Phase inversion method for preparing silicon nitride ceramic material with fiber monolithic structure

A technology of silicon nitride ceramics and phase inversion method, which is applied in the direction of ceramic forming machines and manufacturing tools, can solve the problems of low fracture toughness, achieve high production efficiency, facilitate subsequent arrangement, and overcome the effects of low fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

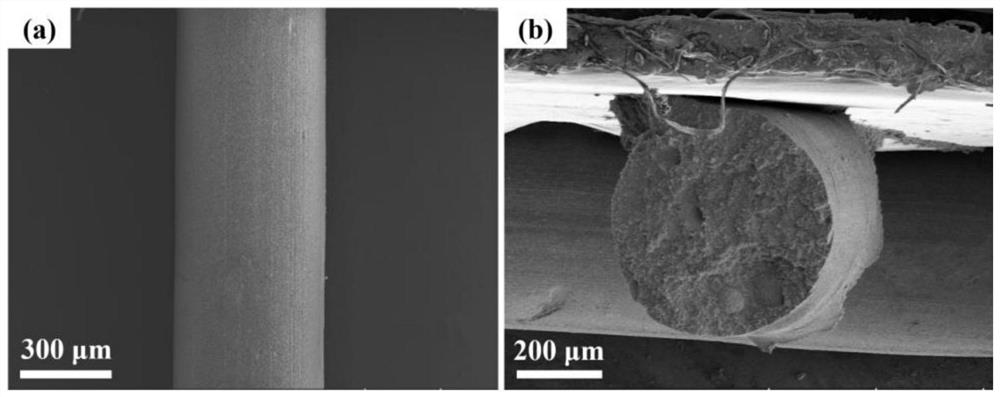

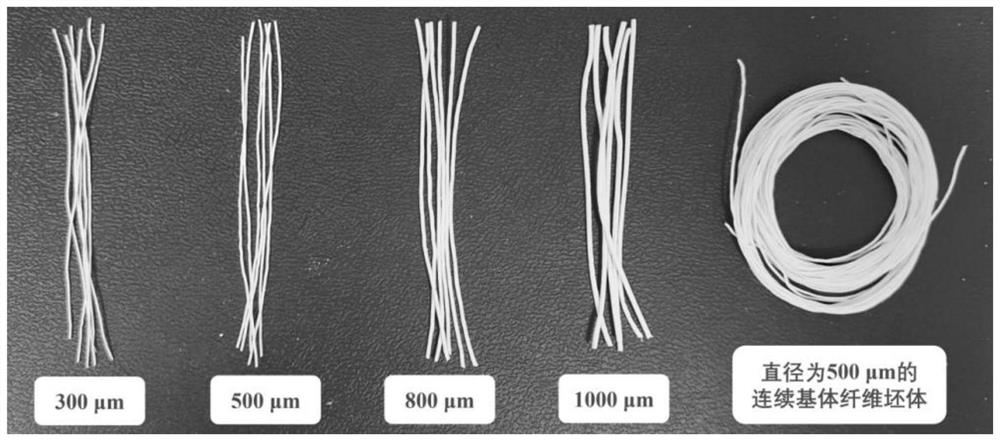

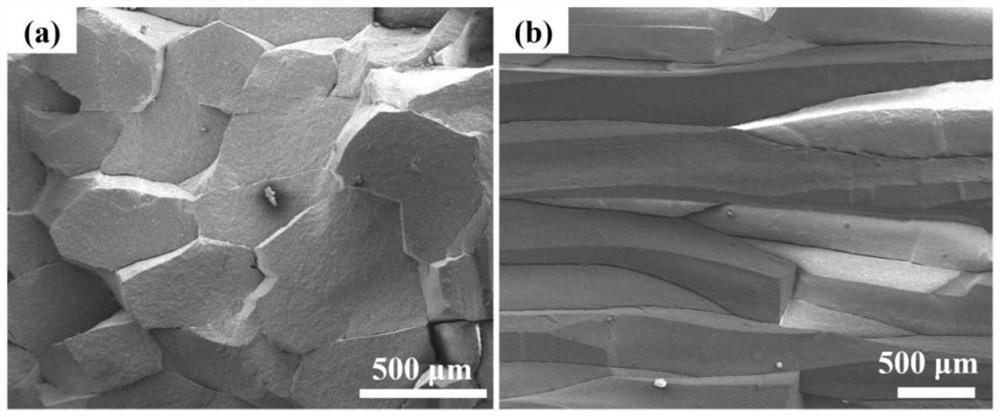

[0033] Example 1 A preparation method of fiber monolithic silicon nitride ceramics prepared by a phase inversion method

[0034] The method includes the following steps:

[0035] (1) Weigh 65wt.% of Si 3 N 4 powder, 25wt.% BN powder and 10wt.% sintering aid 【Y 2 o 3 +Al 2 o 3 ,m(Y 2 o 3 ): m(Al 2 o 3 )=2], using a planetary ball mill for wet ball milling for 18 hours at a speed of 200r / min, then drying in an oven at 70°C, and passing the dried ceramic powder through a 100-mesh sieve for use.

[0036] (2) Use polyethersulfone (PES) as the polymer matrix binder, N-methylpyrrolidone (NMP) as the solvent, add a certain amount of PES into the NMP, stir until it is completely dissolved, as a polymer solution, The concentration of the polymer solution was 0.10 g / mL.

[0037] (3) 20wt.% rare earth silicate Yb 2 Si 2 o 7 The powder, 2wt.% methylcellulose binder and deionized water or alcohol were ball milled for 18 hours at a rotation speed of 260r / min to obtain a rare eart...

Embodiment 2

[0046] Example 2 A preparation method of fiber monolithic silicon nitride ceramics prepared by a phase inversion method

[0047] The method includes the following steps:

[0048] (1) Weigh 70wt.% Si 3 N 4 powder, 10wt.% BN powder and 20wt.% sintering aid 【Y 2 o 3 +Al 2 o 3 ,m(Y 2 o 3 ): m(Al 2 o 3 )=3], using a planetary ball mill for wet ball milling for 24 hours at a speed of 100r / min, and then drying in an oven at 100°C, and passing the dried ceramic powder through a 200-mesh sieve for use.

[0049] (2) Use polyethersulfone (PES) as the polymer matrix binder, N-methylpyrrolidone (NMP) as the solvent, add a certain amount of PES into the NMP, stir until it is completely dissolved, as a polymer solution, The concentration of the polymer solution was 0.25 g / mL.

[0050] (3) 5wt.% rare earth silicate powder Y 2 SiO 5 +Yb 2 Si 2 o 7 (where Y 2 SiO 5 and Yb 2 Si 2 o 7 The mass ratio is 1:1) and 5wt.% of methylcellulose binder and deionized water or alcohol ba...

Embodiment 3

[0056] Example 3 A preparation method for preparing fiber monolithic silicon nitride ceramics by a phase inversion method

[0057] The method includes the following steps:

[0058] (1) Weigh 48wt.% of Si 3 N 4 powder, 45wt.% BN powder and 15wt.% sintering aid 【Y 2 o 3 +Al 2 o 3 ,m(Y 2 o 3 ): m(Al 2 o 3 )=1.5], using a planetary ball mill for wet ball milling for 6 hours at a speed of 360r / min, then drying in an oven at 50°C, and passing the dried ceramic powder through a 40-mesh sieve for use.

[0059] (2) Use polyethersulfone (PES) as the polymer matrix binder, N-methylpyrrolidone (NMP) as the solvent, add a certain amount of PES into the NMP, stir until it is completely dissolved, as a polymer solution, The concentration of the polymer solution was 0.05 g / mL.

[0060] (3) 10wt.% rare earth silicate powder Ho 2 SiO 5 +Lu 2 SiO+Er 2 SiO 5 (The mass ratio of the three is 1:1:

[0061] 1) and 0.5wt.% methylcellulose binder and deionized water or alcohol ball mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com