Chemical silver plating and deplating method for surface of ceramic copper-clad substrate

A technology of ceramic copper cladding and substrate surface, applied in the direction of liquid chemical plating, coating, metal material coating process, etc., can solve problems such as troublesome operation, poor adhesion of electroplating layer, over-corrosion of base metal, etc., and achieve saving Production cost, enhanced flame retardancy, effect of improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

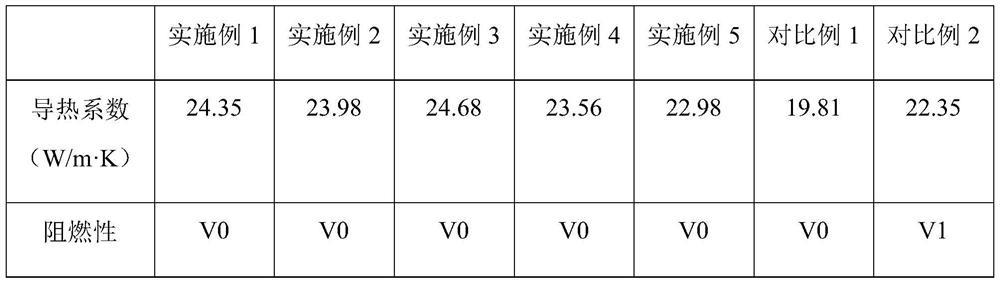

Examples

Embodiment 1

[0033] Embodiment 1: Soak the defective silver-plated product in the deplating solution, and observe the deplating situation.

[0034] Before deplating: the surface of the ceramic copper-clad substrate is a silver-plated layer;

[0035] After deplating: The ceramic copper-clad substrate is restored to the original color of copper, and there is no silver layer residue on the surface, no over-corrosion and blackening of the substrate, and the surface of the ceramic copper-clad substrate is smooth and flat.

Embodiment 2

[0036] Embodiment 2: described preparation process comprises the following steps:

[0037] S1: Take the ceramic copper-clad substrate and plate it with silver;

[0038] S2: Select defective products and perform deplating;

[0039] S3: washing the stripped ceramic copper-clad substrate with water, neutralizing, washing with water again, drying, and preparing for silver plating.

[0040] Described deplating comprises the following steps:

[0041] S1: Configure the deplating solution: mix potassium permanganate, sodium hydroxide, and ammonia water evenly;

[0042] S2: Deplating: immerse the ceramic copper-clad substrate in the deplating solution, and after deplating, inject carbon monoxide into the deplating solution to recover elemental silver;

[0043] S3: ultrasonically treating the stripped ceramic copper-clad substrate for 3 minutes.

[0044] The materials required for the stripping solution in the step S1 include, in terms of concentration: 10 g / L of potassium permangan...

Embodiment 3

[0057] Embodiment 3: described preparation process comprises the following steps:

[0058] S1: Take the ceramic copper-clad substrate and plate it with silver;

[0059] S2: Select defective products and perform deplating;

[0060] S3: washing the stripped ceramic copper-clad substrate with water, neutralizing, washing with water again, drying, and preparing for silver plating.

[0061] Described deplating comprises the following steps:

[0062] S1: Configure the deplating solution: mix potassium permanganate, sodium hydroxide, and ammonia water evenly;

[0063] S2: Deplating: immerse the ceramic copper-clad substrate in the deplating solution, and after deplating, inject carbon monoxide into the deplating solution to recover elemental silver;

[0064] S3: ultrasonically treating the stripped ceramic copper-clad substrate for 3.5 minutes.

[0065] The materials required for the stripping solution in the S1 step include, in terms of concentration: potassium permanganate 11g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com