Creep material and production method thereof

A technology for teaching trough materials and raw materials, applied in the field of teaching trough materials, can solve the problems of easy grading, high processing technology requirements, waste of powder materials, etc., and achieve the effect of improving production performance and improving bargaining power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

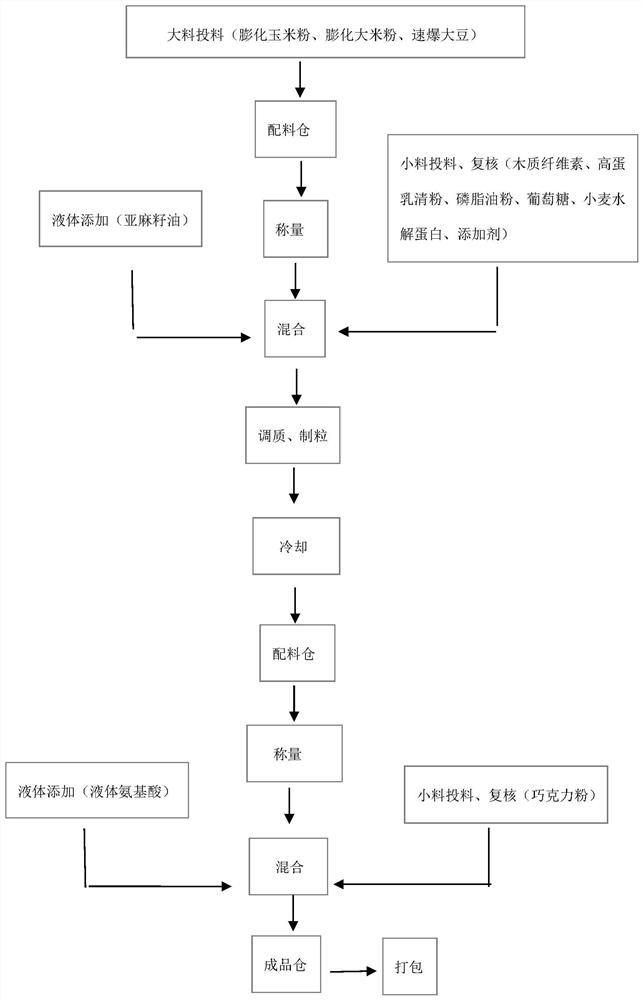

[0035] see figure 1, in the present invention, a kind of creep material comprises following raw materials in parts by weight:

[0036] 250 parts of puffed corn flour, 110 parts of puffed rice flour, 190 parts of instant soybeans, 10 parts of linseed oil, 5 parts of lignocellulose, 90 parts of high egg whey powder, 40 parts of phospholipid oil powder, 70 parts of glucose, hydrolyzed wheat 10 parts of protein, 45 parts of additives, 20 parts of liquid amino acid, 70 parts of chocolate powder.

[0037] The preparation method of the additive in this example is as follows: send the eggshells into a calciner for calcination, the calcination temperature is 300°C, and the calcination time is 10 minutes, and then send them into a 30% mass fraction of sodium alginate solution for ultrasonic dispersion For processing, the ultrasonic power is 100W, the ultrasonic time is 25min, and the ultrasonic is finished, then washed with water and dried to obtain the additive.

[0038] The preparat...

Embodiment 2

[0048] A kind of creep material of the present embodiment comprises following raw materials in parts by weight:

[0049] 260 parts of puffed corn flour, 130 parts of puffed rice flour, 210 parts of instant soybeans, 20 parts of linseed oil, 15 parts of lignocellulose, 110 parts of high egg whey powder, 60 parts of phospholipid oil powder, 80 parts of glucose, hydrolyzed wheat 30 parts of protein, 55 parts of additive, 40 parts of liquid amino acid, 80 parts of chocolate powder.

[0050] The preparation method of the additive in this example is as follows: put the eggshell into a calciner for calcination, the calcination temperature is 400°C, the calcination time is 20min, and then send it into a 30% mass fraction of sodium alginate solution for ultrasonic dispersion For processing, the ultrasonic power is 500W, the ultrasonic time is 35min, and the ultrasonic is finished, then washed with water and dried to obtain the additive.

[0051] The preparation method of the liquid am...

Embodiment 3

[0061] A kind of creep material of the present embodiment comprises following raw materials in parts by weight:

[0062] 255 parts of puffed corn flour, 120 parts of puffed rice flour, 200 parts of instant soybeans, 15 parts of linseed oil, 10 parts of lignocellulose, 100 parts of high egg whey powder, 50 parts of phospholipid oil powder, 75 parts of glucose, hydrolyzed wheat 20 parts of protein, 50 parts of additive, 30 parts of liquid amino acid, 75 parts of chocolate powder.

[0063] The preparation method of the additive in this example is as follows: send the eggshell into a calciner for calcination, the calcination temperature is 350°C, and the calcination time is 15 minutes, and then send it into a sodium alginate solution with a mass fraction of 30% for ultrasonic dispersion For processing, the ultrasonic power is 30W, the ultrasonic time is 30min, and the ultrasonic is finished, then washed with water and dried to obtain the additive.

[0064] The preparation method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com