A heat-insulating poly(p-phenylene terephthalamide)-foam glass sound insulation composite material

A polyparaphenylene terephthalamide and foam glass technology, which is applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of uneven internal pore size, uneven product quality, and foaming process. Instability and other problems, to achieve the effect of effectively absorbing sound waves, enhancing the sound insulation effect, and stabilizing the foaming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

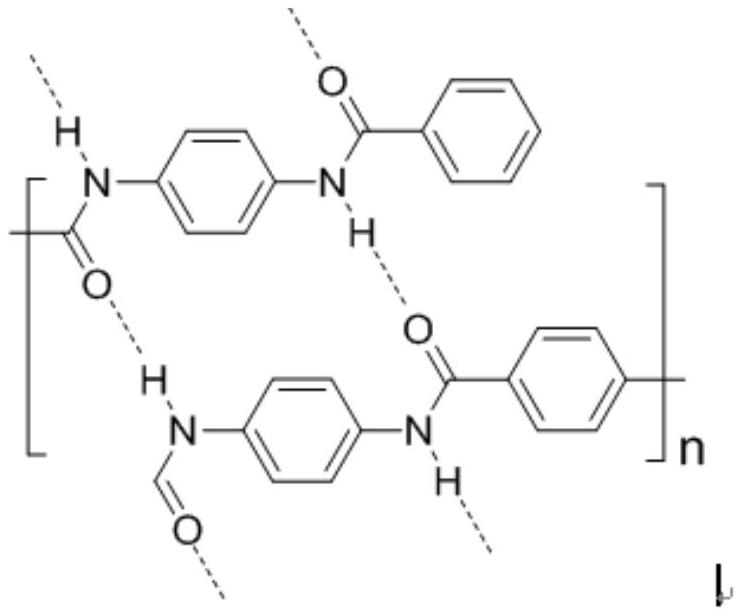

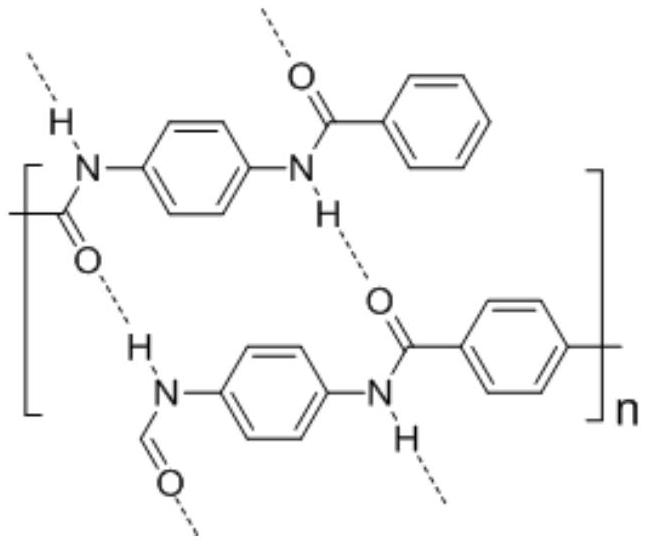

[0028] The foaming aid is potassium hydroxide, in which the content of KOH is 95-98%. Before foaming, KOH and Na 2 B 4 o 5 (OH) 4 ·8H 2 O and SiO in soda lime glass 2 , CaO reaction to produce KNaCaSi 2 o 6 ·6H 2 O crystal, KNaCaSi 2 o 6 ·6H 2 During the heating and foaming process, the O crystal releases steam to make the raw materials foam. This method increases the foaming porosity, and the foaming process is stable. The generated pores are small and evenly distributed, which can effectively absorb sound waves and greatly enhance To ensure the sound insulation effect of foam glass, the foam stabilizer is a mixture of foam stabilizer silicone amide and sodium lauryl sulfate, its mass ratio is 1.5-2:1-1.2, the auxiliary additive is borax, and its main component is 95.4- 98.2% Na 2 B 4 o 5 (OH) 4 ·8H 2 O, the mixed co-solvent is a mixture of ethylene glycol and glycerin, its mass ratio is 3-5:1-1.6, the silane coupling agent is anilinomethyltrimethoxysilane, and...

Embodiment 1

[0035] (1) Anticipation of preparing foam glass: Weigh 70 parts of waste glass slag, 22 parts of waste mineral wool board, 1 part of foaming aid, 0.5 part of foam stabilizer, and 1 part of auxiliary additive in a ball mill and grind for 18-24 hours. Until all the materials pass through the 280-300 mesh sieve, press the obtained expected powder into the mold under the pressure of 10-12MPa, put the obtained sample into the quartz crucible, and put it into the muffle furnace to set the temperature reaction to 260-280 ℃, react for 3-4h, then raise the temperature to the melting temperature of 780-800℃, foam for 2-2.5h, then lower the temperature to 500-550℃, anneal for 30-40min, and finally cool to room temperature Obtaining the foam glass prediction component 1 whose size is 8cm×18cm×5cm;

[0036] (2) Put the foam glass material obtained in the above step (1) into a 2000mL large beaker, add distilled water until the foam glass material is completely immersed, then weigh 2 parts o...

Embodiment 2

[0039] (1) Anticipation of preparing foam glass: Weigh 65 parts of waste glass slag, 22 parts of waste mineral wool board, 2 parts of foaming aid, 1 part of foam stabilizer, and 2 parts of auxiliary additive in a ball mill and grind for 18-24 hours. Until all the materials pass through the 280-300 mesh sieve, press the obtained expected powder into the mold under the pressure of 10-12MPa, put the obtained sample into the quartz crucible, and put it into the muffle furnace to set the temperature reaction to 260-280 ℃, react for 3-4h, then raise the temperature to the melting temperature of 780-800℃, foam for 2-2.5h, then lower the temperature to 500-550℃, anneal for 30-40min, and finally cool to room temperature Obtaining the foam glass prediction component 2 whose size is 8cm×18cm×5cm;

[0040] (2) Place the foam glass material obtained in the above step (1) in a 2000mL beaker, add distilled water until the foam glass material is completely submerged, then weigh 3 parts of mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com