Silicon-based perovskite double-diode double-sided solar cell and preparation method thereof

A double-sided solar cell and double-diode technology, applied in the field of solar cells, can solve the problems of low utilization rate of light on the light-receiving surface, immature and unstable technology, difficult to realize industrialization, etc. Effects of photoelectric conversion efficiency, excellent charge transport properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The specific implementation of this embodiment will be described below in conjunction with the accompanying drawings.

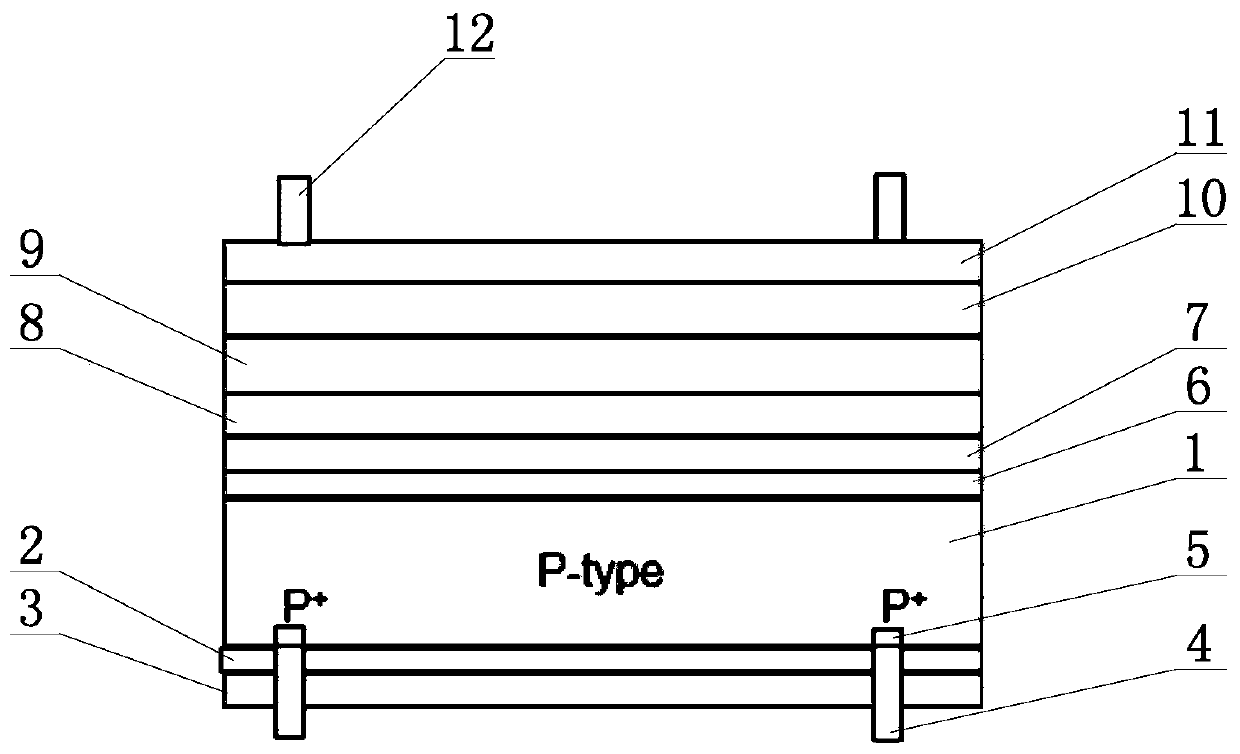

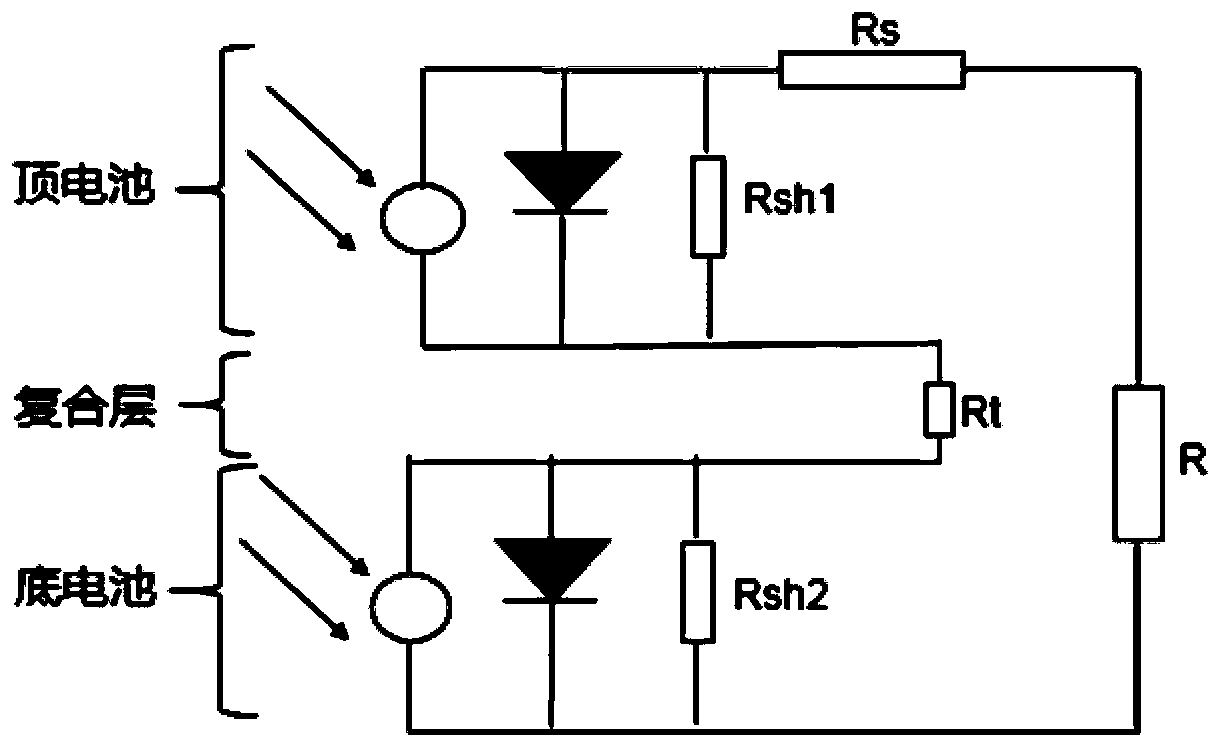

[0039] Such as figure 1 , figure 2 As shown, the silicon-based perovskite double-diode double-sided solar cell of the present embodiment includes a bottom cell, a composite layer 7 and a top cell, and the bottom cell includes a P-type silicon substrate 1, an AlOx thin film layer 2, a SiONx thin film layer 3 and a bottom cell. Electrode 4, AlOx thin film layer 2, and SiONx thin film layer 3 are sequentially prepared on the lower side of P-type silicon substrate 1, and lower electrode 4 passes through AlOx thin film layer 2 and SiONx thin film layer 3 and is connected to P+ re-doped region 5 of P-type silicon substrate 1 , N+ doped layer 6 is prepared on the front side of P-type silicon substrate 1 to form a bottom electric PN junction, and the composite layer is prepared on N+ doped layer 6, and composite layer 7 includes indium tin oxide (ITO), fluor...

Embodiment 2

[0056] The preparation method of the silicon-based perovskite double-diode double-sided solar cell of the present embodiment comprises the following steps:

[0057] 1) Surface cleaning and texture: Use a low-concentration alkaline solution to perform anisotropic corrosion on the P-type silicon substrate 1, and corrode the surface of the P-type silicon substrate 1 to form a pyramid-shaped surface morphology. Reactive alkaline solution: 1.0-1.5wt %NaOH, reaction time: 200-400s, temperature: 70-90℃, reflectivity: 11-12%;

[0058] 2) Diffusion of phosphorus at high temperature: through N 2 Diffusion source POCl 3 The steam is brought into the high-temperature diffusion furnace, and a sufficient amount of O is introduced at the same time 2 After a series of chemical reactions, phosphorus atoms diffuse into the P-type silicon chip to form an N+ doped layer 6, and the N+ doped layer 6 cooperates with the P-type silicon substrate 1 to form a bottom cell PN junction, N 2 Flow: 500-8...

Embodiment 3

[0072] The preparation method of the silicon-based perovskite double-diode double-sided solar cell of the present embodiment comprises the following steps:

[0073] 1) Surface cleaning and texture: Use a low-concentration alkaline solution to perform anisotropic corrosion on the P-type silicon substrate 1, and corrode the surface of the P-type silicon substrate 1 to form a pyramid-shaped surface morphology. Reactive alkaline solution: 1.0-1.5wt %NaOH, reaction time: 200-400s, temperature: 70-90℃, reflectivity: 11-12%;

[0074] 2) Diffusion of phosphorus at high temperature: through N 2 Diffusion source POCl 3 The steam is brought into the high-temperature diffusion furnace, and a sufficient amount of O is introduced at the same time 2 After a series of chemical reactions, phosphorus atoms diffuse into the P-type silicon chip to form an N+ doped layer 6, and the N+ doped layer 6 cooperates with the P-type silicon substrate 1 to form a bottom cell PN junction, N 2 Flow: 500-8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com