Photo-thermal driven shape memory nano composite material as well as preparation method and application thereof

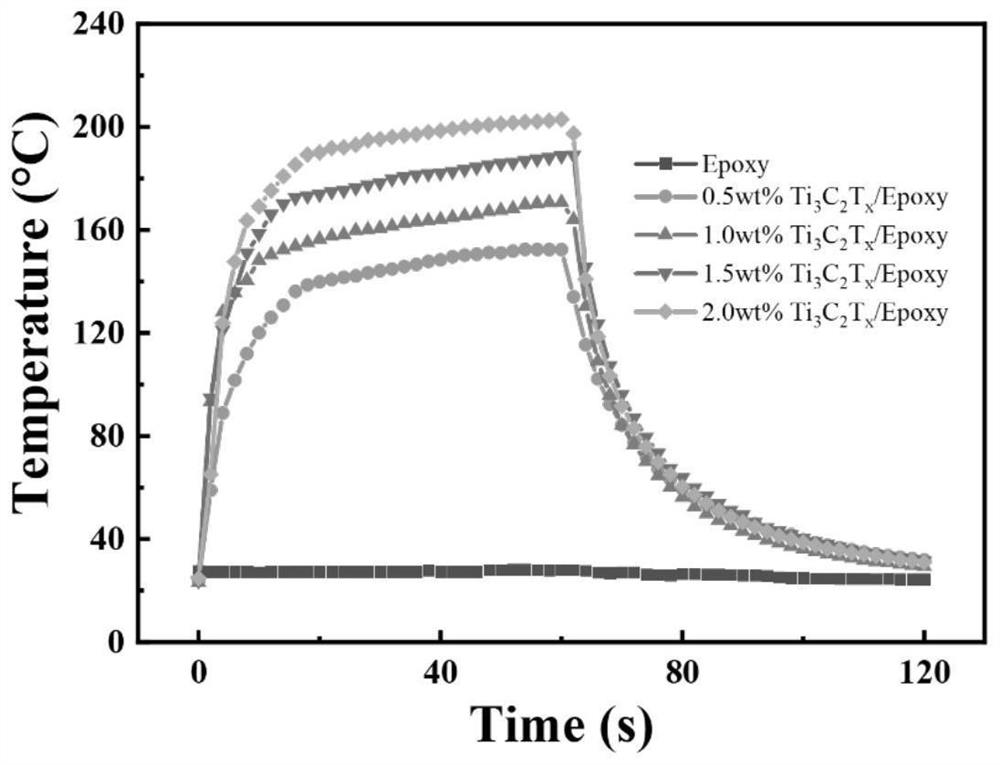

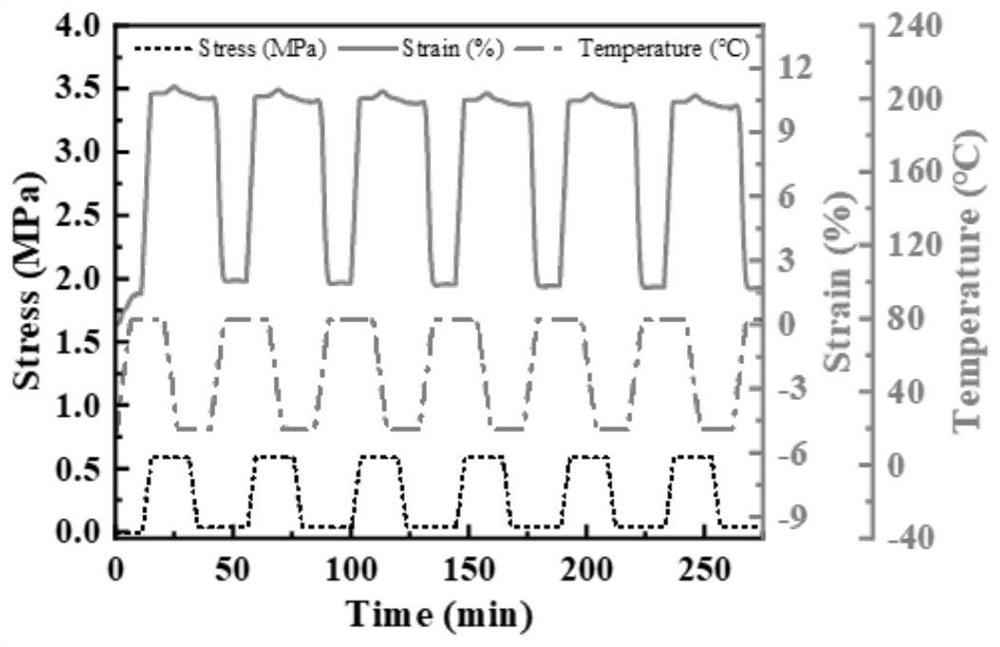

A technology of nanocomposite materials and nanofillers, which is applied in the field of photothermally driven shape memory nanocomposites and its preparation, can solve the problems of reduced shape memory performance of composite materials, low photothermal conversion efficiency, and poor dispersion of fillers, etc., to achieve stability Shape memory properties, beneficial light absorption and heat diffusion, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the shape-memory nanocomposite of the present embodiment comprises the following steps:

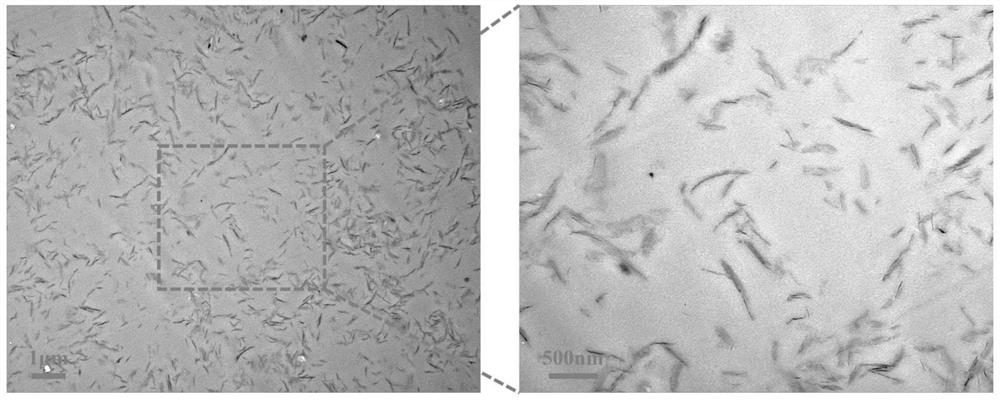

[0035] (1) Ti 3 C 2 T x Preparation of nanosheet solutions

[0036] Dissolve 1.6g LiF powder in 20mL HCl solution with a concentration of 9M, stir magnetically for 10min, and slowly add 1gTi 3 AlC 2 powder, to prevent overheating of the reaction, and then magnetically stirred for 30 hours in a water bath at 35°C, repeatedly washed with deionized water, oscillated, and centrifuged at 7500rpm for 5min, centrifuged 7-10 times until the pH of the supernatant was > 7; Sonicate in a water bath for 120min, then centrifuge the solution at 3500rpm for 30min, take the black supernatant after centrifugation as Ti 3 C 2 T x nanosheet solution.

[0037] (2) Preparation of shape memory nanocomposites

[0038] Take 50mL of Ti with a concentration of 5mg / mL 3 C 2 T x Add the nanosheet solution to 20 g of water-based epoxy resin with a solid content of 50%, magne...

Embodiment 2

[0045] The preparation method of the shape-memory nanocomposite of the present embodiment comprises the following steps:

[0046] (1) Ti 3 C 2 T x Preparation of nanosheet solutions

[0047] Ti in this example 3 C 2 T x The preparation of nanoplatelet solution and Ti in embodiment 1 3 C 2 T x Nanosheets were prepared in the same way.

[0048] (2) Preparation of shape memory nanocomposites

[0049] Take 38mL of Ti with a concentration of 5mg / mL 3 C 2 T x Add the nanosheet solution to 20 g of water-based epoxy resin with a solid content of 50%, magnetically stir for 15 minutes and then ultrasonically treat it for 30 minutes, then add 5 g of water-based amine-based curing agent with a solid content of 50%, stir magnetically for 15 minutes, and then place the mixture in- Freeze-dry at 15~-25°C for 120h, take the dried powder and hot-press for 2h at a temperature of 120°C and a pressure of 10MPa to obtain 1.5wt% Ti with optically driven shape memory properties 3 C 2 ...

Embodiment 3

[0054] The preparation method of the shape-memory nanocomposite of the present embodiment comprises the following steps:

[0055] (1) Ti 3 C 2 T x Preparation of nanosheet solutions

[0056] Ti in this example 3 C 2 T x The preparation of nanoplatelet solution and Ti in embodiment 1 3 C 2 T x Nanosheets were prepared in the same way.

[0057] (2) Preparation of shape memory nanocomposites

[0058] Take 25mL of Ti with a concentration of 5mg / mL 3 C 2 T x Add the nanosheet solution to 20 g of water-based epoxy resin with a solid content of 50%, magnetically stir for 15 minutes and then ultrasonically treat it for 30 minutes, then add 5 g of water-based amine-based curing agent with a solid content of 50%, stir magnetically for 15 minutes, and then place the mixture in- Freeze-dry at 15°C to -25°C for 120h, take the dried powder and hot-press for 2h at a temperature of 120°C and a pressure of 10MPa to obtain 1wt% Ti with optically driven shape memory properties 3 C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com