Environment-friendly modified white latex and preparation method thereof

A white latex, environmentally friendly technology, applied in applications, coatings, inks, etc., can solve the problems of small steric hindrance of polymer bonding main materials, limited improvement in water resistance of white latex, easy brittleness and hardening of white latex, etc. Achieve the effect of not easy to corrode, improve water resistance, and high cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

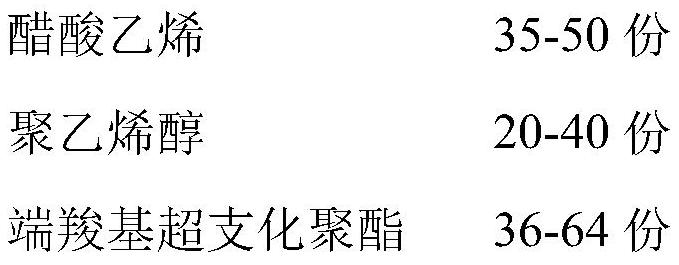

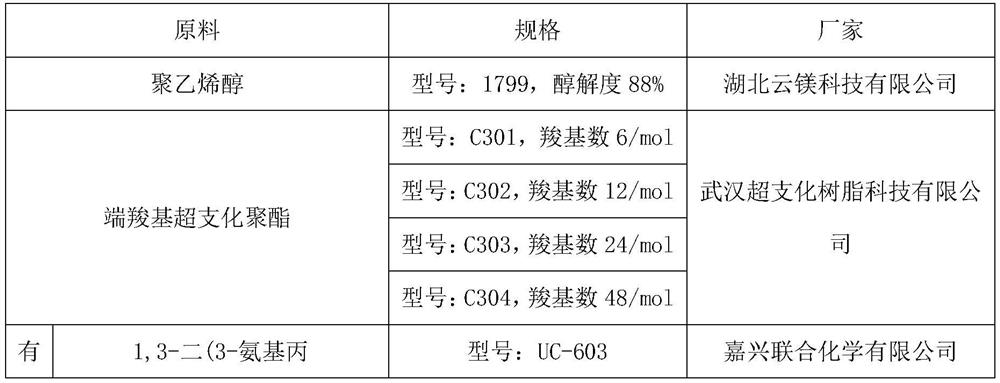

[0042] A kind of environment-friendly modified white latex, its formula is as follows:

[0043] 35g vinyl acetate, 20g polyvinyl alcohol, 36g carboxyl-terminated hyperbranched polyester C301, 7g oxidized starch, 0.1g initiator (sodium persulfate), 3g emulsifier OP-10, 0.05g kaolin (particle size 5 μm), 300g Ionized water;

[0044] Prepared according to the following preparation method:

[0045] S1. Solution preparation:

[0046] Continuously add polyvinyl alcohol to 60g of deionized water, and stir to raise the temperature to 70°C to obtain a polyvinyl alcohol solution, keep it warm for later use;

[0047] Continuously add carboxyl-terminated hyperbranched polyester C301 into 60 g of deionized water, and stir to raise the temperature to 70°C to obtain a carboxyl-terminated hyperbranched polyester solution, which is kept warm for later use;

[0048] Continue to add oxidized starch to 60g of deionized water, and stir to raise the temperature to 40°C to obtain a polyvinyl alco...

Embodiment 2-10

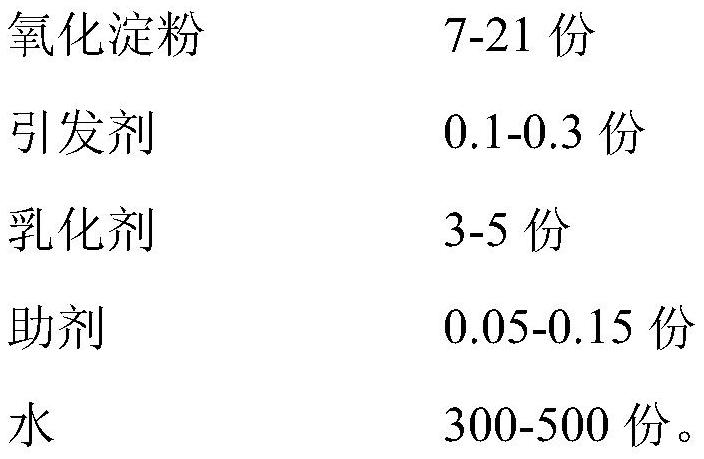

[0052] An environment-friendly modified white latex differs from Example 1 in that: the composition of the raw materials is different, and the specific dosage of each component is shown in the table below.

[0053] Table 2. Composition of modified white latex

[0054] composition Example 1 Example 2 Example 3 Example 4 Example 5 Vinyl acetate / g 35 40 50 40 40 Polyvinyl alcohol / g 20 30 40 36 40 Carboxyl-terminated hyperbranched polyester C301 / g 36 50 64 50 50 Oxidized starch / g 7 14 21 14 14 Sodium persulfate / g 0.1 0.2 0.3 0.2 0.2 OP-10 / g 3 4 5 4 4 Kaolin / g 0.05 0.1 0.15 0.1 0.1 Deionized water / g 300 400 500 400 400 composition Example 6 Example 7 Example 8 Example 9 Example 10 Vinyl acetate / g 40 40 40 40 40 Polyvinyl alcohol / g 40 40 40 40 40 Carboxyl-terminated hyperbranched polyester C301 / g 44 48 48 48 48 Oxidized starch / g 14 14 1...

Embodiment 11-13

[0056] A kind of environment-friendly modified white latex, the difference with embodiment 9 is: the carboxyl number of end carboxyl group hyperbranched polyester is different; wherein the carboxyl number of end carboxyl group hyperbranched polyester in embodiment 11 is 48 / mol; Embodiment The carboxyl number of the carboxyl-terminated hyperbranched polyester in 12 is 12 / mol; the carboxyl number of the carboxyl-terminated hyperbranched polyester in Example 13 is 24 / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com