Production process of coated nut kernels

A production process, the technology of nut kernels, applied in the field of food processing, to achieve the effect of improving anti-oxidation, large contact area and uniform baking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

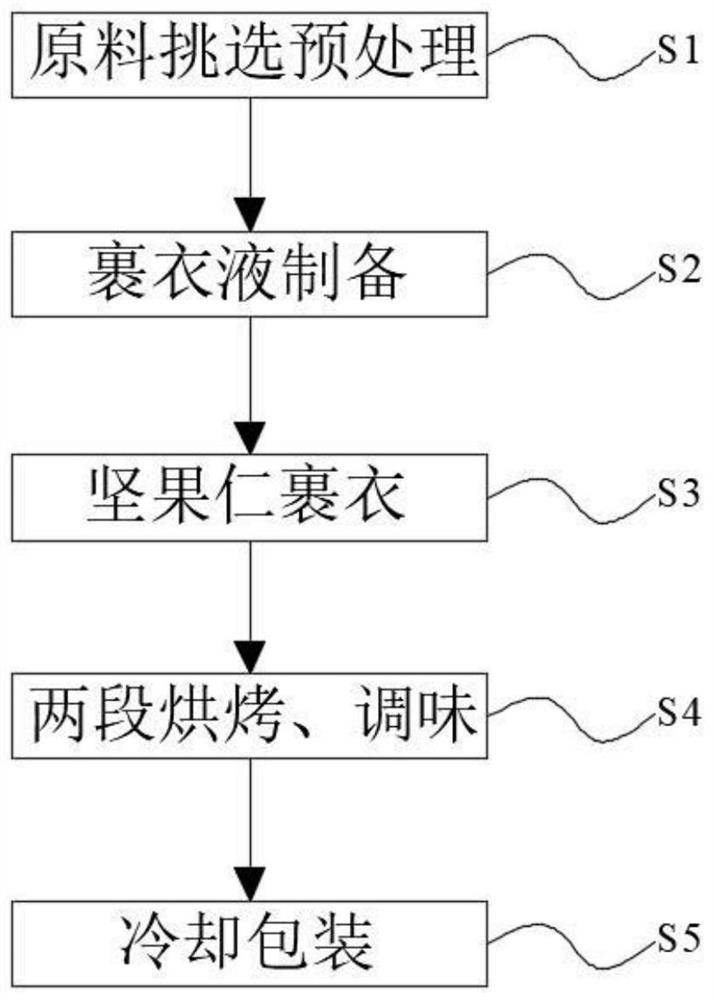

[0039] Such as Figure 1-8 Shown, a kind of production technology of coated nut kernel of the present embodiment comprises the following steps:

[0040] S1. Raw material selection and pretreatment: select nut varieties with full grains and no pests and diseases, wash and dry, remove the shell, and obtain nut kernels. Among them, the drying temperature is 110-115°C, and the drying time is 40-55 minutes; the nuts are selected from pecan kernels, pistachio kernels, cashew kernels, walnut kernels, almond kernels, macadamia nuts, and hazelnut kernels. one or a combination of more.

[0041] S2. Preparation of coating liquid: mix and dissolve flour, water, sugar, butylated hydroxyanisole according to the mass ratio of 8-15:120-140:25-35:1-3, boil over low heat until 120-130°C, Get a coat. Among them, the flour is made by mixing wheat flour and potato starch in a mass ratio of 3-5:1; the sugar is made by mixing white granulated sugar and maltose in a mass ratio of 6-8:1.

[0042] S3...

Embodiment 2

[0052] Such as figure 1 Shown, a kind of production technology of coated nut kernel of the present embodiment comprises the following steps:

[0053] S1. Raw material selection and pretreatment: select nut varieties with full grains and no pests and diseases, wash and dry, remove the shell, and obtain nut kernels. Wherein, the drying temperature is 112° C., and the drying time is 50 minutes; the nut variety is selected from cashew kernels.

[0054] S2. Preparation of coating solution: flour, water, sugar, and butyl hydroxyanisole were mixed and dissolved in a mass ratio of 12:130:28:1.6, boiled over low heat to 126°C to obtain a coating solution. Among them, the flour is made by mixing wheat flour and potato starch in a mass ratio of 4.2:1; the sugar is made by mixing white granulated sugar and maltose in a mass ratio of 7:1.

[0055] S3. Wrapping the nut kernels: use an automatic wrapping machine to wrap the surface of the nut kernels with a coating solution to obtain a sem...

Embodiment 3

[0059] Such as figure 1 Shown, a kind of production technology of coated nut kernel of the present embodiment comprises the following steps:

[0060] S1. Raw material selection and pretreatment: select nut varieties with full grains and no pests and diseases, wash and dry, remove the shell, and obtain nut kernels. Wherein, the drying temperature is 115° C., and the drying time is 42 minutes; the nut variety is selected from walnut kernels.

[0061] S2. Preparation of coating solution: flour, water, sugar, and butyl hydroxyanisole were mixed and dissolved in a mass ratio of 12:135:32:2.5, boiled over low heat to 126°C to obtain a coating solution. Among them, the flour is made by mixing wheat flour and potato starch in a mass ratio of 4.2:1; the sugar is made by mixing white granulated sugar and maltose in a mass ratio of 6.5:1.

[0062] S3. Wrapping the nut kernels: use an automatic wrapping machine to wrap the surface of the nut kernels with a coating solution to obtain a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com