Composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane and support layer technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of high calcium chloride retention rate, improve water flux, good application prospects, high Electronegativity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

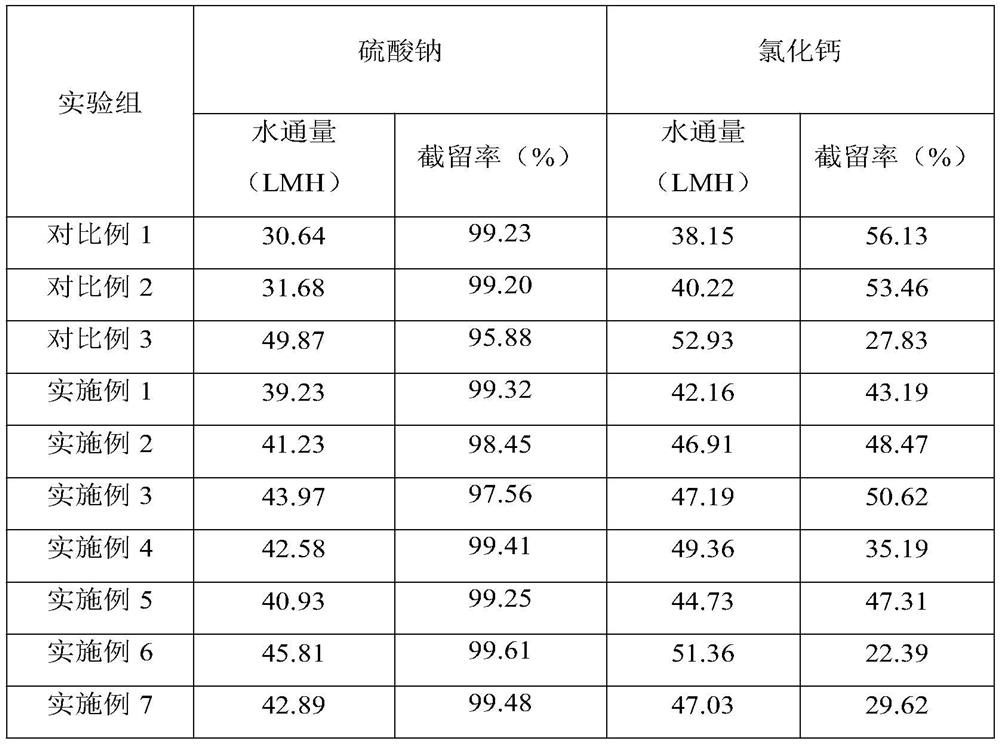

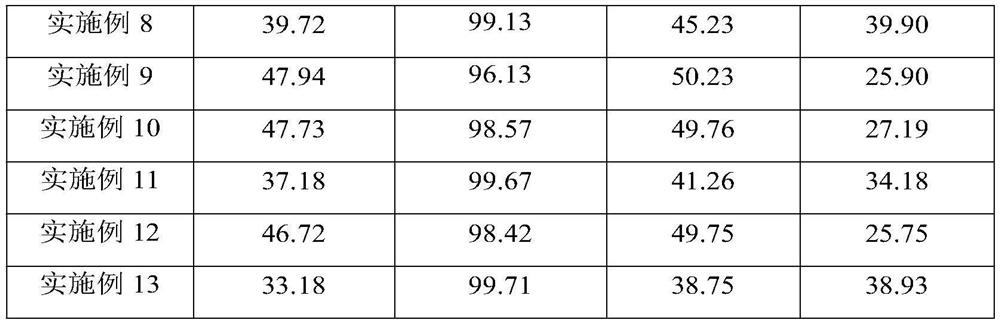

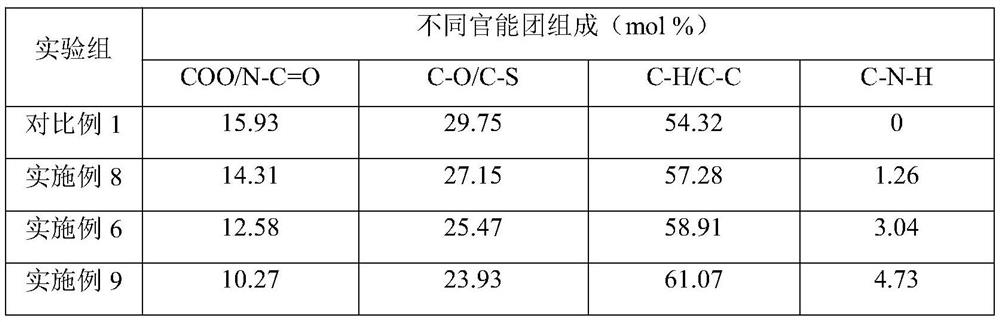

Examples

Embodiment 1

[0027] A composite nanofiltration membrane comprising a support layer and a polyamide functional layer arranged on the support layer, the polyamide functional layer comprising the following raw material components: polyamine, water phase additive, polyacyl chloride, oil phase solvent and deionized Water; the water phase additive is hydroxylamine-O-sulfonic acid.

[0028] The polyamine is piperazine.

[0029] The polybasic acid chloride is trimesoyl chloride.

[0030] The oil phase solvent is n-hexane.

[0031] The support layer includes a base layer and a porous ultrafiltration layer arranged on the base layer, and the base layer (specifically, non-woven fabric) adopts a polyester raw material component; the porous ultrafiltration layer adopts a raw material component For polyethersulfone.

[0032] The specific preparation process of the support layer is as follows: Weigh 75g of polyethersulfone (PES) and 425g of N-methylpyrrolidone (NMP), mix and prepare a 500g solution, s...

Embodiment 2

[0043] The difference from Example 1 is that the polyamine is 1,6-hexanediamine.

Embodiment 3

[0045] The difference from Example 1 is that the polyamine is 1,4-diaminocyclohexane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com