Method for purifying bacterial cellulose membrane and application thereof

A bacterial cellulose membrane and pure water technology, which is applied in the field of bacterial cellulose membrane purification, can solve the problem of bacterial cellulose total bacterial count, appearance permeability, cytotoxicity not meeting the requirements, bacterial cellulose membrane damage, yellowing and discoloration, etc. problem, achieve the effect of avoiding discoloration, avoiding oxidation, and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

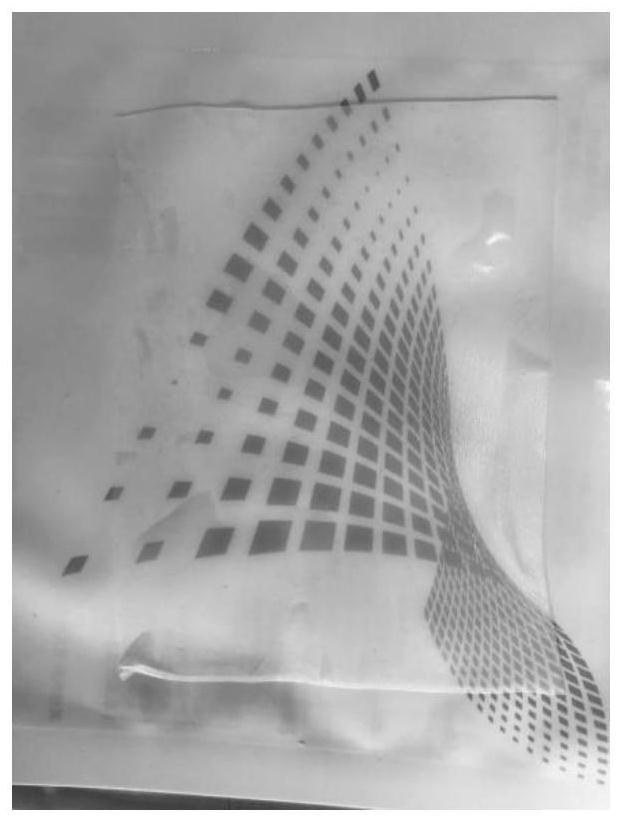

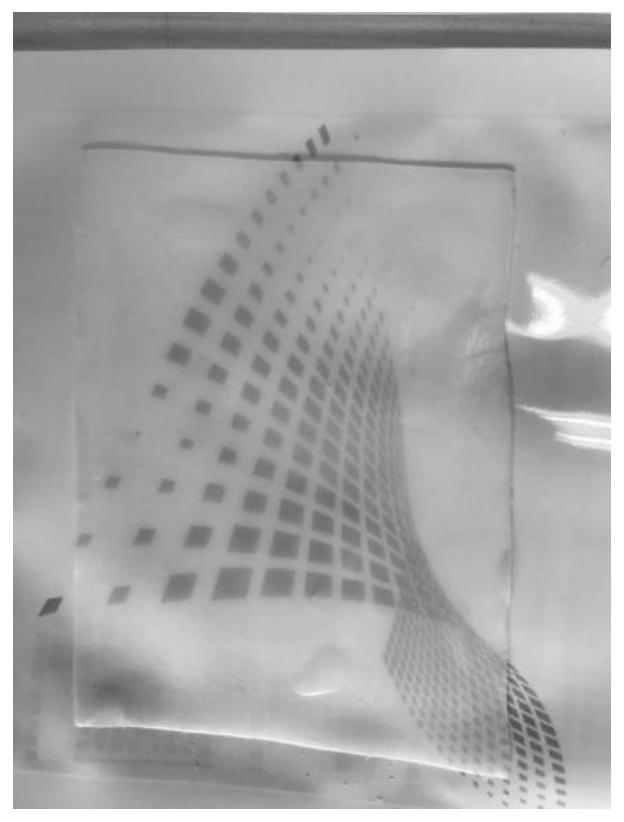

Image

Examples

Embodiment 1

[0042] (1) The fermented membrane is washed with pure water in the purification tank, and the air volume of the purification tank is set at 8m 3 / min, rinse for 45min.

[0043](2) Add hot NaOH solution to the film after the above treatment, the temperature is 65°C, the concentration is 5‰, soak for 20min, and then send it into the blast for 5h, and the blast volume is 10m 3 / min.

[0044] (3) Replace with new NaOH solution at room temperature, temperature 25°C, concentration 2‰, soak for 40 minutes, then pour 1.5‰ hydrogen peroxide into the room temperature lye soaked with diaphragm, seal and soak for 2 hours.

[0045] (4) The membrane treated in the above steps was continued to be washed with pure water for 6 times, and the pH value inside and outside the membrane reached 6.9.

[0046] (5) Put the treated membrane into steam for 30 minutes.

[0047] Mouse fibroblasts were inoculated in a 96-well plate and cultured for 24 hours until the cells grew to confluence. Using MEM ...

Embodiment 2

[0050] (1) The fermented membrane is washed with pure water in the purification tank, and the air volume of the purification tank is set at 8m 3 / min, rinse for 45min.

[0051] (2) Add hot NaOH solution to the film after the above treatment, the temperature is 60°C, the concentration is 4‰, soak for 20min, and then send it into the blast for 5h, and the blast volume is 10m 3 / min.

[0052] (3) Replace with new NaOH solution at room temperature, temperature 10°C, concentration 1‰, soak for 60 minutes, then pour 1.5‰ hydrogen peroxide into the room temperature lye soaked with diaphragm, seal and soak for 2 hours.

[0053] (4) The membrane treated in the above steps was continued to be washed with pure water for 6 times, and the pH value inside and outside the membrane reached 6.9.

[0054] (5) Put the treated membrane into steam for 30 minutes.

[0055] The experiment found that the prepared bacterial cellulose membrane was transparent and colorless.

Embodiment 3

[0057] (1) The fermented membrane is washed with pure water in the purification tank, and the air volume of the purification tank is set at 8m 3 / min, rinse for 45min.

[0058] (2) Add hot NaOH solution to the film after the above treatment, the temperature is 70 ° C, the concentration is 10‰, soak for 20 minutes, and then send it into the blast for 5 hours, and the blast volume is 10m 3 / min.

[0059] (3) Replace with new NaOH solution at room temperature, temperature 30°C, concentration 3‰, soak for 30 minutes, then pour 1.5‰ hydrogen peroxide into the room temperature lye soaked with diaphragm, seal and soak for 2 hours.

[0060] (4) The membrane treated in the above steps was continued to be washed with pure water for 6 times, and the pH value inside and outside the membrane reached 6.9.

[0061] (5) Put the treated membrane into steam for 30 minutes.

[0062] The experiment found that the prepared bacterial cellulose film was flat, without air bubbles and colorless.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com