High-viscosity perovskite quantum dot conductive ink and preparation method thereof

A technology of conductive ink and quantum dots, applied in the field of material engineering, can solve the problems of poor phase stability of all-inorganic quantum dots, affecting the electronic coupling of quantum dots, unfavorable application of optoelectronic devices, etc., and achieves good charge transport properties, simple process and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Synthesis of FAPbI by Thermal Injection Method According to the Prior Art 3 Quantum dots were prepared into a 70 mg / mL n-octane solution, sealed and placed in an air environment with a temperature of 25 °C and a relative humidity of 30%, and left to stand for 7 days to obtain FAPbI 3 Quantum dot conductive ink.

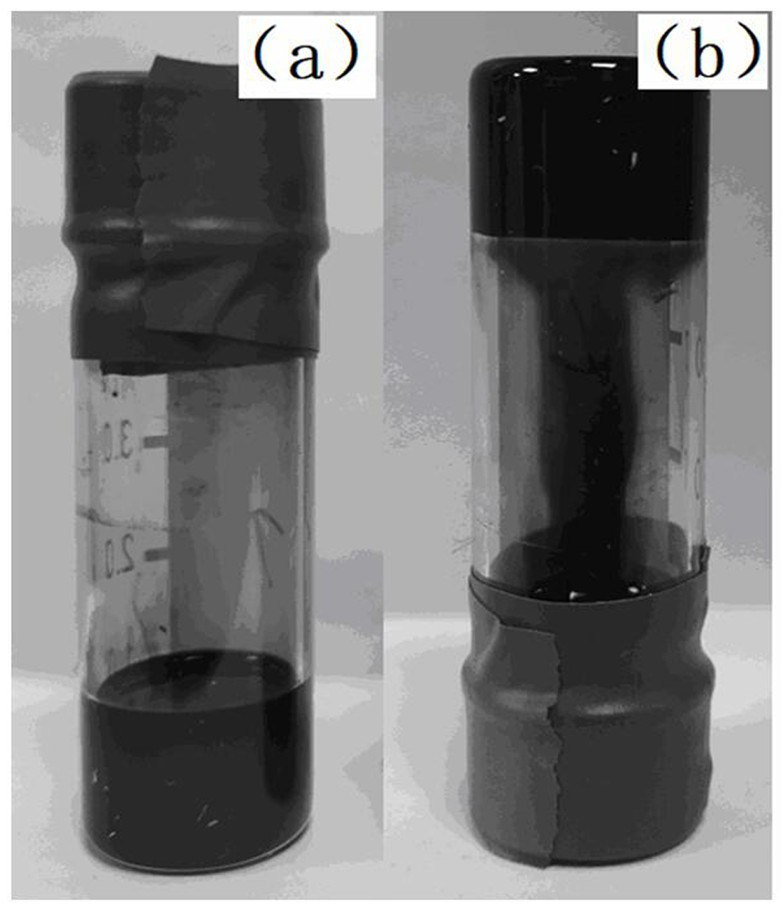

[0026] See attached figure 1 , which is the FAPbI provided by this example 3 Physical photo of quantum dot conductive ink, (a) The picture shows the upright FAPbI 3 Quantum dot conductive ink, (b) The picture shows the inverted FAPbI 3 Quantum dot conductive ink, the picture shows that the prepared conductive ink has high viscosity.

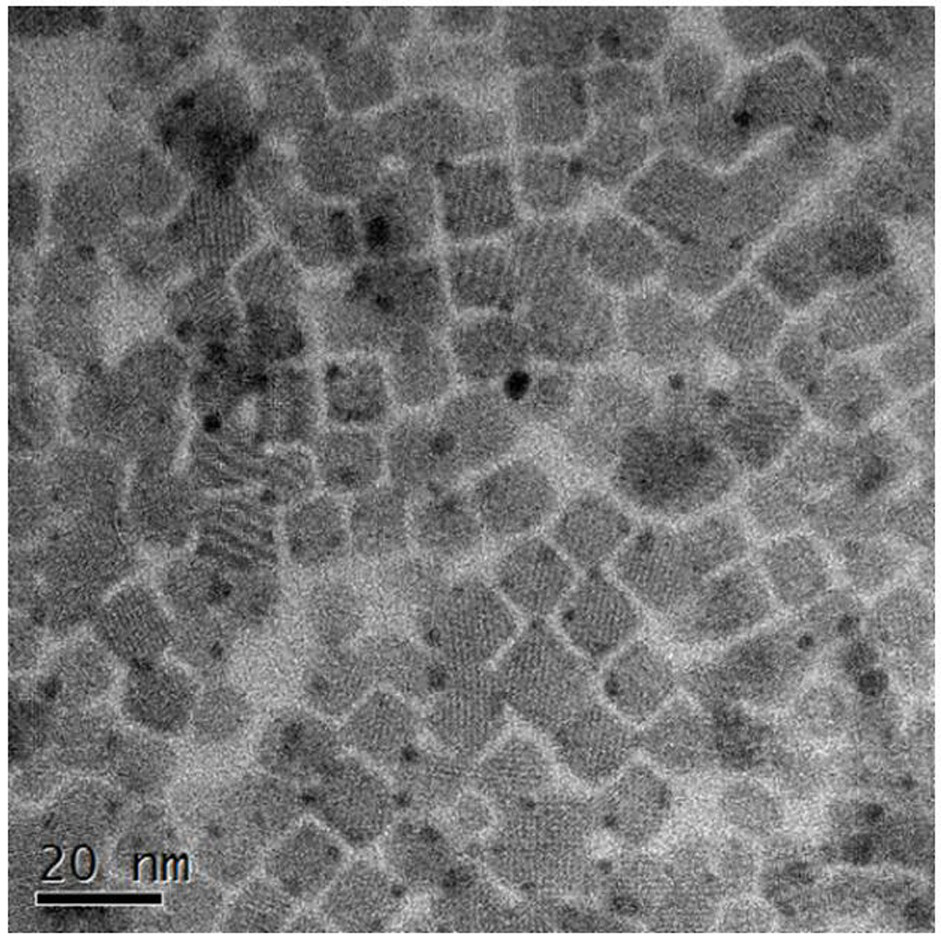

[0027] See attached figure 2 , which is the FAPbI provided by this example 3 TEM image of quantum dot conductive ink;

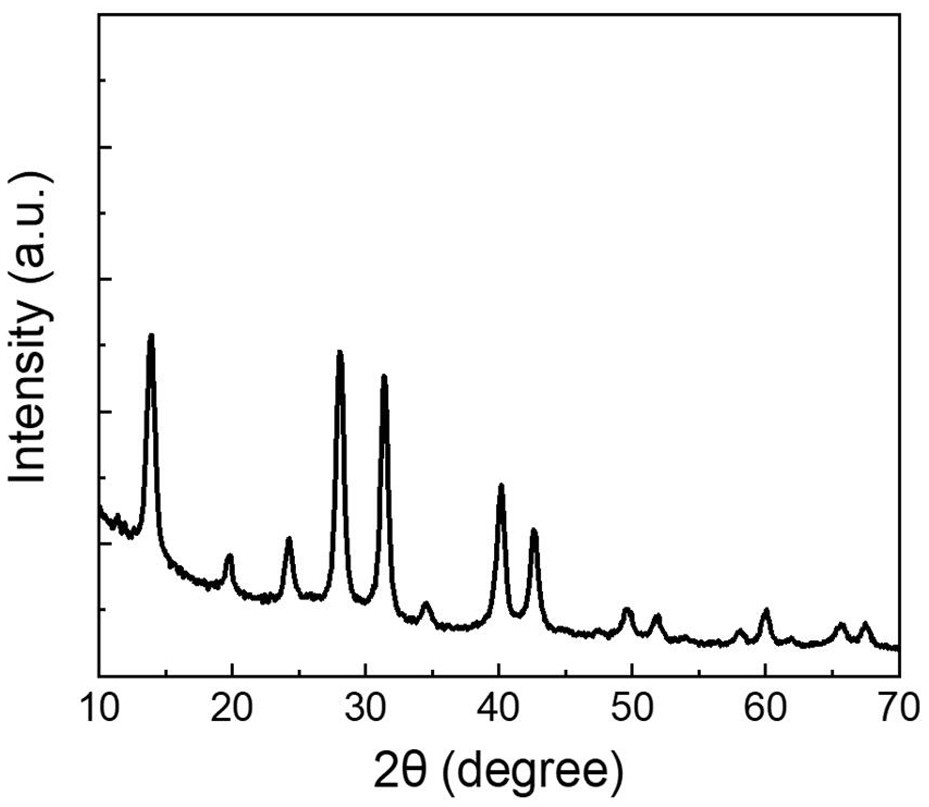

[0028] See attached image 3 , which is the FAPbI provided by this example 3 XRD pattern of quantum dot conductive ink;

[0029] See attached Figure 4 , which is the fluorescence emission spectrum fi...

Embodiment 2

[0031] FAPbI was synthesized separately by hot injection method 3 and CsPbI 3 Quantum dots were prepared into 70 mg / mL n-hexane solution; FAPbI was mixed at a volume ratio of 1:3 3 and CsPbI 3 The quantum dot solution was fully mixed for about 30 minutes, and the A-site cation exchange was carried out to prepare alloy quantum dots; sealed and placed in a dry box at 40 °C, and left to stand for 5 days, the prepared (FACs)PbI 3 Quantum dot conductive ink.

[0032] See attached Figure 5 , is the fluorescence emission spectrum diagram of the conductive ink prepared in this embodiment.

Embodiment 3

[0034] Synthesis of FAPbI by thermal injection 3 and CsPbBr 3 Quantum dots were prepared into 70 mg / mL and 50 mg / mL chloroform solutions respectively, and the two were fully mixed at a ratio of 1:3 for about 30 minutes, and the A and X positions were exchanged for cations and anions to prepare alloy quantum dots; sealed and placed In the air environment of 20 ℃, after standing for 240 hours, the prepared (FACs)Pb(IBr) 3 Quantum dot conductive ink.

[0035] See attached Figure 6 , is the fluorescence emission spectrum diagram of the conductive ink prepared in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com