Treatment device and method for aluminum alloy machining wastewater

A technology for mechanical processing and wastewater treatment, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as low efficiency, and achieve the effect of increasing efficiency and increasing the degree of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

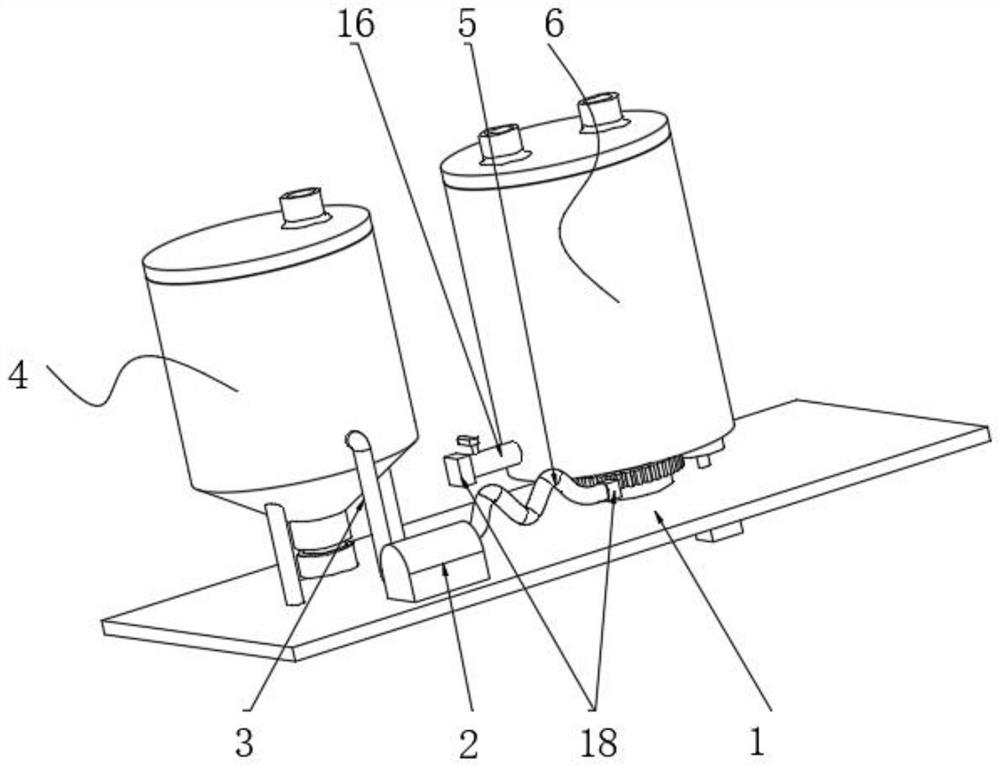

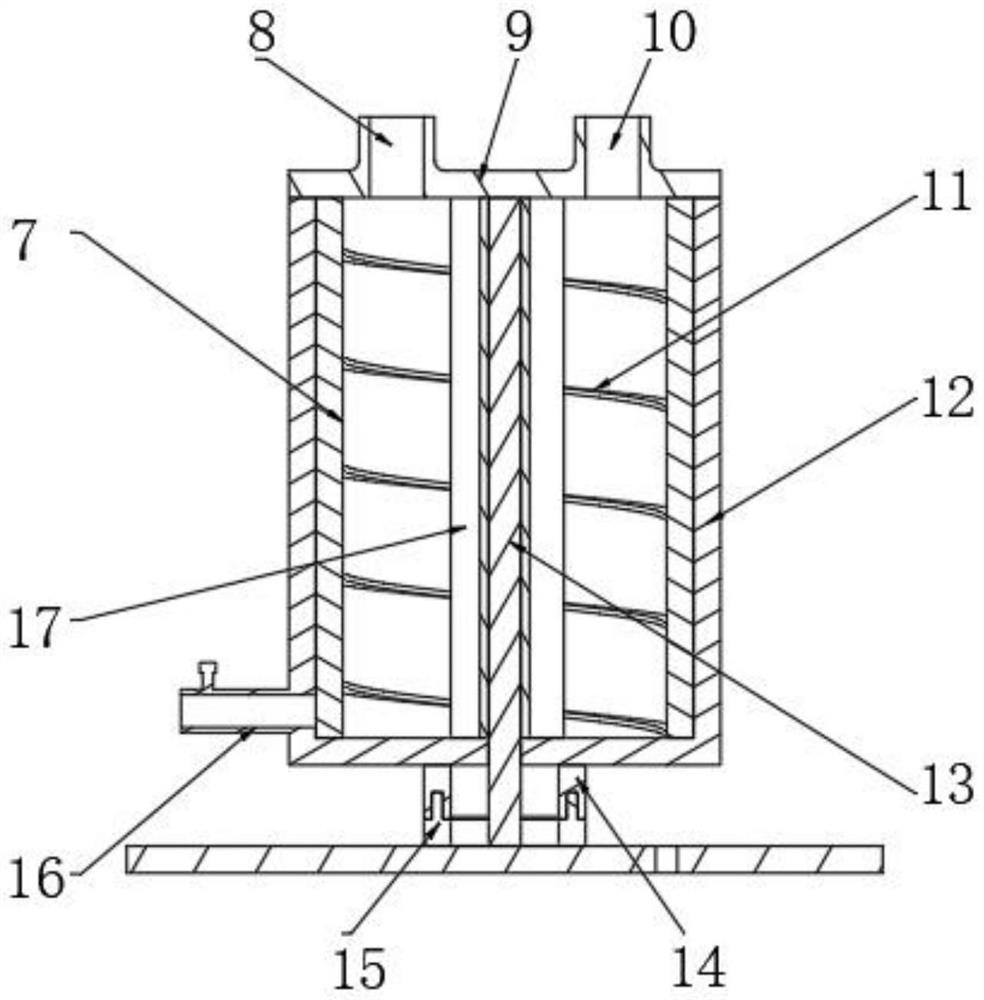

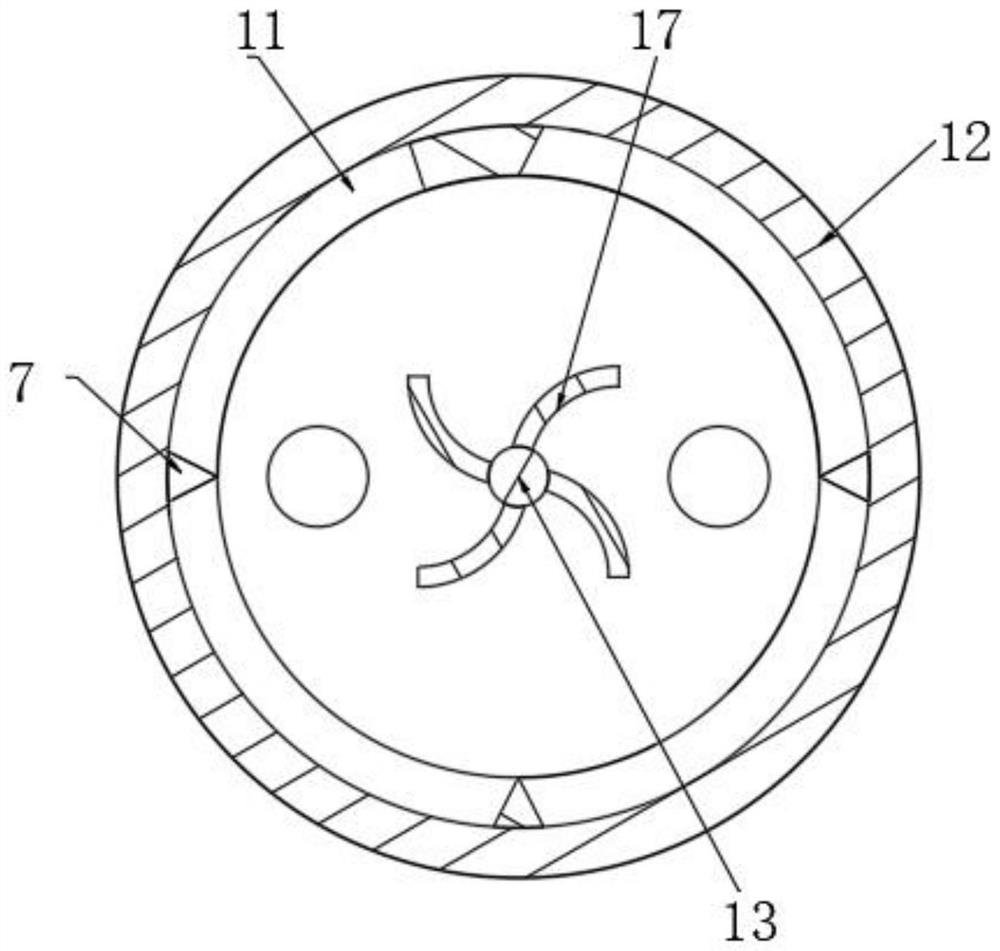

[0042] A kind of aluminum alloy machining wastewater treatment device and method thereof, such as figure 1 , 2 As shown, comprise base 1, the top outer wall of described base 1 is respectively provided with filtering mechanism 4 and reaction mechanism 6, and described reaction mechanism 6 comprises top cover-9 and reaction tank 12 that are mutually fixed by bolts, and described reaction tank 12 The outer wall of the bottom of the bottom is fixed with a rotating cylinder 14 by bolts, and the bottom of the rotating cylinder 14 is slidably connected with a rotating cylinder 2 15, and the rotating cylinder 15 is fixed on the top outer wall of the base 1 by bolts, and the inner walls of the reaction tank 12 are respectively welded There are spiral blades 11 and four baffle plates 7 in a ninety-degree circular array. The inner wall of the reaction tank 12 is rotatably connected to a main shaft 13, and the bottom of the main shaft 13 is fixed on the top outer wall of the base 1 by bolt...

Embodiment 2

[0050] A kind of aluminum alloy machining wastewater treatment device, such as figure 1 , 5 , 6, in order to solve the filtering problem; the present embodiment makes the following improvements on the basis of embodiment 1: the filter mechanism 4 includes a filter tank 24 and a top cover 25 fixed to each other by bolts, the filter tank 24 The bottom outer wall is welded with supporting legs 28, the top outer wall of the top cover 25 is welded with a water outlet cleaning integrated pipe 26, and the inner wall of the filter tank 24 is fixed with at least three filter screens 29 in sequence along the vertical direction, and the three filter screens 29 are The filter screen 29 is along the water flow direction, and the particle size of the dirt that can be filtered decreases successively. The bottom of the filter tank 24 is conical, and the bottom outer wall of the filter tank 24 is threadedly connected with a plug 27 .

[0051] In order to solve the fast connection problem, suc...

Embodiment 3

[0054] A method for using an aluminum alloy machining wastewater treatment device, such as Figure 1-7 As shown, the specific steps are as follows:

[0055] S1: Loosen the limiting internal thread ring 35, put the filter mechanism 4 and the reaction mechanism 6 in a disconnected state, and close the water valve on the outlet pipe 16;

[0056] S2: Put the waste water and the chemical precipitation reagent into the waste water inlet pipe 8 and the reagent delivery pipe 10 respectively;

[0057] S3: Start the motor 22 to fully mix the waste water and the chemical reagent;

[0058] S4: After fully reacting, align the sealing ring 31 with the external thread protrusion 33, and tighten the limiting internal thread ring 35, and at the same time open the water valve on the liquid outlet pipe 16, start the water pump 2; filter the waste water after the reaction ;

[0059] S6: After the filtration is finished, pour clean water into the outlet water cleaning integrated pipe 26, unscre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com