Fuel cell air-cooling integrated membrane electrode structure and preparation method thereof

A membrane electrode structure, fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc. Simple, effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

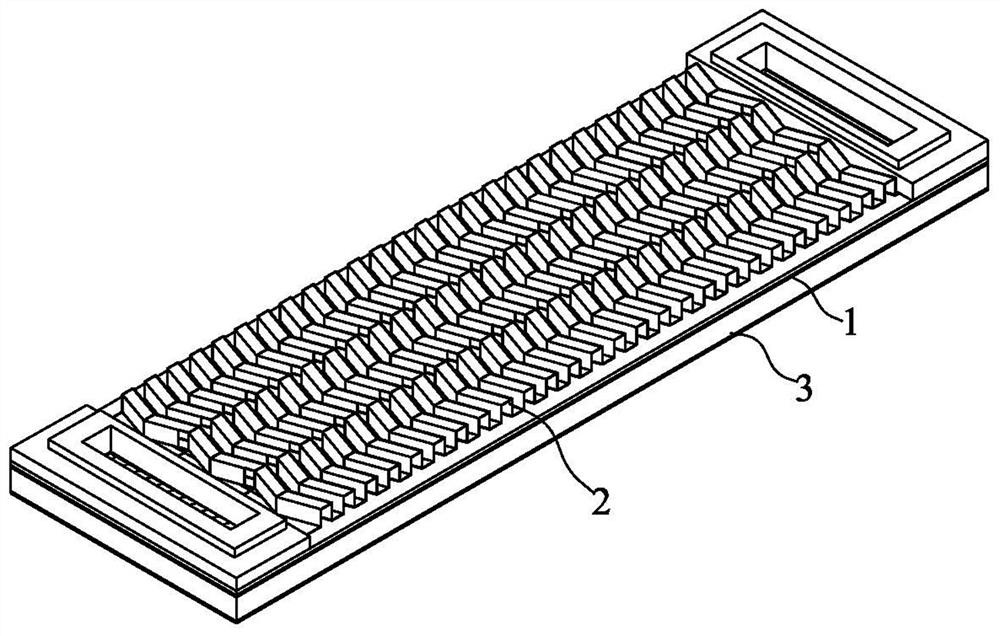

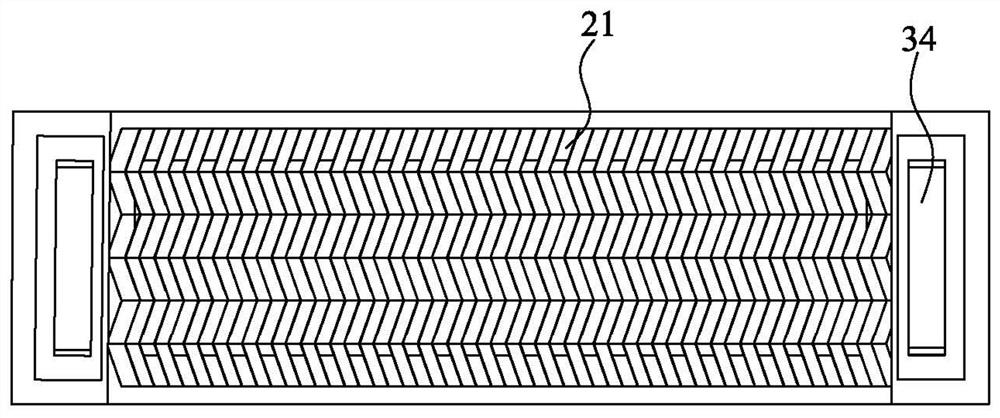

[0038] Such as Figure 1~12 As shown, an air-cooled integrated membrane electrode structure for a fuel cell includes a membrane electrode assembly 1 and an air flow channel layer 2 and a hydrogen flow channel layer 3 respectively located on both sides of the membrane electrode assembly. The air flow channel layer 2 is provided with air flow channels The hydrogen flow channel layer 3 is provided with hydrogen flow channels, wherein the hydrogen flow channels are arranged along the long axis of the membrane electrode assembly 1 , and the air flow channels are arranged along the short axis of the membrane electrode assembly 1 .

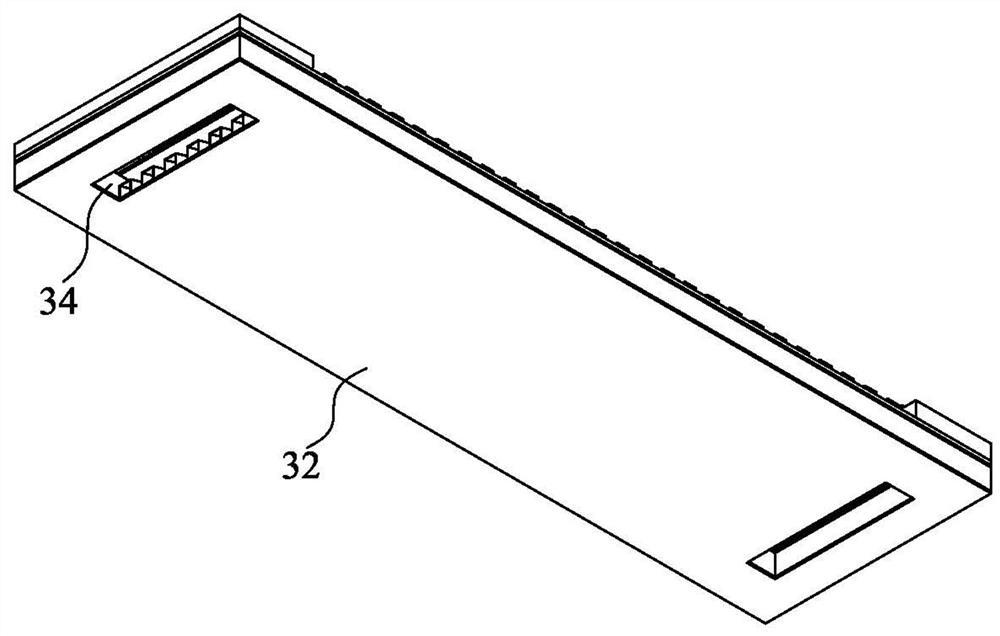

[0039] Such as Figure 5 , Figure 8~12As shown, the hydrogen flow channel layer 3 includes a hydrogen flow channel forming plate 31, the hydrogen flow channel forming plate 31 protrudes at intervals toward the membrane electrode assembly 1 to form hydrogen flow channel ridges 311, and a hydrogen flow channel ridge 311 is formed between two adjacent hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com