Bio-based polyether ester reactive polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive, bio-based technology, applied in the field of polyurethane hot-melt adhesives, can solve the problems of gel at the needle, not smooth, and insufficient long-term thermal stability, and achieve the effect of improving comprehensive performance and environmental protection attributes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

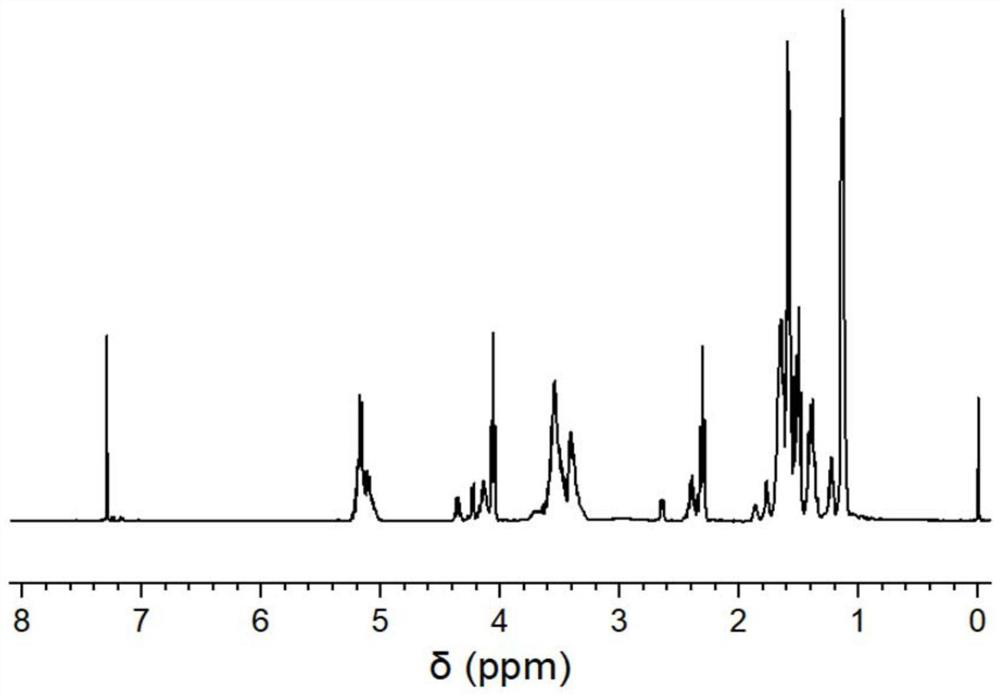

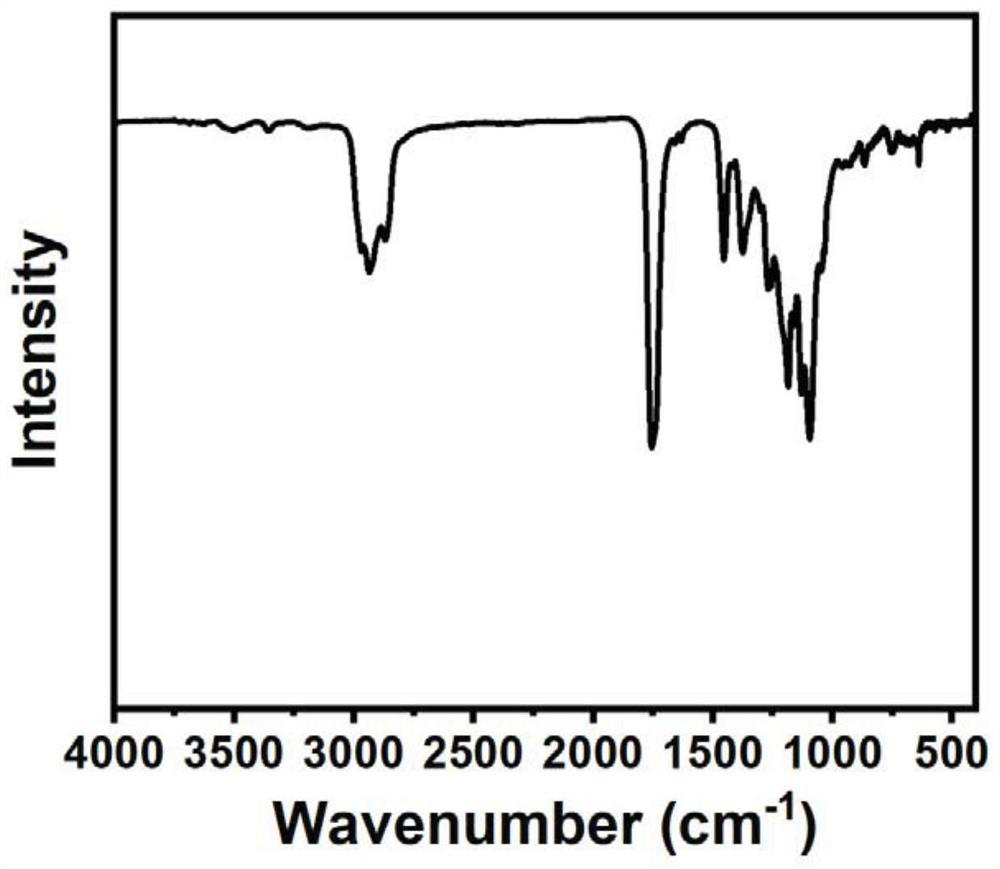

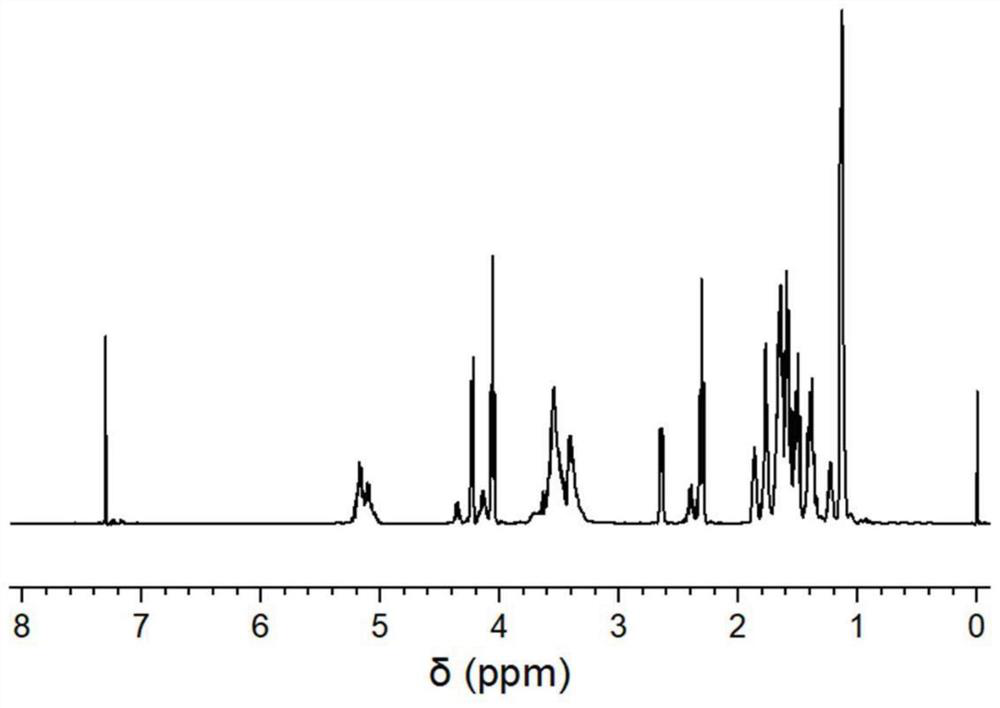

[0044] The preparation method of bio-based polyether ester polyol A1 is as follows:

[0045] Add 150g of thoroughly dried L-lactide, 100g of ε-caprolactone and 100g of short-chain polyether polyol into the reaction kettle, add 0.88g of stannous octoate as the second catalyst, and raise the temperature to 115 under the protection of inert gas. °C, reacted for 24 hours, and then cooled to room temperature to obtain a solid product, namely bio-based polyether ester polyol A1.

Embodiment 2

[0047] The preparation method of bio-based polyether ester polyol A2 is as follows:

[0048] Add 100g of thoroughly dried L-lactide, 150g of ε-caprolactone and 100g of short-chain polyether polyol into the reaction kettle, add 0.88g of stannous octoate as the second catalyst, and raise the temperature to 115 under the protection of inert gas. °C, reacted for 24 hours, and then cooled to room temperature to obtain a solid product, namely bio-based polyether ester polyol A2.

Embodiment 3

[0050] The preparation method of bio-based polyether ester polyol A3 is as follows:

[0051] Add 50g of thoroughly dried L-lactide, 200g of ε-caprolactone and 100g of short-chain polyether polyol into the reaction kettle, add 0.88g of stannous octoate as the second catalyst, and raise the temperature to 115 under the protection of inert gas. °C, reacted for 24 hours, and then cooled to room temperature to obtain a solid product, namely bio-based polyether ester polyol A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com