Heat preservation and insulation coating, preparation method of heat preservation and insulation coating and heat preservation and insulation coating layer

A thermal insulation and coating technology, applied in the field of coatings, can solve the problems of reducing the mechanical properties of the coating, the weak binding force between the surface and the polymer film-forming material, etc., and achieve the improvement of adhesion, impact resistance, mechanical properties, and The effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

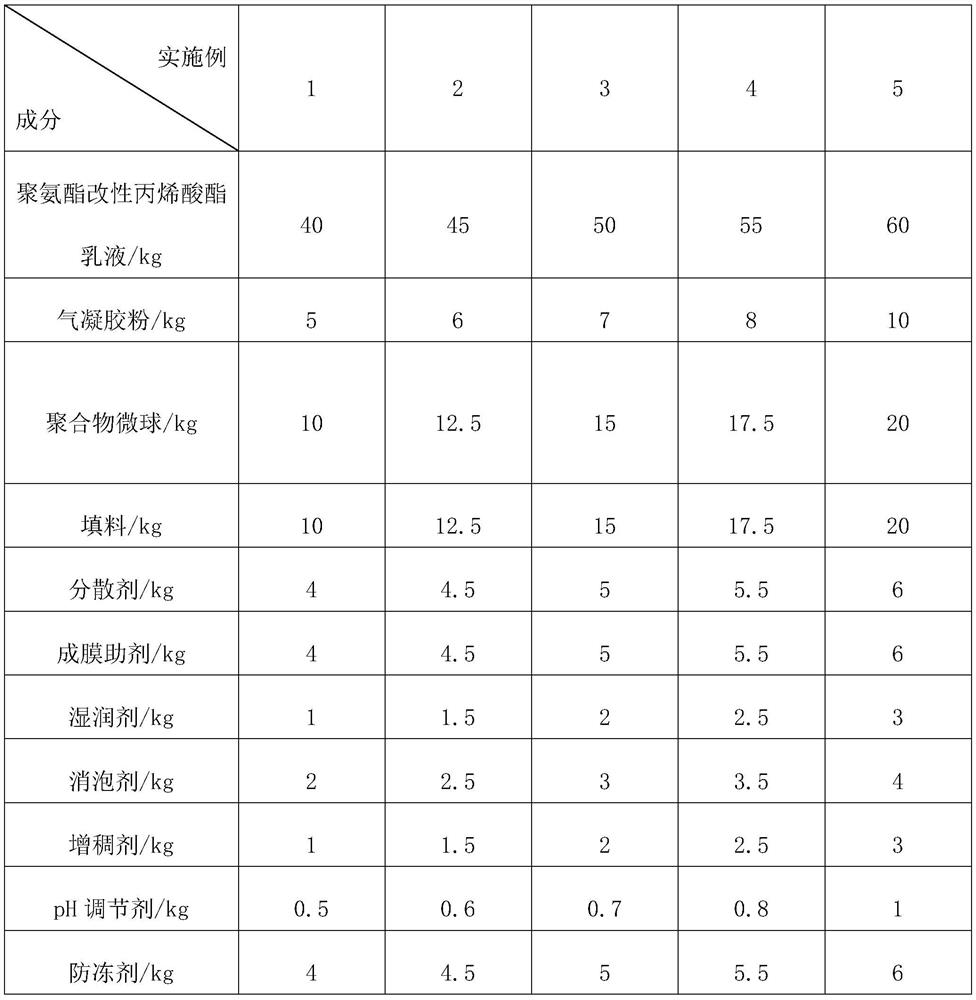

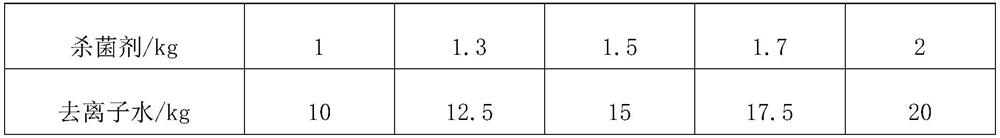

[0058] A thermal insulation coating, the raw materials used in its preparation include polyurethane modified acrylate emulsion, airgel powder, polymer microspheres, fillers, dispersants, film-forming aids, wetting agents, defoamers, thickeners, For pH adjuster, antifreeze, bactericide and deionized water, the specific usage amount of each component raw material is shown in Table 1.

[0059] Among them, the particle size of the airgel powder is 50 μm, which is collected from Keon Nano, the model is KNF-W50, the porosity is ≥ 90%, the thermal conductivity is 0.017-0.023W / (m K), and the specific surface area is 400-700m 2 / g, pore diameter ≈15nm.

[0060] The polymer microspheres are composed of porous polystyrene microspheres with a particle size of 50 μm and monodisperse polystyrene microspheres with a particle size of 0.02 μm in a weight ratio of 1:0.1.

[0061] In addition, the specific types of fillers, dispersants, film-forming aids, wetting agents, defoamers, thickeners, ...

Embodiment 2-5

[0067] A kind of thermal insulation coating, except that each raw material component and its corresponding weight are different from Example 1, other conditions are all the same, as shown in Table 1 specifically.

[0068]

[0069]

[0070] Table 1

Embodiment 6-9

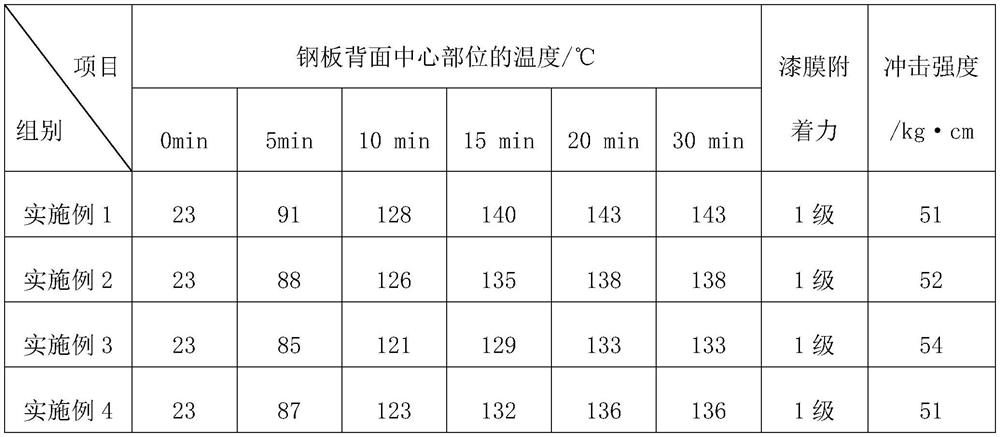

[0091] A thermal insulation coating, except that the particle diameters of porous polystyrene microspheres and monodisperse polystyrene microspheres are different from Example 3, other conditions are the same, porous polystyrene microspheres and monodisperse polystyrene microspheres The particle diameters of the balls are specifically shown in Table 3.

[0092]The coatings prepared in Examples 6-9 were taken as test samples, and the thermal insulation properties, paint film adhesion and impact strength of the coatings in the examples and comparative examples were measured, and included in Table 3 below.

[0093]

[0094]

[0095] table 3

[0096] As can be seen from the data in Table 3, after the steel plate coated with the thermal insulation coating obtained in Examples 6-9 is irradiated by the simulated light source for 20 minutes, the temperature at the center of the back of the steel plate remains substantially constant. At this time, the temperature at the center of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com