Protective clothing fabric as well as preparation method and application thereof

A technology for protective clothing and fabrics, applied in textiles and papermaking, textiles, digging fabrics, etc., can solve problems such as poor durability of anti-metal fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] According to one aspect of the present invention, a kind of preparation method of above-mentioned protective clothing fabric, described preparation method comprises the following steps:

[0059] (a), preparation of yarn A: blending phosphorus-based or silicon-nitrogen-based flame-retardant viscose with wool to obtain sheath yarn; then compounding sheath yarn with core yarn to obtain core-spun yarn; Yarn and stretch yarn, obtain yarn A;

[0060] (b), preparing yarn B: blending flame-retardant viscose and nylon staple fiber to obtain a single yarn, and then combining two single yarns to obtain yarn B;

[0061] (c) Weaving: Weaving the yarn A and the yarn B alternately in warp and weft to obtain the protective clothing fabric.

[0062] In the preparation method of the above-mentioned protective clothing fabric provided by the present invention, the preparation method first uses wool, flame-retardant viscose, nylon, and elastic yarn to prepare yarn A, and uses flame-retard...

Embodiment 1

[0074] A protective clothing fabric, the protective clothing fabric is mainly obtained by weaving yarn A and yarn B through alternate arrangement of warp and weft, wherein:

[0075] The grammage of described protective clothing fabric is 260g / m 2 , a yarn A is composed of two 150D high-strength core-spun yarns and 30D elastic yarns, and yarn B is composed of two 210D single yarns,

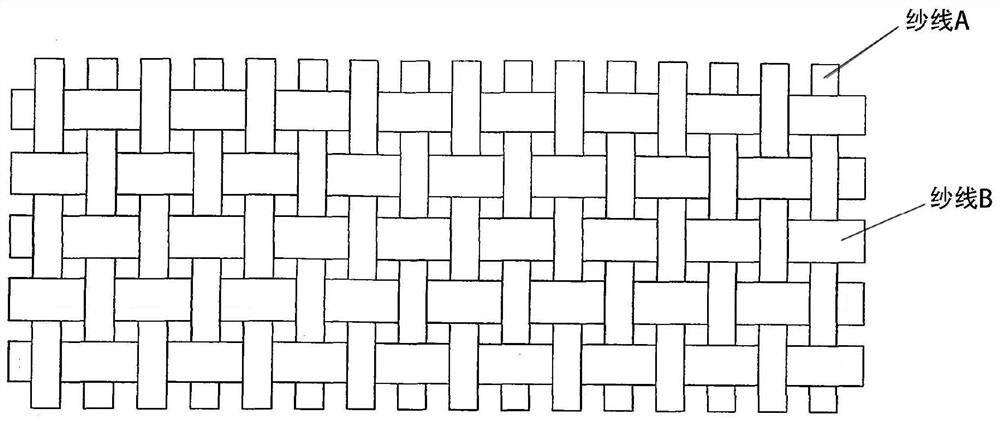

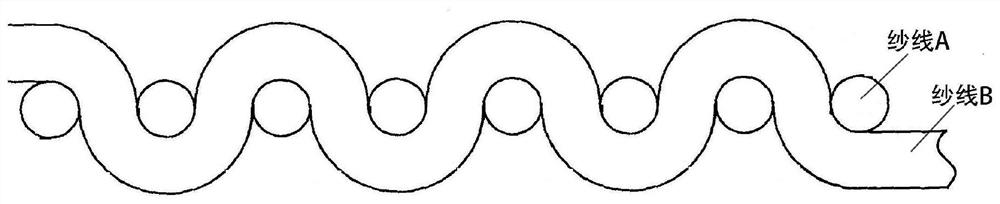

[0076] Such as figure 1 As shown, the fabric is alternately woven with two kinds of yarns of different thicknesses 1+1 to form a concave-convex fabric structure and a 2 / 1 twill weave.

[0077] The high-strength core-spun yarn is a core-spun yarn composed of a core yarn and an outer sheath yarn, and its fineness is 150D. The core yarn is made of high-strength wear-resistant filament raw material, that is, high-strength PA6 filament with a denier of 10D and a strength greater than 80cn / tex.

[0078] The outer covering sheath yarn is a mixture of short fibers, which is composed of flame-retardant s...

Embodiment 2

[0099]A protective clothing fabric, the protective clothing fabric is mainly obtained by weaving yarn A and yarn B through alternate arrangement of warp and weft, wherein:

[0100] The grammage of described protective clothing fabric is 260g / m 2 , one kind of yarn A is made of two 130D high-strength core-spun yarns and 15D elastic yarn, yarn B is made of two 210D single yarns and the fabric is alternately woven by two kinds of yarns with different thicknesses 1+1 to form concave and convex Fabric construction, 2 / 1 twill weave.

[0101] The high-strength core-spun yarn is a core-spun yarn composed of a core yarn and an outer sheath yarn, and its fineness is 130D. The core yarn is made of high-strength wear-resistant filament raw material, that is, high-strength PA6 filament with a denier of 15D and a strength greater than 80cn / tex.

[0102] The outer sheath yarn is a mixture of short fibers, which is composed of flame-retardant staple fiber raw materials, namely Lenzing flame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com