Index gradient acoustic covering layer with embedded scatterers and cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

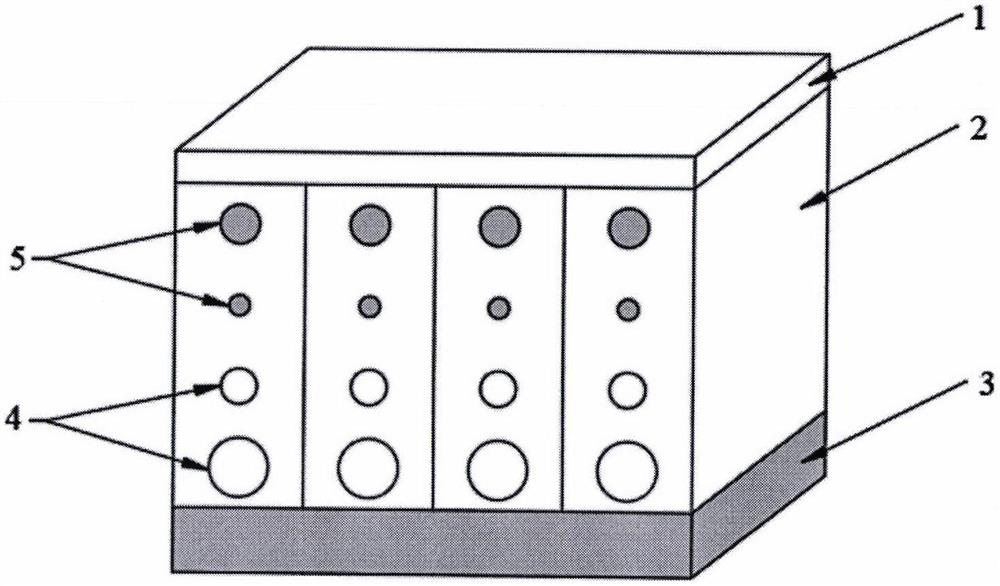

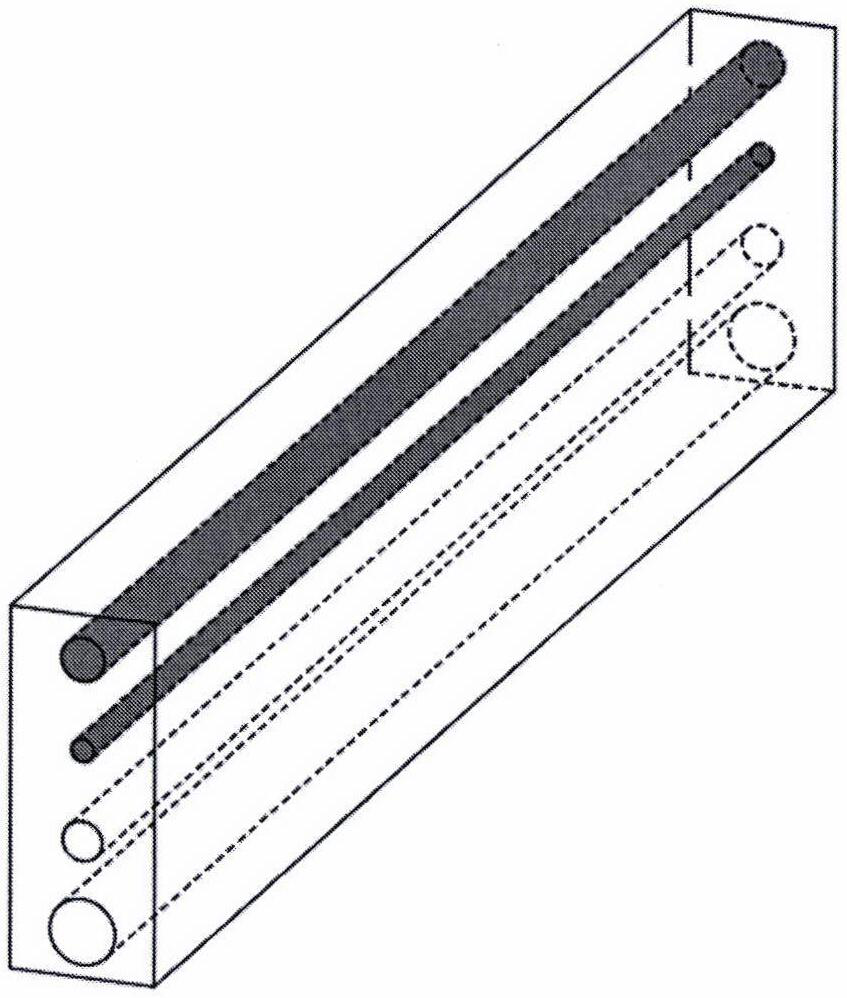

Image

Examples

Embodiment 1

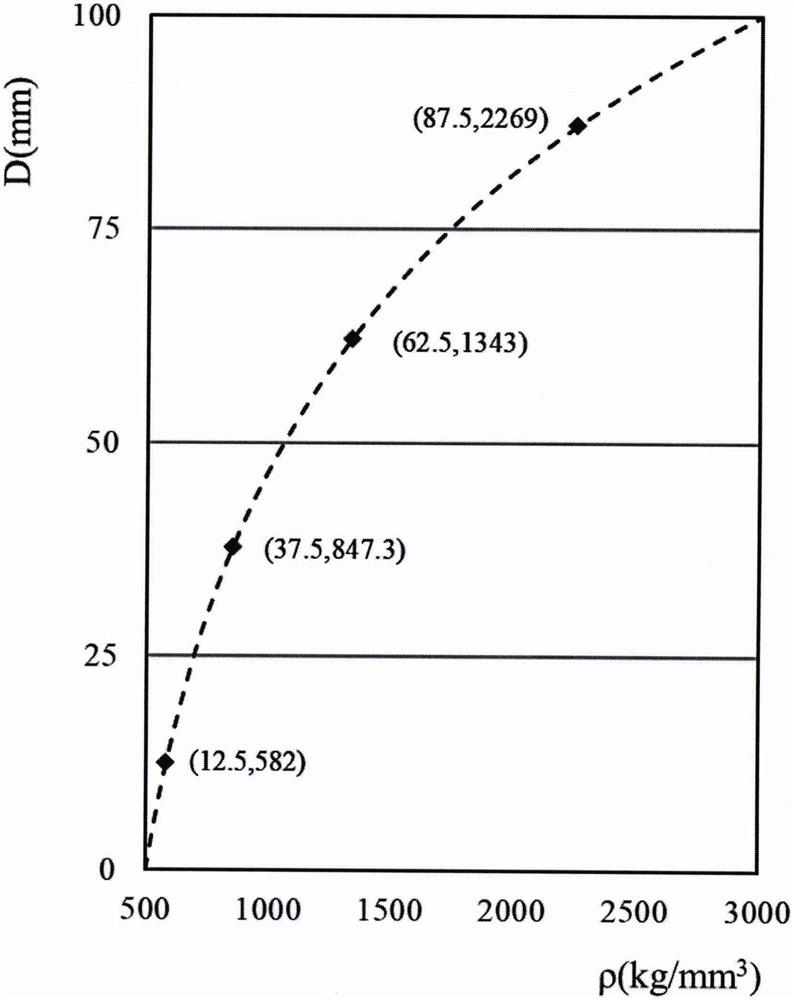

[0029] Each sound-absorbing layer unit is divided into 4 layers with equal thickness, and the layering method is as follows: image 3 As shown, the specific equivalent density is in image 3 Marked out. The equivalent densities of the four layers of media selected along the y-axis are 582kg / m3 、847.3kg / m 3 、1343kg / m 3 、2269kg / m 3 , the embedded structure radii to the 4-layer medium calculated by the homogenization method are 9.12mm (cavity), 5.51mm (cavity), 3.15mm (steel cylinder), 6.05mm (steel cylinder) from bottom to top. The distance between the center of the scatterer and the cavity in each unit is c=25mm, and the distance between the center of the scatterer on the first layer and the cavity on the fourth layer is d from the top and bottom 1 =12.5mm, distance from both ends is d 2 = 12.5 mm. Figure 5 The sound absorption coefficient curves of the gradient medium acoustic covering layer and the homogeneous medium acoustic covering layer of the present invention are...

Embodiment 2

[0031] Different from Example 1, in Example 2, the sound-absorbing layer is divided into 5 layers with equal thickness, and the layering method is the same as that in Example 1. The equivalent densities of the five layers of media selected along the y-axis are 564kg / m 3 、749.7kg / m 3 、1056.8kg / m 3 、1563kg / m 3 、2397.5kg / m 3 , the embedded structure radii to the 5-layer media calculated by the homogenization method are 8.33mm (cavity), 6.31mm (cavity), 1.15mm (steel cylinder), 3.61mm (steel cylinder), and 5.68mm (steel cylinder). The distance between the center of the scatterer and the cavity in each unit is c=20mm, and the distance between the center of the scatterer on the first layer and the cavity on the fourth layer is d from the top and bottom 1 =10mm, the distance between both ends is d 2 = 12.5 mm. Figure 5 The sound absorption coefficient curves of the gradient medium acoustic covering layer and the homogeneous medium acoustic covering layer of the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com