Preparation method of composite microporous multi-structure bionic artificial bone, and gradient mold

A multi-structure, artificial bone technology, applied in molds, home appliances, tissue regeneration, etc., to achieve controllable porosity, controllable channel distribution, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

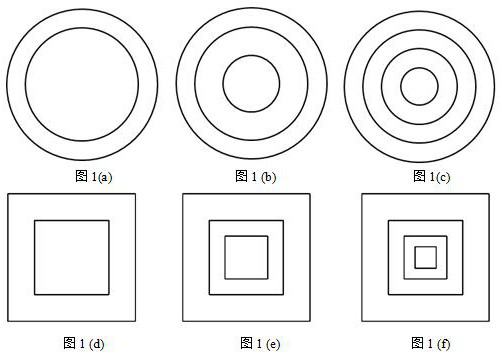

[0044] The preparation method of the composite microporous multi-structure bionic artificial bone comprises the following steps:

[0045] Step 1, the preparation of the mixed powder in the inner layer, uniformly mix the pore forming agent with a content of 30wt% (porosity 30wt%) and the ceramic powder with a content of 70wt%;

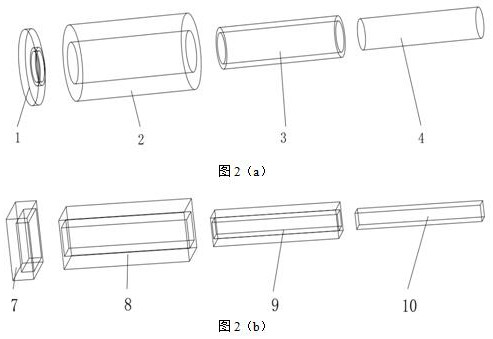

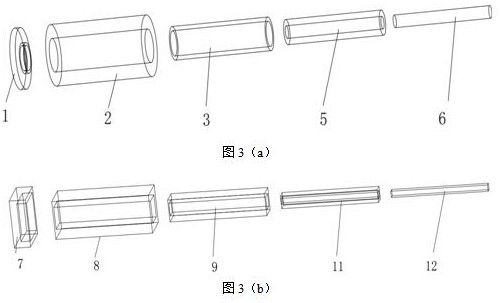

[0046] Step 2, preparation of the complex: fix the sleeve and the inner layer indenter in the two-layer gradient structure mold to the chassis, and the annular space reserved between the sleeve and the inner layer indenter is a two-layer gradient structure The size of the outer layer; fill the annular space with the powder material required for the design, and lightly press it with the outer layer pressure head; then pull out the inner layer pressure head gently, and the inner layer pressure head is pulled out. The space vacated (after the inner layer pressing head is taken out, the original position of the inner layer pressing head will be free to add ...

Embodiment 2

[0054] The preparation method of the composite microporous multi-structure bionic artificial bone comprises the following steps:

[0055] Step 1, the preparation of the mixed powder in the inner layer, uniformly mix the pore former (50% porosity) with a content of 50wt% and the ceramic powder with a content of 50wt%;

[0056] Step 2, preparation of the complex: fix the sleeve and the inner layer indenter in the two-layer gradient structure mold to the chassis, and the annular space reserved between the sleeve and the inner layer indenter is a two-layer gradient structure The size of the outer layer; fill the annular space with the powder material required for the design, and lightly press it with the outer layer pressure head; then pull out the inner layer pressure head gently, and the inner layer pressure head is pulled out. The space vacated (after the inner layer pressing head is taken out, the original position of the inner layer pressing head will be free to add powder) i...

Embodiment 3

[0064] The preparation method of the composite microporous multi-structure bionic artificial bone comprises the following steps:

[0065] Step 1, the preparation of the mixed powder in the inner layer, uniformly mix the pore forming agent with a content of 70wt% (porosity of 70%) and the ceramic powder with a content of 30wt%;

[0066] Step 2, preparation of the complex: fix the sleeve and the inner layer indenter in the two-layer gradient structure mold to the chassis, and the annular space reserved between the sleeve and the inner layer indenter is a two-layer gradient structure The size of the outer layer; fill the annular space with the powder material required for the design, and lightly press it with the outer layer pressure head; then pull out the inner layer pressure head gently, and the inner layer pressure head is pulled out. Fill the vacated space with the powder material required for the design, and insert the inner layer pressing head again;

[0067] Step 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com