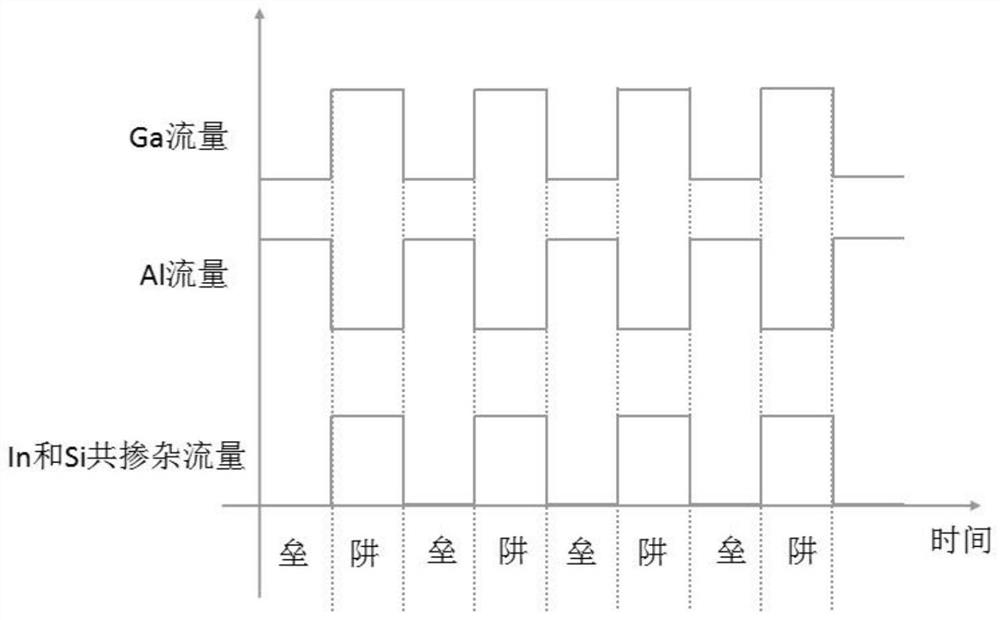

[0026] Embodiment 1: A method for preparing an In-Si co-doped quantum well AlGaN-based deep ultraviolet LED epitaxial structure provided in this embodiment comprises the following steps:

[0027] (1) Place the C-face sapphire as the substrate in the MOCVD graphite carrier plate, and place it at a temperature of 1200-1400°C, a pressure of 75-200torr, and a H 2 and N 2 Under the condition of mixed gas as carrier gas, wash for 5 minutes;

[0028] (2) At a temperature of 950°C, a pressure of 80torr, a V / III ratio of 1000, and a H 2 and N 2 Under the condition of mixed gas as carrier gas, Al source and ammonia gas are passed into the reaction chamber to grow a low-temperature AlN buffer layer with a thickness of 300nm;

[0029] (3) At a temperature of 1300°C, a pressure of 80torr, a V / III ratio of 1000, and a H 2 and N 2 Under the condition of mixed gas as the carrier gas, the Al source and ammonia gas are passed into the reaction chamber to grow a high-temperature AlN layer w...

Embodiment 2

[0037] Embodiment 2: A method for preparing an In-Si co-doped quantum well AlGaN-based deep ultraviolet LED epitaxial structure provided in this embodiment includes the following steps:

[0038] (1) Place the C-face sapphire as the substrate in the MOCVD graphite carrier plate, and place it at a temperature of 1200-1400°C, a pressure of 75-200torr, and a H 2 and N 2 Under the condition of mixed gas as carrier gas, wash for 5 minutes;

[0039] (2) At a temperature of 950°C, a pressure of 80torr, a V / III ratio of 1000, and a H 2 and N 2 Under the condition of mixed gas as carrier gas, Al source and ammonia gas are passed into the reaction chamber to grow a low-temperature AlN buffer layer with a thickness of 300nm;

[0040] (3) At a temperature of 1300°C, a pressure of 80torr, a V / III ratio of 1000, and a H 2 and N 2 Under the condition of mixed gas as the carrier gas, the Al source and ammonia gas are passed into the reaction chamber to grow a high-temperature AlN layer wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com