Method for discontinuously producing aerogel felt

An airgel felt, a non-continuous technology, applied in the field of airgel felt preparation, can solve the problems of uneven dipping, insufficient dipping, long preparation cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

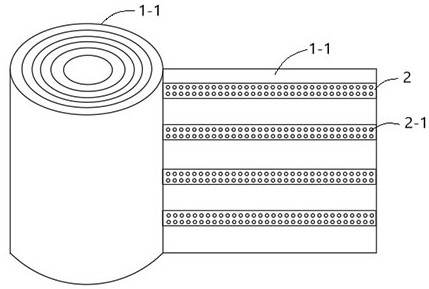

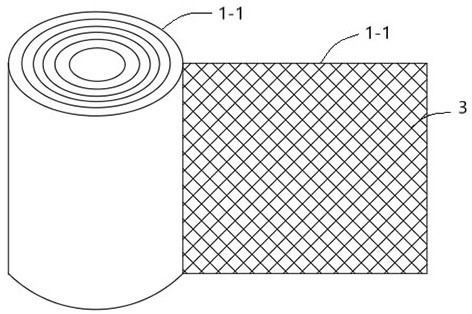

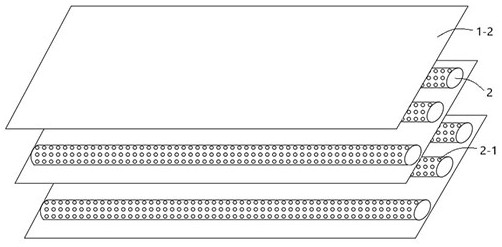

[0043] The invention provides a method for non-continuous production of airgel mats, such as Figure 1-2 shown, including:

[0044] 1) Unwind the fiber roll mat 1-1, the fibers are ceramic fibers, and several guide pipes 2 are evenly laid in the width direction of the unfolded fiber mat, and the guide pipes 2 are evenly provided with several glue injection holes 2 -1, the guide tube 2 is rolled together with the fiber felt, and the rolled fiber roll mat 1-1 has a guide tube 2 between the layers, and then placed in the dipping tank.

[0045] 2) Take tetraethoxysilane, ethanol, and water and mix evenly, wherein, in terms of molar ratio, tetraethoxysilane:ethanol:water=1:3:6; add sulfuric acid, adjust the pH value to 4, and stir evenly. Obtain silica sol; inject the silica sol between the fiber roll mats 1-1 through the glue injection hole 2-1 of the draft tube 2, impregnate the ceramic fiber mats in the silica sol, and pass the Add alkaline catalyst ammonia to the glue injecti...

Embodiment 2

[0050] A method for non-continuous production of airgel mats, comprising:

[0051] 1) Unwind the fiber roll mat 1-1, the fibers are pre-oxidized silk fibers, and several guide pipes 2 are evenly laid in the width direction of the unfolded fiber mat, and the guide pipes 2 are evenly equipped with several glue injection The hole 2-1, the guide tube 2 and the fiber mat are rewound together, and the rewound fiber roll mat 1-1 has a guide tube 2 between the layers, and then placed in the dipping tank.

[0052] 2) Mix tetraethoxysilane, ethanol, and water evenly, wherein, in terms of molar ratio, tetraethoxysilane:ethanol:water=1:4:5; then add ammonium fluoride solution and ammonia water and stir evenly, Ammonium fluoride and tetraethoxysilane are calculated by molar ratio, ammonium fluoride: tetraethoxysilane = 0.002: 1, the amount of ammonia water added is based on the molar ratio, ammonia water: tetraethoxysilane = 0.005: 1, and The catalyzed silica sol is pumped into the cataly...

Embodiment 3

[0056] A method for non-continuous production of airgel mats, comprising:

[0057] 1) Unwind the fiber roll mat 1-1, the fibers are glass fibers, and several guide pipes 2 are evenly laid in the width direction of the unfolded fiber mat, and the guide pipes 2 are uniformly provided with several glue injection holes 2 -1, the guide tube 2 is rolled together with the fiber felt, and the rolled fiber roll mat 1-1 has a guide tube 2 between the layers, and then placed in the dipping tank.

[0058] 2) Preparation of wet gel felt combined with silica wet gel: Mix tetraethoxysilane, ethanol, and water evenly, wherein, in terms of molar ratio, tetraethoxysilane:ethanol:water=1:3 : 6; then add ammonium fluoride solution and ammonia water and stir evenly. Ammonium fluoride and tetraethoxysilane are calculated by molar ratio. Calculated, ammonia water: tetraethoxysilane = 0.015: 1, to obtain the catalyzed silica sol, impregnate the glass fiber mat in the catalyzed silica sol and let it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com