Cyclocarya paliurus seed treatment method

A technology of seed treatment and Cyclocarya paliurus, which is applied in the field of plant cultivation, can solve the problems of Cyclocarya paliurus seed damage, low seed germination rate, and complicated operation, so as to reduce time cost and economic cost, increase germination rate, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

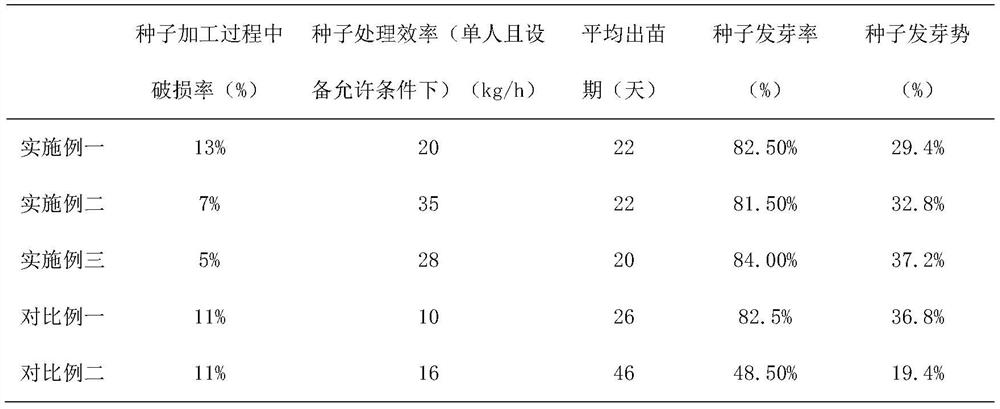

Embodiment 1

[0024] In the present embodiment, the Cyclocarya paliurus seed treatment method uses the Cyclocarya paliurus seeds plucked from the Cyclocarya paliurus seeds planted in the Huaihua Chinese area at the end of September as raw materials. Skin grinding, during skin grinding, Cyclocarya paliurus seeds are directly added to the mixing equipment (concrete mixer) with built-in inner wall blades, and the skin grinding is carried out at a speed of 30 rpm, until the amount of grinding to the skin is 1 / 2 of the thickness of the skin. 1 / 2 to 2 / 3 hours, at this time, the waxy matter on the surface of Cyclocarya paliurus seeds and the epidermis of the hard shell are worn away. During this process, the loss rate of Cyclocarya paliurus seeds is generally 12-20%. In this example it is 13%.

[0025] Sodium hypochlorite solution with a mass concentration of 21% is used as the seed coat softening agent to soften and soak the seeds that have been ground and removed the hard shell layer. The soakin...

Embodiment 2

[0029] In the present embodiment, the Cyclocarya paliurus seed treatment method uses the Cyclocarya paliurus seeds plucked from the Cyclocarya paliurus seeds planted in the Huaihua Chinese area at the end of September as raw materials. Microdermabrasion, add Cyclocarya paliurus seeds directly into the horizontal drum, and add small rubber abrasive balls and large rubber abrasive balls with a ratio of 3:1. The diameter of the small rubber abrasive balls is 2-3cm. The diameter of the large rubber grinding ball is 3 to 4 cm. The mass ratio of the grinding ball and Cyclocarya paliurus seeds is controlled to be 1:1, and the skin is ground at a speed of 20 rpm. At 1 / 2~2 / 3 of the time, at this time, the waxy matter on the surface of Cyclocarya paliurus seeds and the epidermis of the hard shell layer are worn away, and in this process, the loss rate of Cyclocarya paliurus seeds is generally below 10%. In this example it is 7%.

[0030] The concentrated sulfuric acid solution with a m...

Embodiment 3

[0034] In the present embodiment, the Cyclocarya paliurus seed treatment method uses the Cyclocarya paliurus seeds plucked from the Cyclocarya paliurus seeds planted in the Huaihua Chinese area at the end of September as raw materials. Microdermabrasion, add Cyclocarya paliurus seeds directly into the horizontal drum, and add small rubber abrasive balls and large rubber abrasive balls with a ratio of 3:1. The diameter of the small rubber abrasive balls is 2-3cm. And the diameter of big rubber grinding ball is 3~4cm, and the mass ratio of controlling grinding ball and Cyclocarya paliurus seed is 2:1, carries out grinding with the rotating speed condition of 15 revolutions / min, and the amount of grinding until the seed epidermis is cut is 1 / 2 to 2 / 3 of the thickness, at this time, the wax on the surface of the Cyclocarya paliurus seeds and the hard shell epidermis are worn off. During this process, the loss rate of Cyclocarya paliurus seeds is generally below 8%. Taking Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com