Textile material-based porous water splitting catalyst and preparation method therefor

A water splitting, catalyst technology, applied in the treatment of textile materials, catalyst activation/preparation, nanotechnology for materials and surface science, etc. Point and electrolyte contact area, etc., to achieve the effect of large surface area, high performance, and excellent charge transport characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

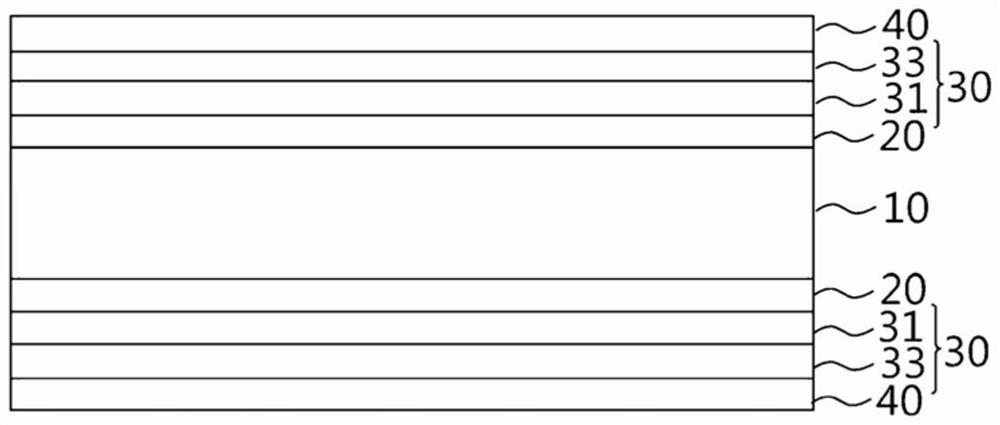

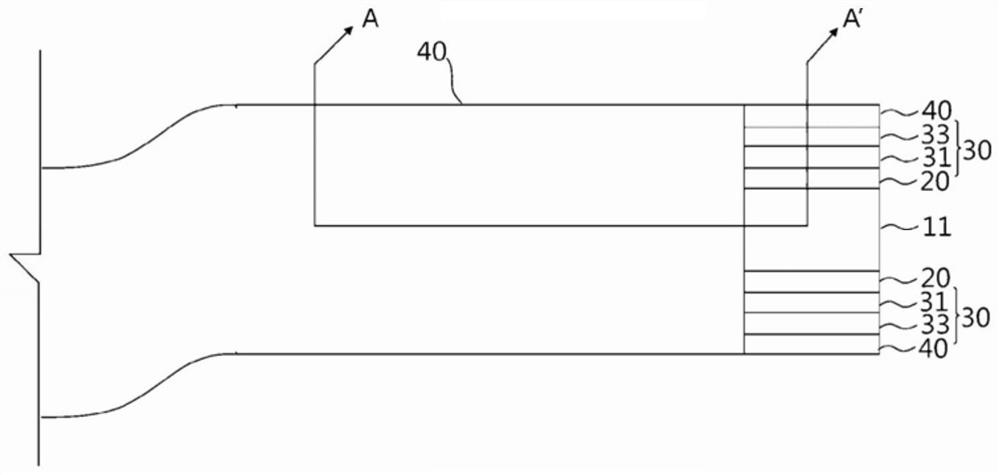

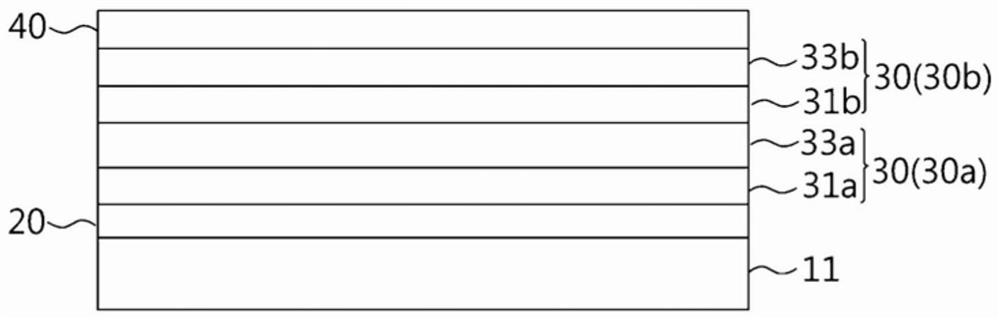

Image

Examples

Embodiment approach

[0061] A description will be given of a method for preparing a textile-based porous water-splitting catalyst according to the present invention. The fabric-based porous water-splitting catalysts are the same as those mentioned above, and their detailed descriptions are omitted or only briefly presented to avoid repetition.

[0062] Figure 7 with Figure 8 are a flowchart and a diagram, respectively, showing a method for preparing a textile-based porous water-splitting catalyst according to an embodiment of the present invention.

[0063] Such as Figure 7 with Figure 8 As shown in , the method includes: (a) preparing a first dispersion of polymeric material, and immersing a porous fabric support made by interweaving a plurality of fibers into the first dispersion to form on the surface of the fibers Forming a bonding layer (S100); (b) preparing a second dispersion of metal nanoparticles, and immersing the fabric support on which the bonding layer is formed in the second ...

Embodiment

[0072] Example: Fabrication of Fabric-Based Porous Water-Splitting Catalysts

[0073] PEI having an amine group was dispersed in ethanol to a concentration of 2 mg / mL to prepare a first dispersion. Thereafter, a porous textile support made of cellulose ("cellulose substrate") was immersed in the first dispersion for 3 hours, washed twice with ethanol, and dried with a drier. Au nanoparticles were hydrophobically stabilized with tetraoctylammonium bromide (TOABr) and dispersed in toluene to prepare a second dispersion. Then, the fabric support was immersed in the second dispersion for 1 h, washed twice with toluene, dried with a desiccator, and immersed in a 2 mg / mL solution of diethylenetriamine (DETA) in ethanol (the third dispersion body) for 30 minutes. DETA is a unimolecular compound with an amine group. Likewise, the fabric support was washed twice with ethanol and dried. Sequential impregnation in the second and third dispersions resulted in the formation of a (TOABr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com