Wiring device of single-line slicing machine

A wiring device and slicer technology, applied in the direction of grinding drive device, fine working device, grinding machine tool parts, etc., can solve the problems of low cutting efficiency, high clamping degree of strip steel strip, high cost of processing materials, etc. , to achieve the effect of simplifying the overall structure, improving cutting efficiency, and convenient control and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

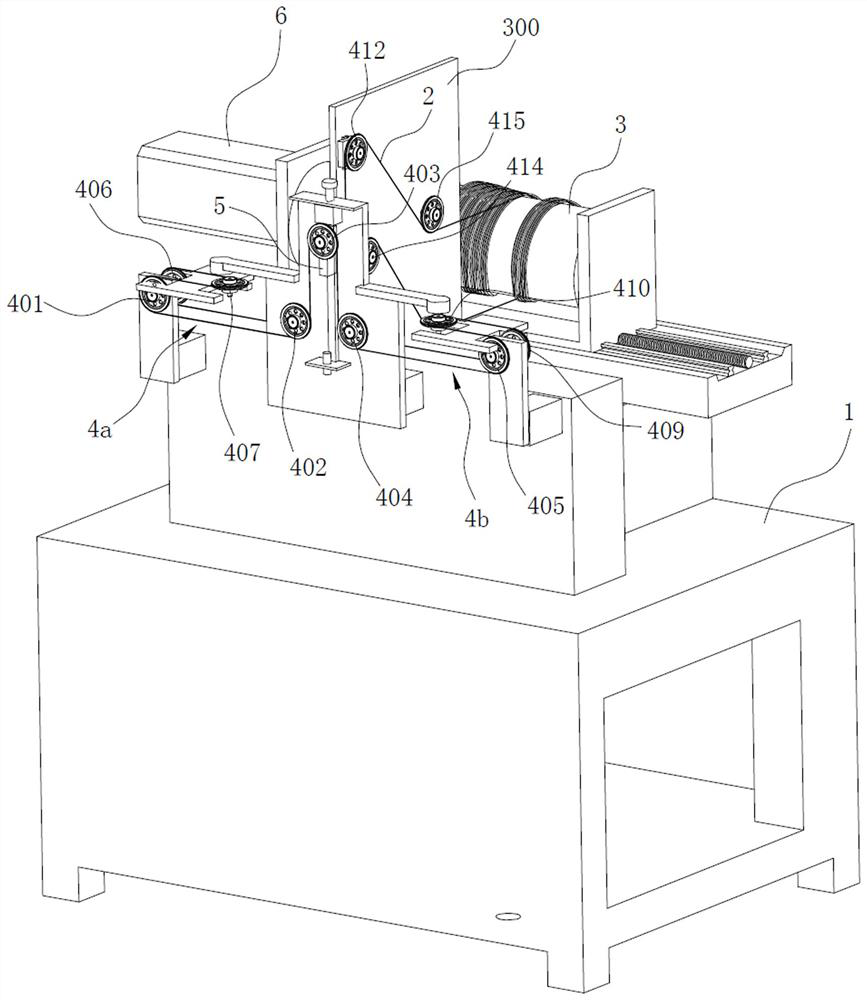

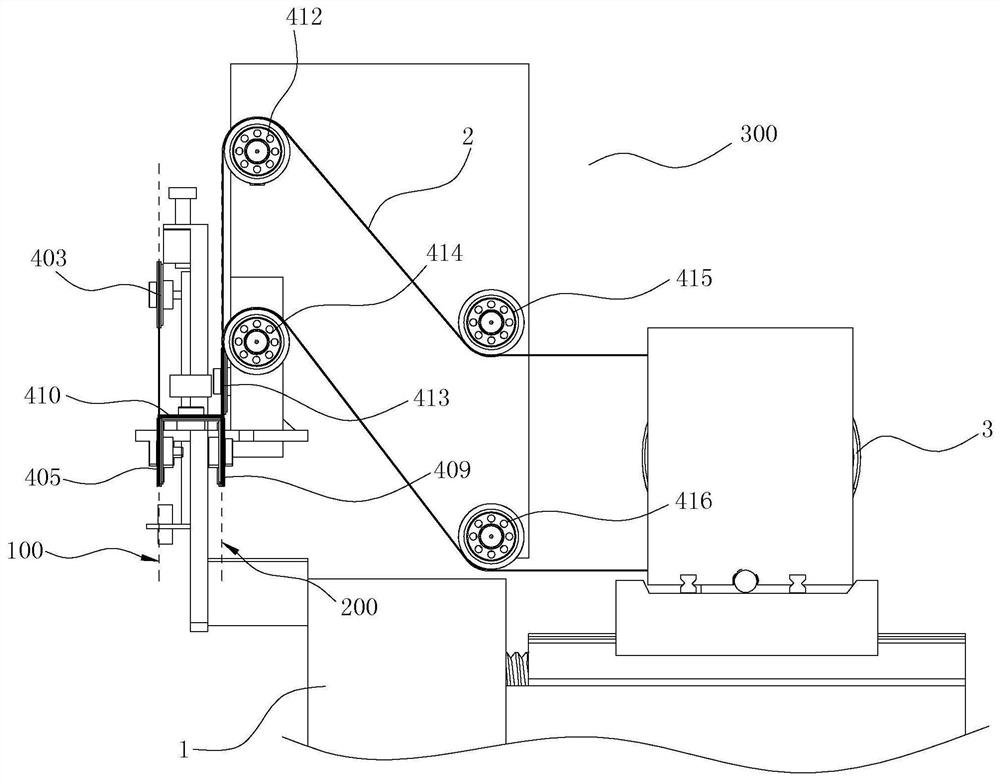

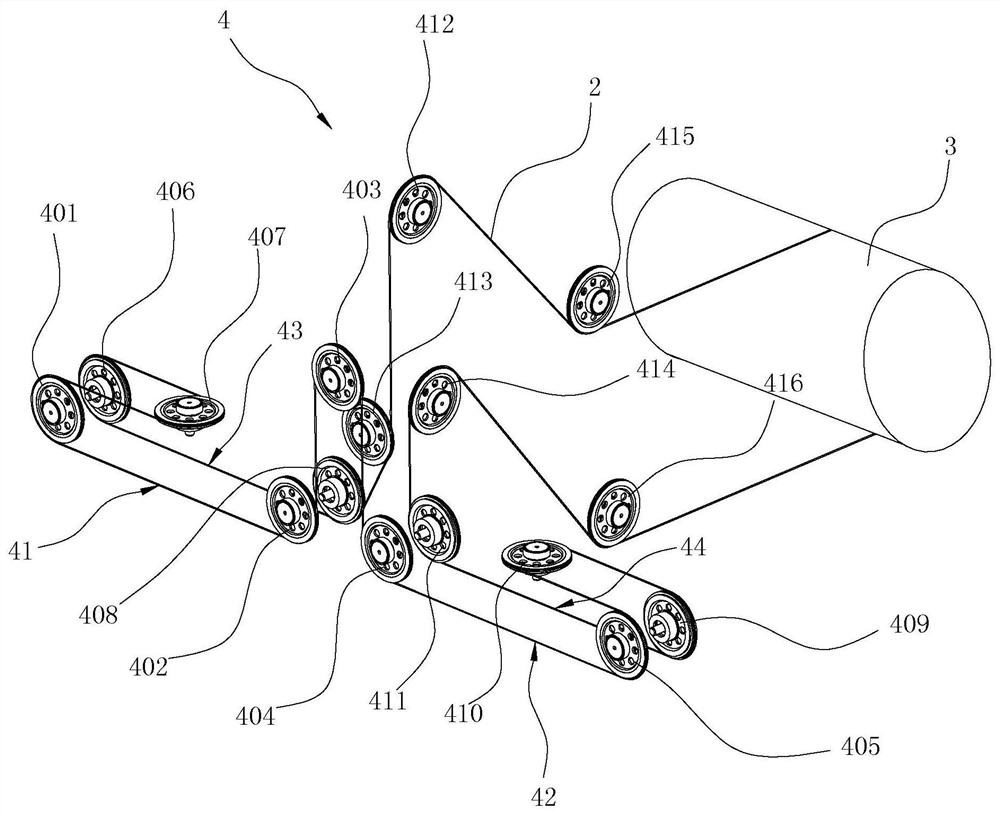

[0034] like Figure 1~4 As shown, the single wire slicer wiring device of this embodiment includes a cutting wire 2 and a guide wheel assembly 4 . Wherein, the cutting wire 2 is used for cutting materials, and the cutting wire 2 is wound on a drum 3. The cutting wire 2 in this embodiment adopts a diamond wire, but of course the cutting wire is not limited to a diamond wire. The drum 3 is rotatably arranged on the rear side of the frame 1, and the drum 3 is horizontally arranged left and right. The upper side of the drum 3 is the first winding side, and the lower side of the drum 3 is the second winding side, and the first winding side and the second winding side are in the same state as the winding state and the returning wire as the rotation direction of the drum 3 changes. Toggle between states. For example, when the drum 3 rotates in one direction, the upper side of the drum 3 is the line side of the cutting line 2, and the lower side of the drum 3 is the side of the cutt...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 lies in that the setting positions of the seventh guide wheel and the tenth guide wheel are different.

[0047] like Figure 5 As shown, the seventh guide wheel 407' is arranged above the first guide wheel 401 and the sixth guide wheel 406. Corresponding, its front edge corresponds to the outer edge of the first guide wheel 401; the tenth guide wheel 410' is located above the fifth guide wheel 405 and the ninth guide wheel 409, and the axis line of the tenth guide wheel 410' is arranged horizontally And its rear edge corresponds to the outer edge of the ninth guide wheel 409 , and its front edge corresponds to the outer edge of the fifth guide wheel 405 . The first end of the cutting line 2 is arranged around the outer edge of the first guide wheel 401, the upper edge of the seventh guide wheel 407', the outer edge of the sixth guide wheel 406, and the lower edge of the eighth guide wheel 408 from front to back. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com