Modified ferroferric oxide particles and preparation method and application thereof, modified ferroferric oxide/epoxy composite coating and application thereof

A kind of iron tetroxide, modified technology, applied in epoxy resin coatings, chemical instruments and methods, anti-corrosion coatings, etc., can solve problems such as poor mechanical properties and anti-corrosion properties, hindering the penetration of corrosive media, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a method of preparing the modified tetrashydoxide particles described above, including the following steps:

[0032] Put Fe 3 O 4 The dispersion and the silane coupling aqueous solution are mixed, and the grafting reaction is performed under conditions having a pH of 3 to 4 to obtain intermediate Fe. 3 O4 ;

[0033] Will the intermediate Fe 3 O 4 The dispersion, initiator and methacrylate mixture were mixed, and the polymerization reaction was carried out to obtain a modified tetracted three iron particles.

[0034] In the present invention, the raw materials used are commercially available goods well known in the art without special instructions.

[0035] The present invention will Fe 3 O 4 The dispersion and the silane coupling aqueous solution are mixed, and the grafting reaction is performed under conditions having a pH of 3 to 4 to obtain intermediate Fe. 3 O 4 .

[0036] In the present invention, the Fe 3 O 4 The dispersion used in the d...

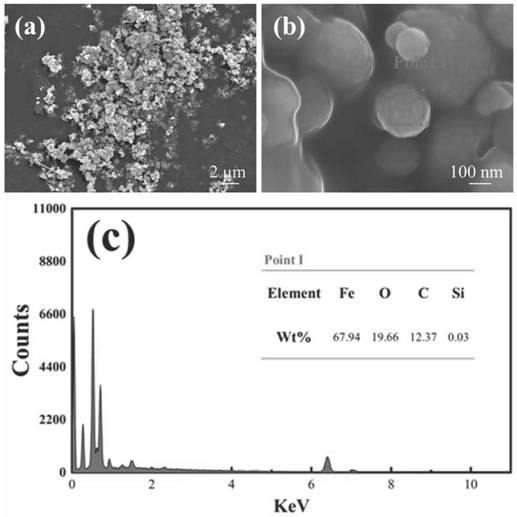

Embodiment 1

[0065] Take 2G Fe 3 O 4 Disperse in 400 ml of unhappy ethanol, ultrasonic 1h get Fe 3O 4 Dispersion; take 4.5 g of silane coupling agent KH570 and 0.5 g of deionized water to be configured as a silane coupling agent aqueous solution, will Fe 3 O 4 The dispersion and the silane coupling aqueous solution mixed, mechanically stirred at a pH of 3 to 4, 80 ° C for grafting reaction, resulting in an intermediate Fe 3 O 4 , Remember K-Fe 3 O 4 Take 0.5g k-Fe 3 O 4 After dispersion of 400 ml of anhydrous ethanol, 0.1 gAibn was added, and the mixture was mechanically stirred at 80 ° C, and 5 g gmaa was slowly added dropwise, and the mixture was continued at 80 ° C for 8 h at 80 ° C for G-Fe. 3 O 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com