Construction method of structural combined ice column with bamboo framework

A construction method and bamboo technology, applied in the direction of columns, pillars, pier columns, etc., can solve problems such as inability to fully ensure smooth assembly, inability to fully recycle and reuse, and difficulty in transportation of the overall structure, so as to overcome the lack of gripping force and improve the use of The effect of improving the service life and compressive stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

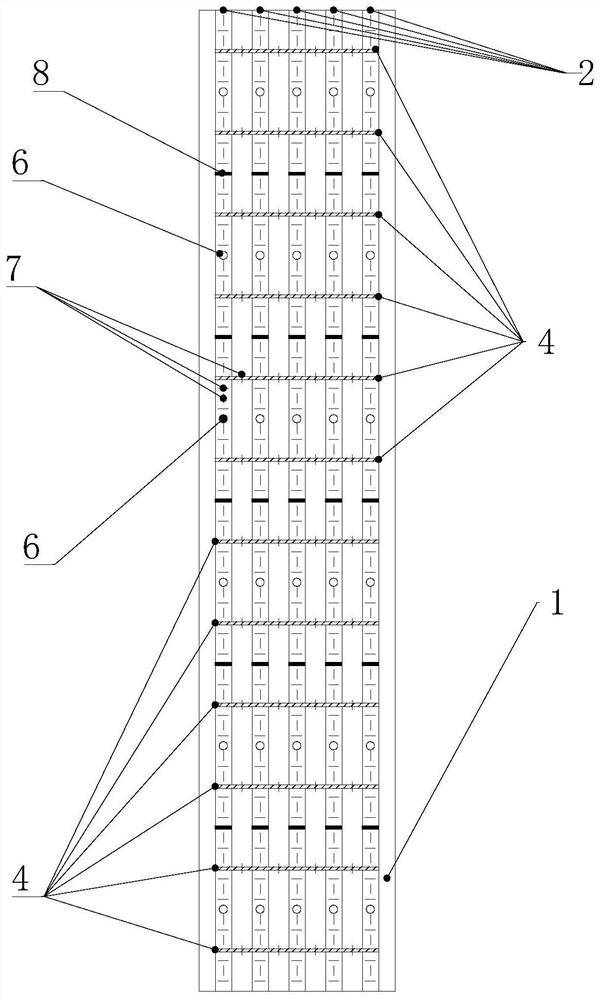

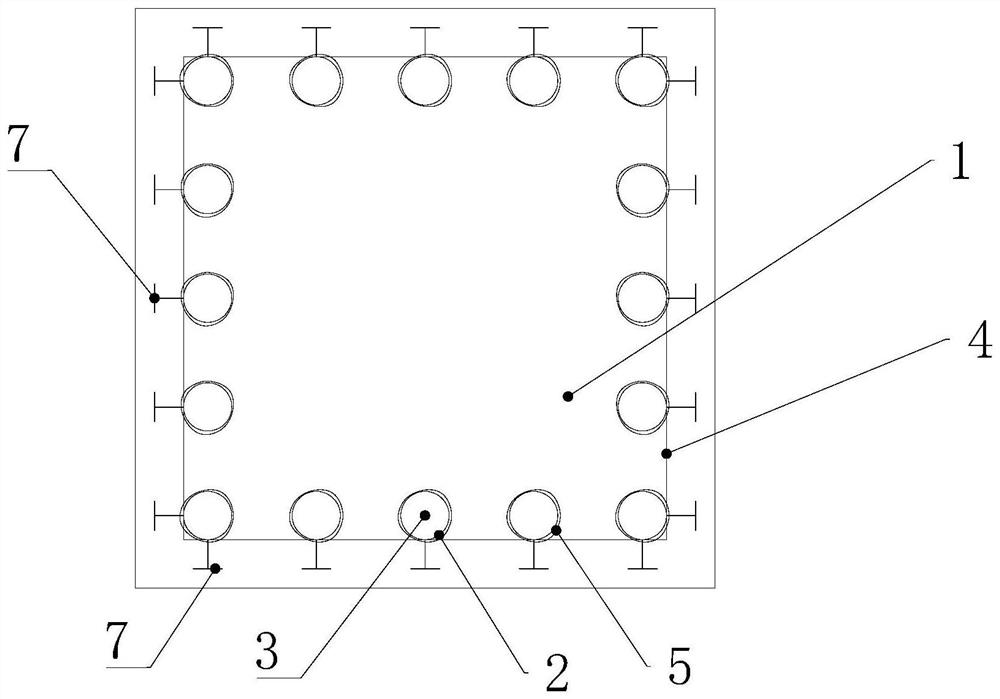

[0070] Such as Figure 7 As shown, the structure of embodiment 2 is the same as that of embodiment 1, the only difference is: the cross-sectional shape of the bamboo skeleton is consistent with the cross-sectional shape of the icicle main body, and the cross-sectional shape of the bamboo skeleton and the cross-sectional shape of the icicle main body are circular shape, the cross-sectional shape of the formed structural combination icicle is circular.

[0071] A kind of construction method of the structure combined icicle with bamboo skeleton of the present invention, comprises the following steps:

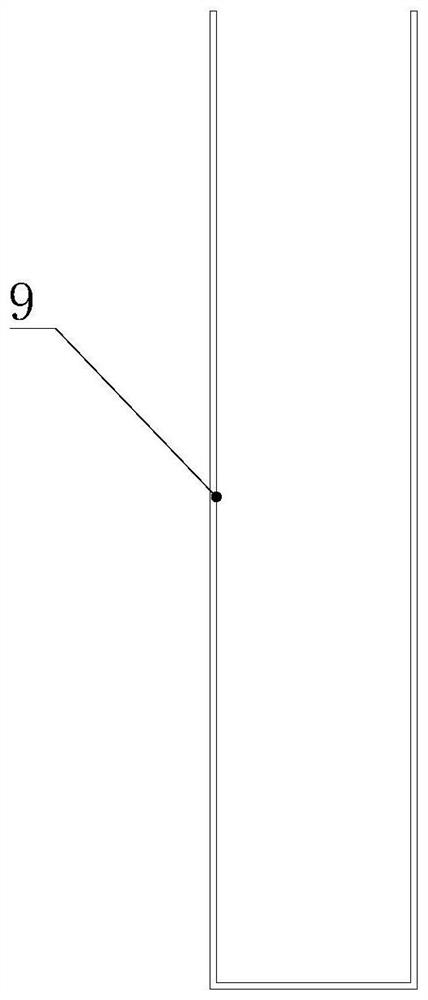

[0072] (1), design and process each plate of wooden formwork (9), disassemble after pre-assembly is correct;

[0073] (2), prefabricated hollow bamboo, long bamboo slices, wire binding and steel nails, as shown in Figure 6 (a);

[0074] (3), open pouring hole (6) at the same side of each bamboo section section of hollow bamboo, as shown in Figure 6 (b);

[0075] (4) Transport th...

Embodiment 3

[0084] Such as Figure 9 As shown, the structure of embodiment 3 is the same as that of embodiment 1, and the only difference is that the cross-sectional shape of the bamboo skeleton is consistent with the cross-sectional shape of the main body of the icicle, and the cross-sectional shape of the bamboo skeleton and the cross-sectional shape of the main body of the icicle are rectangular , then the cross-sectional shape of the formed structural combination icicle is a rectangle.

[0085] A kind of construction method of the structure combined icicle with bamboo skeleton of the present invention, comprises the following steps:

[0086] (1), design and process each plate of wooden formwork (9), disassemble after pre-assembly is correct;

[0087] (2), prefabricated hollow bamboo, long bamboo slices, wire binding and steel nails, as shown in Figure 6 (a);

[0088] (3), open pouring hole (6) at the same side of each bamboo section section of hollow bamboo, as shown in Figure 6 (b)...

Embodiment 4

[0098] Such as Figure 11 As shown, the structure of embodiment 4 is the same as that of embodiment 1, and the only difference is that the cross-sectional shape of the bamboo skeleton is consistent with the cross-sectional shape of the icicle main body, and the cross-sectional shape of the bamboo skeleton and the cross-sectional shape of the icicle main body are elliptical. shape, the cross-sectional shape of the formed structural combination icicle is oval. In the present invention, the cross-sectional shape of the elliptical structural combination icicle can be used as a side column of a non-corner column in engineering applications, because for a side column of a non-corner column, the bending moment in one direction is often larger than that in the other direction. The bending moment is small. At this time, if the cross-section is square or circular to combine the icicles, the performance of the material cannot be fully utilized, which will cause waste of materials. Theref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com