Preparation method of Kovar alloy wrapped Cu core composite bar

A technology of composite rods and alloys, which is applied in the field of preparation of Kovar alloy-wrapped Cu core composite rods, can solve the problems of strict pretreatment requirements, lack of solutions, complex processes, etc., and achieve good matching sealing, good conductivity, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

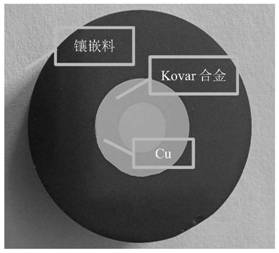

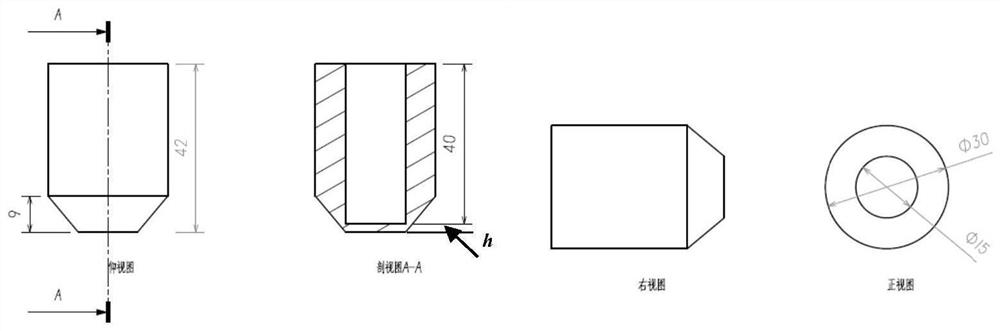

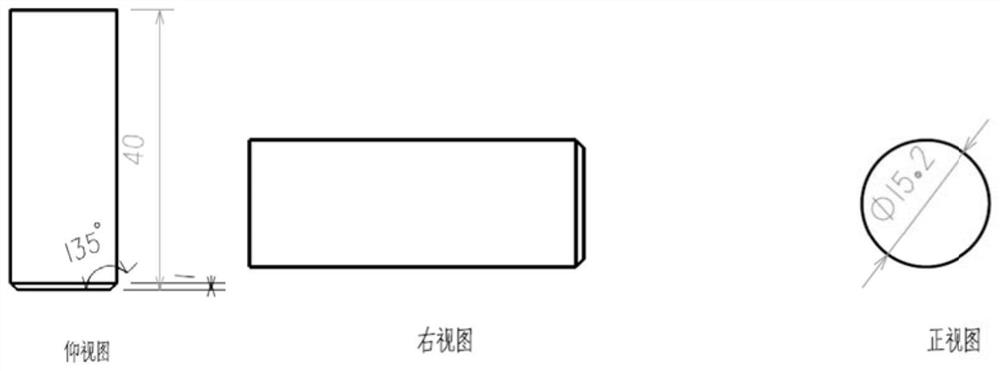

[0037] (1) Preparation of ingots: purchased Ф42mm×45mm 4J29 alloy rods, the size of which is Ф30mm×42mm-Фinside 15mm×40mm 4J29 alloy cylinders after the blind hole is drilled on the wagon, and the bottom is chamfered (such as figure 1 as shown); Purchased Ф16mm×40mm Cu bar, the size after wagon is Ф15.2mm×40mm, bottom chamfer (such as figure 2 shown); the inner and outer surfaces of the 4J29 alloy cylinder and the surface of the Cu rod were polished and dried with acetone, and the Cu core was embedded in the 4J29 alloy cylinder with a press to prepare an interference fit 4J29 alloy / Cu composite ingot ( Such as image 3 shown).

[0038] (2) Pre-heat treatment: 4J29 alloy / Cu composite ingot is placed in a vacuum furnace and heated with the furnace, the heating rate is 5°C / min, the heat treatment temperature is 990°C, the holding time is 3 hours, and then slowly cooled to room temperature with the furnace and released from the furnace .

[0039] (3) Hot extrusion: heat the co...

Embodiment 2

[0044] Taking the 4J29 / CuФ10mm product as an example, the process flow and process parameters adopted in the present invention are as follows:

[0045] (1) Preparation of ingot: Outsourced Ф42mm×45mm 4J29 alloy bar, the size after the wagon is perforated is Ф40mm×42mm-Фinside 20mm×40mm 4J29 alloy cylinder, chamfered at the bottom, outsourced Ф21mm×40mm Cu rod material, the size of the wagon is Ф20.2mm×40mm, and the bottom is chamfered; the inner and outer surfaces of the 4J29 alloy cylinder and the surface of the Cu rod are surface-polished and cleaned and dried with acetone, and the Cu core is embedded in the 4J29 alloy cylinder with a press to prepare 4J29 alloy / Cu composite ingot with interference fit relationship (such as image 3 shown).

[0046] (2) Pre-heat treatment: 4J29 alloy / Cu composite ingot is placed in a vacuum furnace and heated with the furnace, the heating rate is 5°C / min, the heat treatment temperature is 990°C, the holding time is 3 hours, and then slowly ...

Embodiment 3

[0051] Taking the 4J29 / CuФ10mm product as an example, the process flow and process parameters adopted in the present invention are as follows:

[0052] (1) Preparation of ingot: outsourced Ф52mm×45mm 4J29 alloy bar, the size after the wagon is punched is Ф50mm×42mm-Ф inside 20mm×40mm 4J29 alloy cylinder, chamfered at the bottom, outsourced Ф21mm×40mm Cu rod material, the size of the wagon is Ф20.2mm×40mm, and the bottom is chamfered; the inner and outer surfaces of the 4J29 alloy cylinder and the surface of the Cu rod are surface-polished and cleaned and dried with acetone, and the Cu core is embedded in the 4J29 alloy cylinder with a press to prepare 4J29 alloy / Cu composite ingot with interference fit (such as image 3 shown).

[0053] (2) Pre-heat treatment: 4J29 alloy / Cu composite ingot is placed in a vacuum furnace and heated with the furnace, the heating rate is 5°C / min, the heat treatment temperature is 960°C, the holding time is 4 hours, and then slowly cooled with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com