Hydrophobic modified bio-based coated controlled-release fertilizer and preparation method thereof

A technology of controlled-release fertilizers and hydrophobic modifiers, applied in layered/coated fertilizers, fertilizer mixtures, solid/semi-solid fertilizers, etc. To solve the problems of easy hydrophilicity of the material, to achieve the degradability of the residual film, reduce the water penetration rate, and improve the hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1, mixing 20g bagasse liquefied polyol and 40g isophorone diisocyanate evenly to obtain coating solution A;

[0042] Step 2: Mix 10 g of coating solution A prepared in step 1 with 1 g of γ-aminopropyltriethoxysilane, stir evenly at room temperature, and react for 1 hour to obtain coating solution B;

[0043] Step 3: Preheat 1 kg of urea granules at 50°C for 10 minutes, spray 30 g of coating solution B (accounting for 3% of the mass of urea granules) onto the surface of urea granules, coat at 50°C for 20 minutes, and cure at 70°C 8min to obtain coated controlled-release fertilizer.

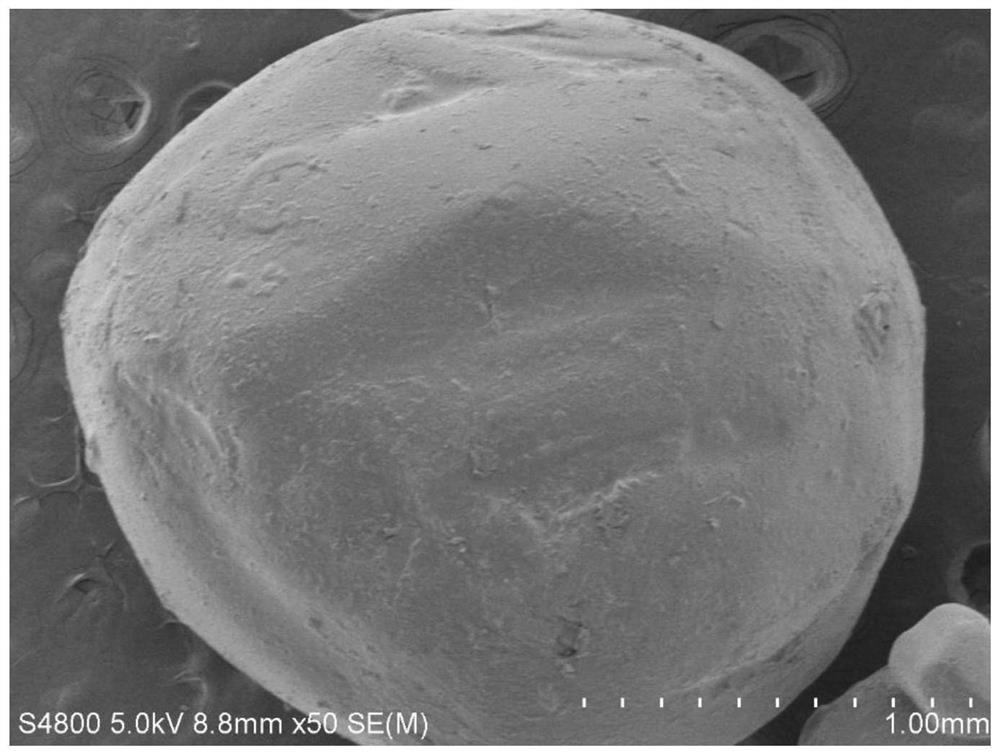

[0044] The coated controlled-release fertilizer was characterized by SEM, and its SEM picture is shown in figure 1 , it can be seen from the figure that after the coating material is hydrophobically modified, the surface of the prepared coated controlled-release fertilizer is smooth and dense, and the surface has no pores.

[0045] The coating material obtained from coating solution B...

Embodiment 2

[0048] Step 1, mix 20g bagasse liquefied polyol and 40g PM-200 evenly to obtain coating solution A;

[0049]Step 2: Mix 10 g of the coating solution A prepared in step 1 with 2 g of 3-aminopropyltrimethoxysilane, stir evenly at room temperature, and react for 1 hour to obtain the coating solution B;

[0050] Step 3: preheat 1 kg of urea granules at 70°C for 8 minutes, take 50 g of coating solution B (accounting for 5% of the mass of urea granules) and spray on the surface of urea granules, coat at 75°C for 10 minutes, and cure at 60°C 10min to obtain coated controlled-release fertilizer.

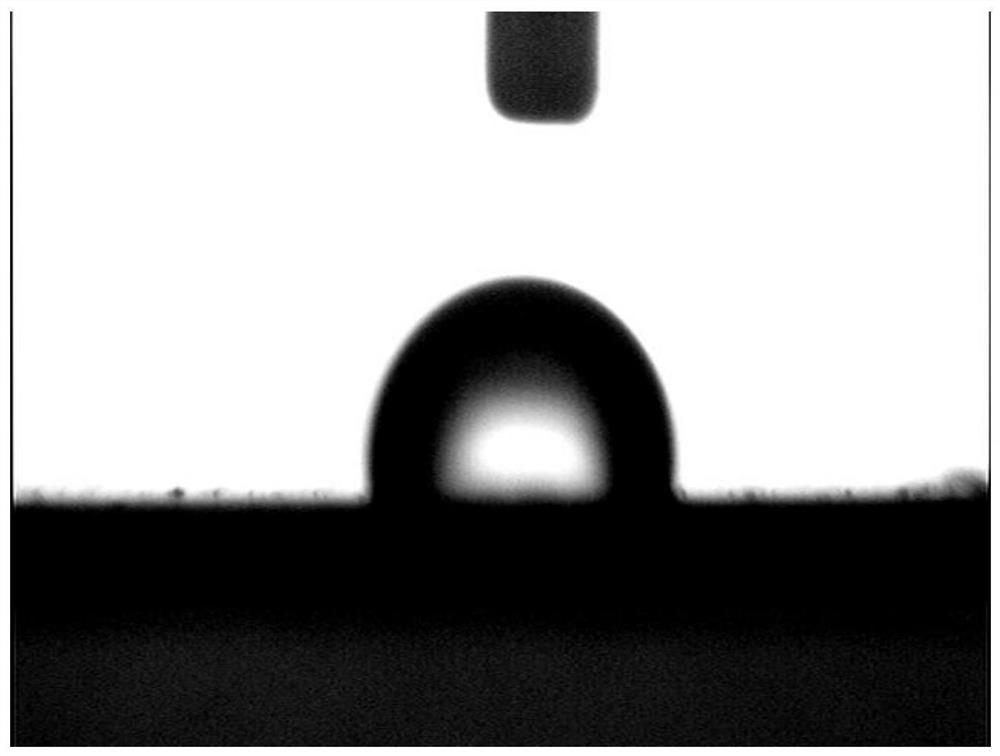

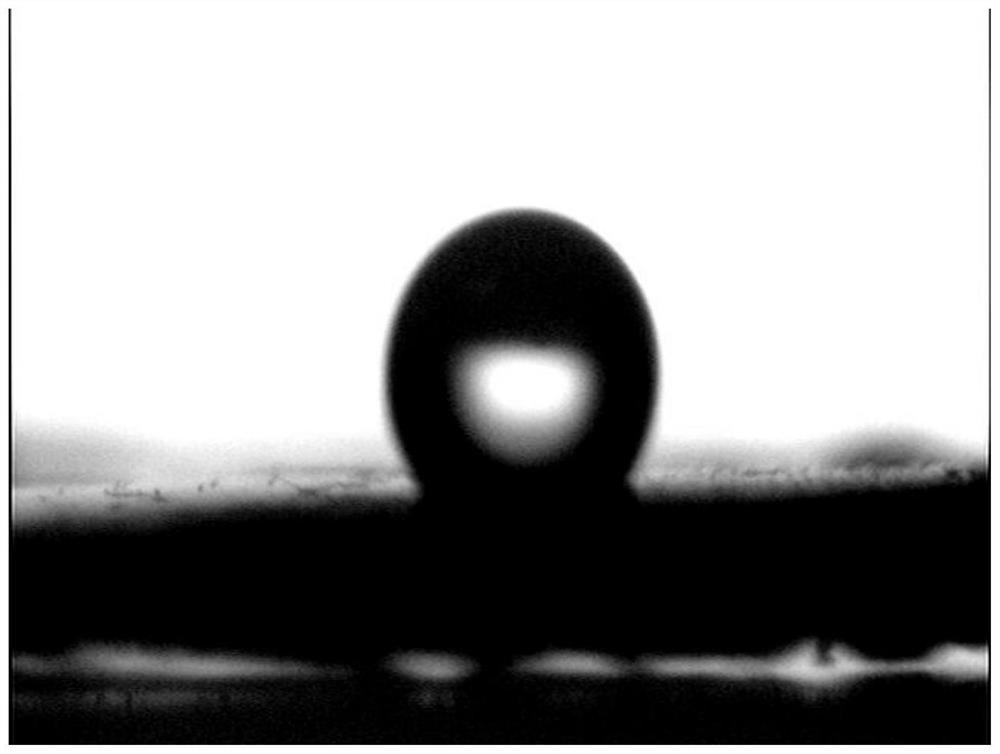

[0051] The coating material obtained from coating solution B was tested for hydrophobicity, and the contact angle is shown in image 3 , when water contacts the hydrophobically modified membrane material, the membrane material can increase the contact angle between water and the membrane layer, the contact angle is 136.76°, showing excellent hydrophobic effect.

Embodiment 3

[0053] Step 1, mixing 20g bagasse liquefied polyol and 30g diphenylmethane diisocyanate evenly to obtain coating solution A;

[0054] Step 2: Mix 10 g of the coating solution A prepared in step 1 with 1.5 g of 3-(2,3-glycidoxy)propyltrimethoxysilane, stir evenly at room temperature, and react for 1 hour to obtain the coating solution B;

[0055] Step 3: Preheat 1 kg of urea granules at 60°C for 9 minutes, spray 80 g of coating solution B (accounting for 8% of the mass of urea granules) onto the surface of urea granules, coat at 60°C for 15 minutes, and cure at 65°C 5min to obtain coated controlled-release fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com