An upper-circle and lower-square structure slab joint dividing and lofting method

A technology of structural panels and panel seams, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve problems such as difficult installation, low utilization rate, and difficult processing, so as to reduce material loss and processing difficulty. , the overall shape of the square effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

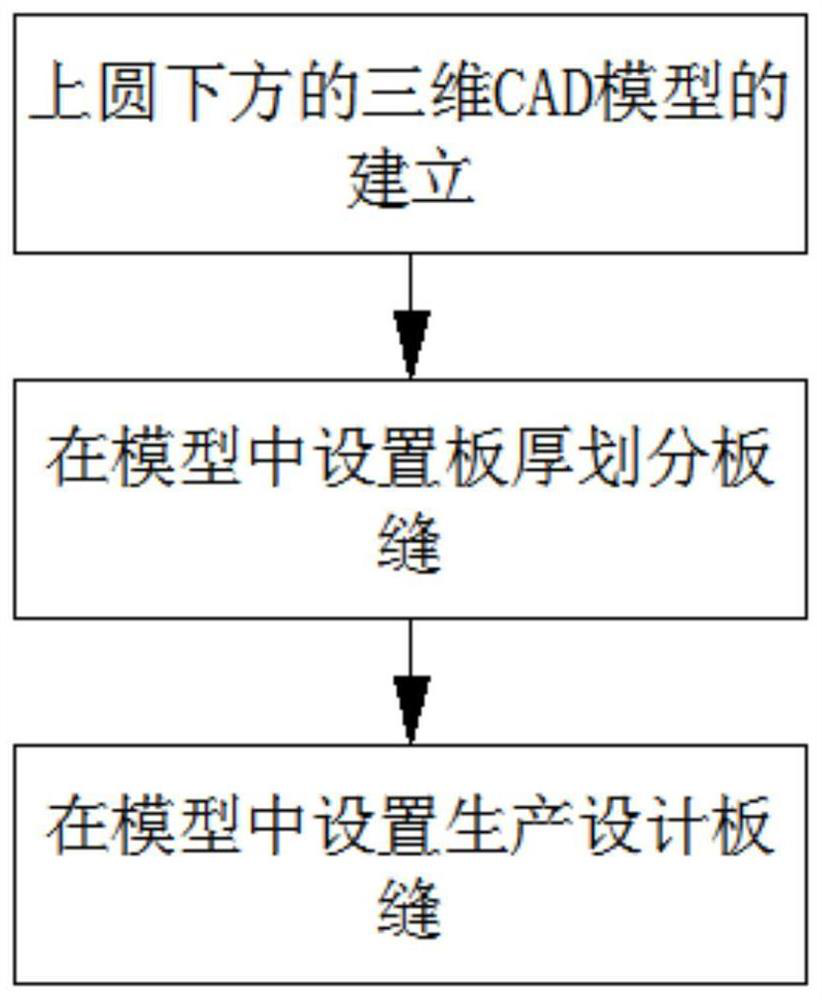

[0024] see figure 1 , 2 , the embodiment of the present invention discloses a method for dividing structural slab seams below the upper circle, including the following steps:

[0025] Step 1. Establish a model, first use CAD software to make a CAD model under the three-dimensional upper circle according to the requirements of the design drawings;

[0026] Step 2. Set the plate thickness division plate seam, divide the plate seam according to the natural plate seam required by the detailed design drawing, and divide the plate seam strictly according to the requirements of the detailed design drawing, and do not modify it when doing production design;

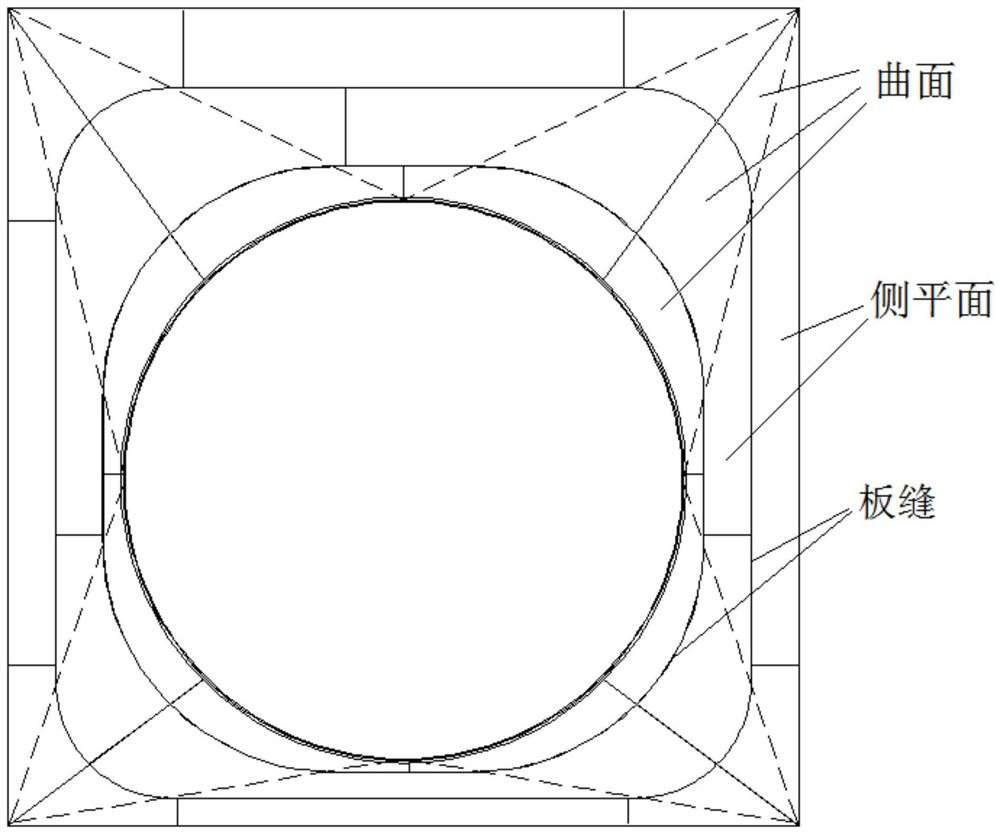

[0027] Step 3. Set the production design plate seam, set the plate seam according to the requirements of on-site construction, processing and ordering, when setting the production design plate seam, ensure that the plate seam is set in the triangular plate surrounded by the tangent point line below the upper circle, because the ...

Embodiment 2

[0031] see figure 1 , 2 , the embodiment of the present invention discloses a method for dividing structural slab seams below the upper circle, including the following steps:

[0032] Step 1. Establish a model, first use CAD software to make a CAD model under the three-dimensional upper circle according to the requirements of the design drawings;

[0033] Step 2. Set the plate thickness division plate seam, divide the plate seam according to the natural plate seam required by the detailed design drawing, and divide the plate seam strictly according to the requirements of the detailed design drawing, and do not modify it when doing production design;

[0034] Step 3. Set the production design plate seam, set the plate seam according to the requirements of on-site construction, processing and ordering, when setting the production design plate seam, ensure that the plate seam is set in the triangular plate surrounded by the tangent point line below the upper circle, because the ...

Embodiment 3

[0038] see figure 1 , 2 , the embodiment of the present invention discloses a method for dividing structural slab seams below the upper circle, including the following steps:

[0039] Step 1. Establish a model, first use CAD software to make a CAD model under the three-dimensional upper circle according to the requirements of the design drawings;

[0040] Step 2. Set the plate thickness division plate seam, divide the plate seam according to the natural plate seam required by the detailed design drawing, and divide the plate seam strictly according to the requirements of the detailed design drawing, and do not modify it when doing production design;

[0041] Step 3. Set the production design plate seam, set the plate seam according to the requirements of on-site construction, processing and ordering, when setting the production design plate seam, ensure that the plate seam is set in the triangular plate surrounded by the tangent point line below the upper circle, because the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com